Recyclable biological carbon block and preparation method thereof

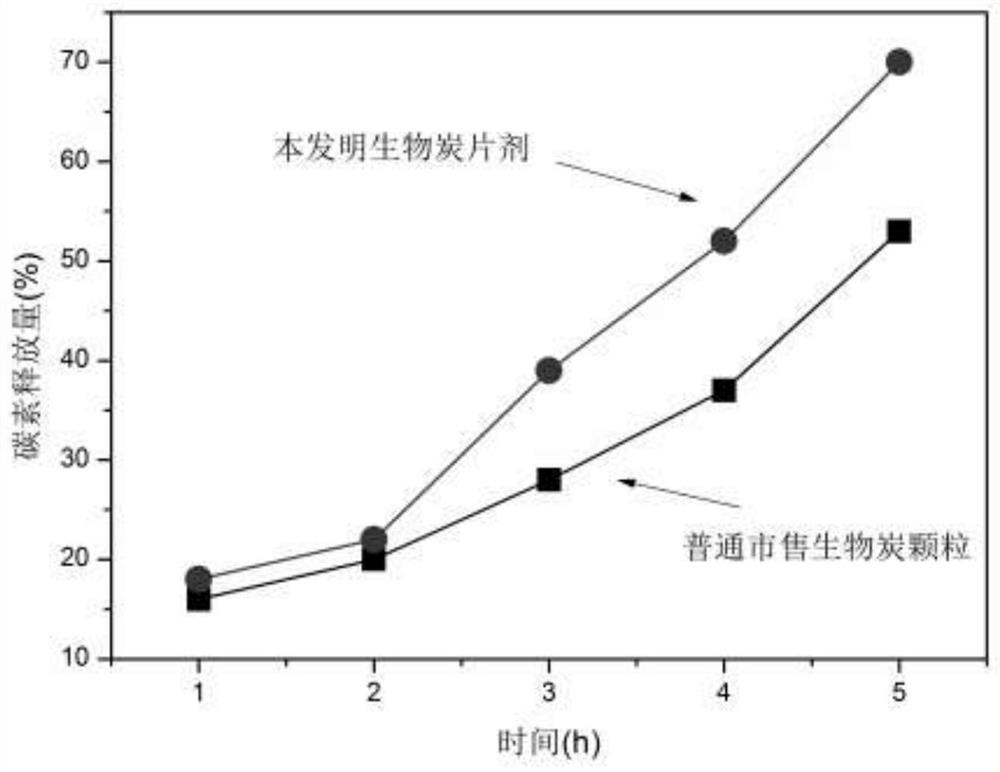

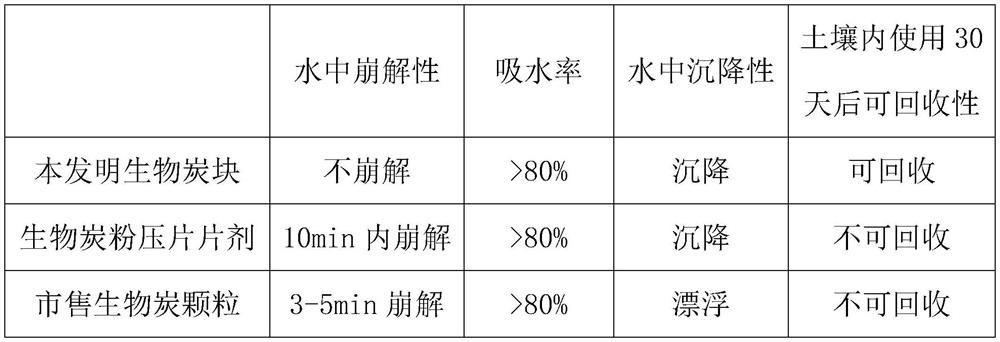

A technology of biochar and extrusion granulation, which is applied in the direction of biofuel, carbon preparation/purification, fertilizer mixture, etc., and can solve problems such as difficult recycling and easy disintegration and fragmentation of biochar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A kind of preparation method of recyclable biochar block of the present invention is implemented according to the following steps:

[0023] Step 1, weighing 25-28% of wood material, 22-28% of dry organic sludge, 25-27% of traditional Chinese medicine residue, 10-23% of sodium silicate, 5-7% of CMC-Na, the mass percentage of the above raw materials The sum is 100%;

[0024] Step 2, pulverizing the woody material, dried organic sludge, and traditional Chinese medicine residue into a solid powder mixture A with a particle size of 40-100 mesh, and sieving it for later use;

[0025] Step 3. Sodium silicate is prepared as a solution with a mass percentage of 15-30%, and CMC-Na is prepared as a solution with a mass percentage of 2-3%. After the above solution is mixed with the solid powder mixture A, pass 18 - Extrusion granulation with 22-mesh mesh, the obtained granules are dried at 55-95°C, and pressed in a mold with a pressure of 30-35KN.

[0026] Step 4. Treat the bioch...

Embodiment 1

[0028] Step 1, weighing 28% of garden prunings, 28% of dried organic sludge, 27% of discarded traditional Chinese medicine residues, 10% of sodium silicate, and 7% of CMC-Na. The sum of the mass percentages of the above raw materials is 100%.

[0029] Step 2. Grinding and sieving: crushing garden pruning, dried organic sludge, and discarded traditional Chinese medicine residue into a solid powder mixture A with a particle size of 40 meshes, and the sieved solid powder mixture A for later use.

[0030] Step 3, granulation and tabletting: the sodium silicate is prepared as a solution with a mass percentage of 15%, and the CMC-Na is prepared as a solution with a mass percentage of 3%. After the above solution is mixed with the solid powder mixture A, pass Extrusion granulation with 18-mesh mesh, the obtained granules were dried at 55°C, and pressed in a mold with a pressure of 30KN.

[0031] Step 4. Treat the biochar material obtained in the above step 3 under nitrogen protection...

Embodiment 2

[0033] Step 1. Weigh 25% of corncobs, 22% of dried organic sludge, 25% of discarded traditional Chinese medicine residues, 23% of sodium silicate, and 5% of CMC-Na. The sum of the mass percentages of the above raw materials is 100%.

[0034] Step 2. Grinding and sieving: crushing garden pruning, dried organic sludge, and waste traditional Chinese medicine residue into a solid powder mixture A with a particle size of 100 meshes, and sieving the solid powder mixture A for later use.

[0035] Step 3, granulation and tabletting: prepare sodium silicate as a solution with a mass percentage of 30%, and CMC-Na as a solution with a mass percentage of 2%, after mixing the above solution and solid powder mixture A uniformly, pass Extrusion granulation with 22-mesh mesh, the obtained granules were dried at 95°C, and pressed in a mold with a pressure of 35KN.

[0036] Step 4. Treat the biochar material obtained in the above step 3 under nitrogen protection at 300° C. for 6 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com