A kind of low dielectric loss high frequency transmission lcp film and preparation method thereof

A high-frequency transmission and low-dielectric technology, applied in the field of LCP film production equipment, can solve the problems of inconvenient two-way rotation production, unfavorable processing output, unfavorable production operations, etc., to achieve convenient and fast stretching settings, convenient transmission work, and convenient dislocation output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A low dielectric loss high-frequency transmission LCP film, prepared from the following raw materials in parts by weight: 90 parts of functional liquid crystal polymers, 14 parts of conductive particles, 17 parts of vinyl ester resin, 56 parts of polyethylene glycol, methyl 32 parts of silicone rubber, 3 parts of dioctyl phthalate, 2 parts of graphene, 1.3 parts of p-phenylenediamine, 0.7 parts of antimony trioxide and 6 parts of γ-aminopropyl triethoxysilane.

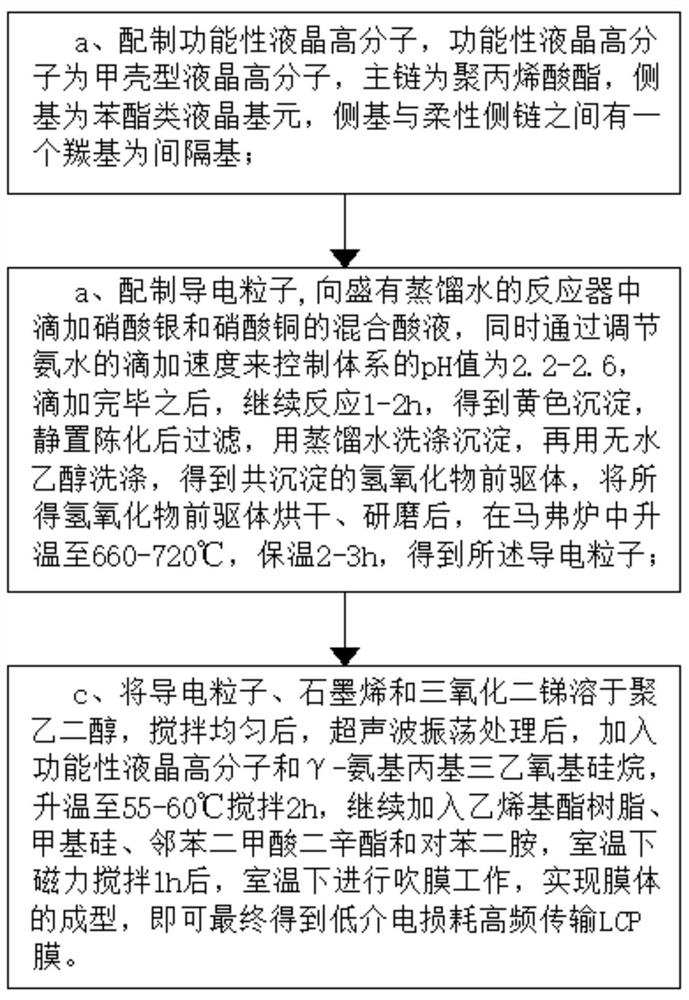

[0055] A kind of preparation method of low dielectric loss high-frequency transmission LCP film, such as figure 1 shown, including the following steps:

[0056] a. Prepare functional liquid crystal polymers. The functional liquid crystal polymers are shell-type liquid crystal polymers, the main chain is polyacrylate, and the side groups are phenyl ester mesogens. There is a carbonyl group between the side groups and the flexible side chains. Spacer;

[0057] a. Prepare conductive particles, add the mixed acid ...

Embodiment 2

[0073] On the basis of Example 1, such as Figure 12 As shown, the first workpiece 16 also includes a connecting rod 38 and a contact collar 39, the connecting rod 38 is fixedly connected to the side end position of the material inlet 21, and the side end position of the connecting rod 38 is in phase with the contact collar 39. Fixed connection.

[0074] When this embodiment is in use, the user can help to fix the connecting rod 38 through the setting of the contact collar 39, and the contact collar 39 is used for the side limit work of entering and exiting the membrane body, so as to realize the rapid movement of the membrane body. For production and cooling processing, the connecting rod 38 can help to erect and fix the feeding interface 21, realize mutual connection, and help to perform better processing and production operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com