Continuous steel machining device

A technology for processing equipment and steel materials, which is applied in the field of continuous steel processing equipment, and can solve problems such as the inability to realize the discharge of angle steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

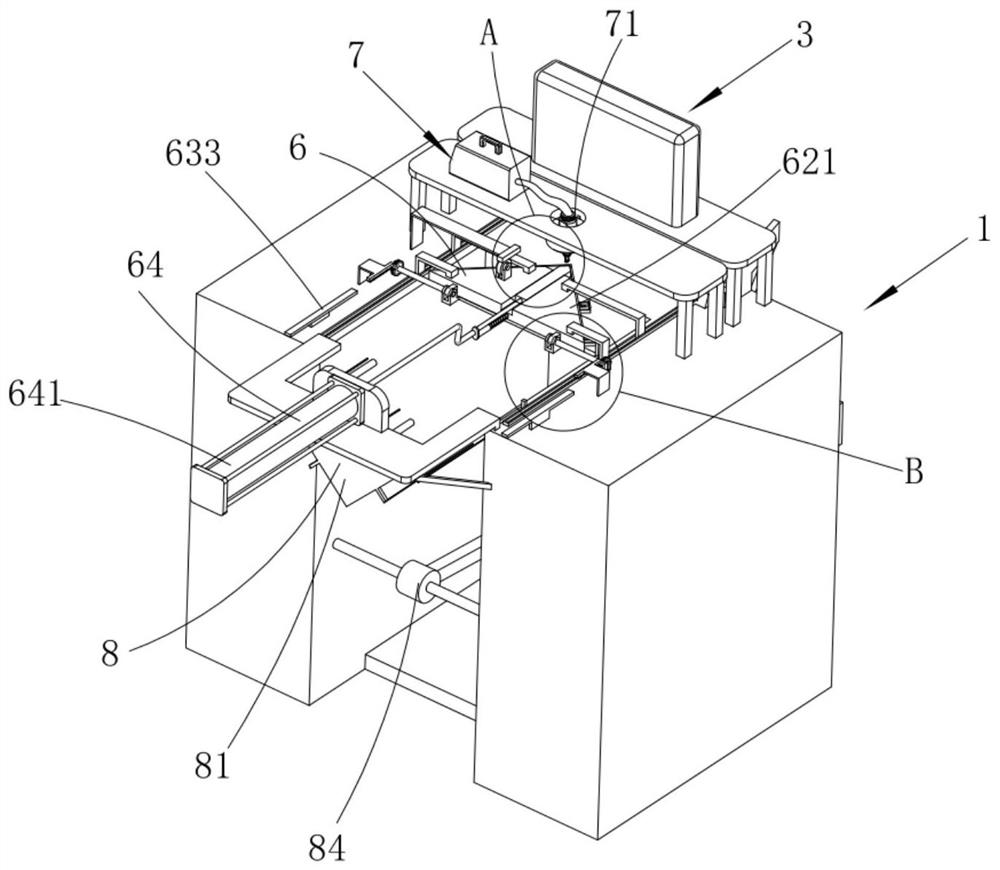

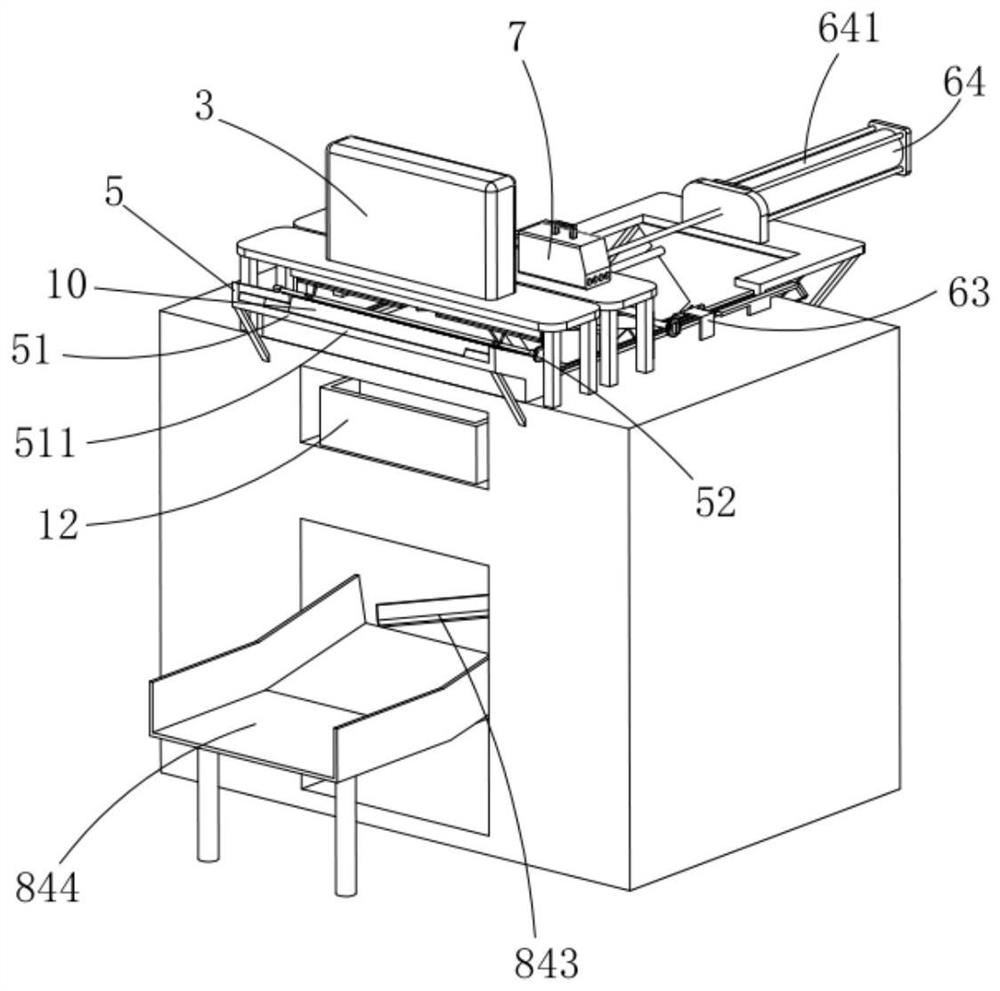

[0047] Such as figure 1 and figure 2 As shown, a continuous processing equipment for steel includes a workbench 1, a lower die 2 installed on the workbench 1, and an upper die 4 that is power-connected with the stamping equipment 3 and is facing the lower die 2. The lower die 2 The bottom is provided with a punching groove 21, and the bottom of the upper die 4 is provided with a punch 41 corresponding to the punching groove 21, and also includes:

