Process for producing lithium carbonate by mixing lithium polymer and salt lake ore

A lithium polymer, lithium carbonate technology, applied in the preparation of lithium carbonate;/acid carbonate, sulfate/bisulfate, etc., can solve the problems of large waste residue, severe process conditions, and low quality of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

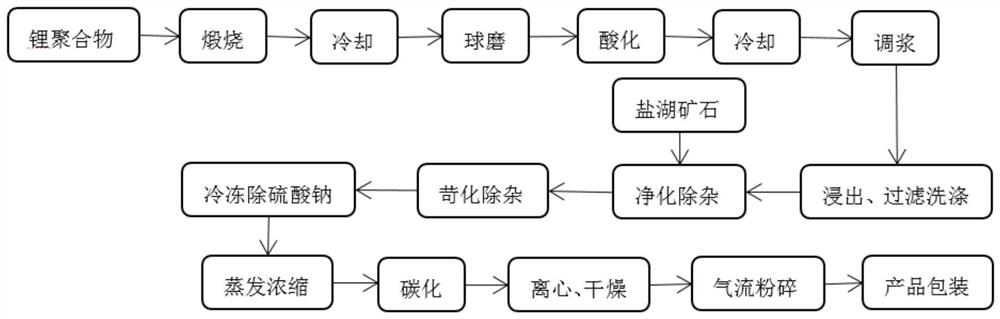

[0031]The invention is further described below with reference to the accompanying drawings, but the scope of the invention is not limited to the following.

[0032]Such asfigure 1As shown, a process for mixing lithium carbonate with lithium polymer and salt lake ore, including the following steps:

[0033]S1, the lithium polymer sequentially passes, cooled, fine mill, adding acid, cooling, the product to be added to ≤90 ° C, and the slurry solid content is 10% to 70%, thin mill solid content. The particle size is required to be 200 mesh, the calcination temperature is 1000 ~ 1250 ° C; when the acid is added, the concentration of 98% sulfuric acid, acid material ratio = 2 to 5: 1, more preferable, add the acid to 60 ° C. Hereinafter, when cooling, it is cooled in a water-cooled manner;

[0034]S2, in the slurry obtained in step S1, the calcium salt slurry is stirred and leached, and the solid content of the calcium salt slurry is 10% to 55%; the temperature ≤ 60 ° C in the leaching tank is ≤6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com