[0048] Feeding device 5, said feeding device 5 includes a material shifting assembly 51 arranged on one side of said lower die 2 and a control assembly 52 that drives and connects said dialing assembly 51 and said upper die 4;

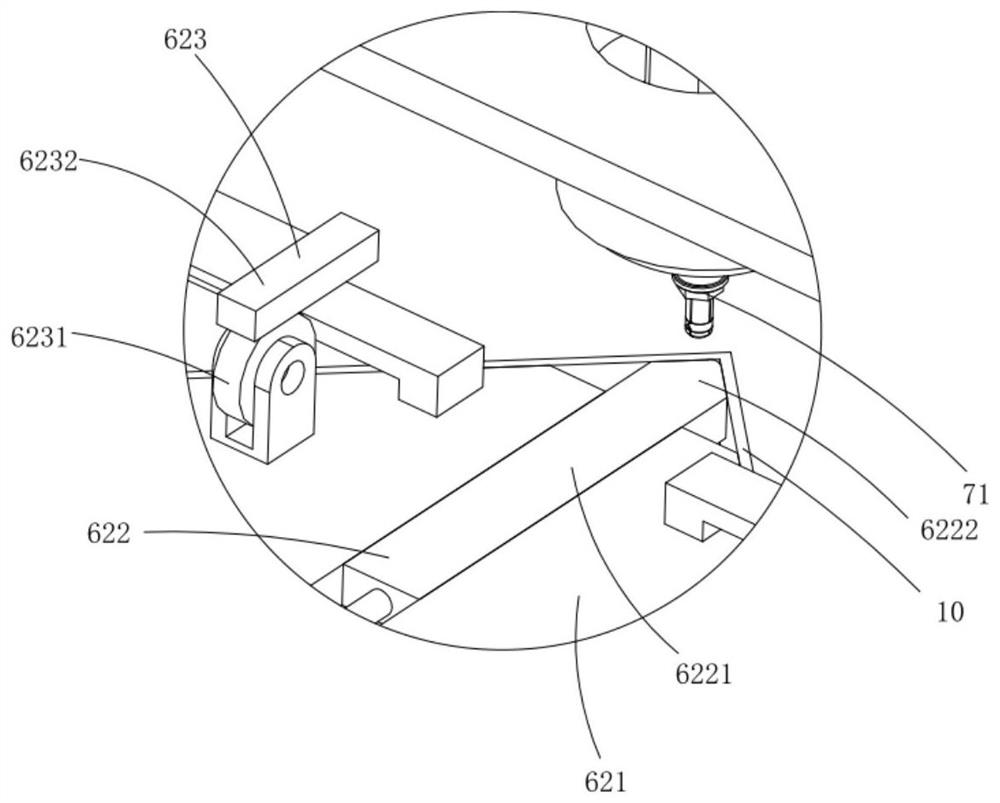

[0049] Bending device 6, said bending device 6 includes a mold base 61 that transitionally connects said lower die 2 and said material shifting assembly 51 and a mold base 61 that is slidably arranged on said workbench 1 and correspondingly cooperates with said mold base 61 The die assembly 62, the fasten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com