Light anti-seismic floor slab connecting joint and using method thereof

A technology for connecting nodes and floors, applied in the directions of floors, shockproof, building components, etc., can solve the problems of poor installation stability, reduced work efficiency, cumbersome installation process, etc., to prevent rebound, ensure stability, and ensure the effect of normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

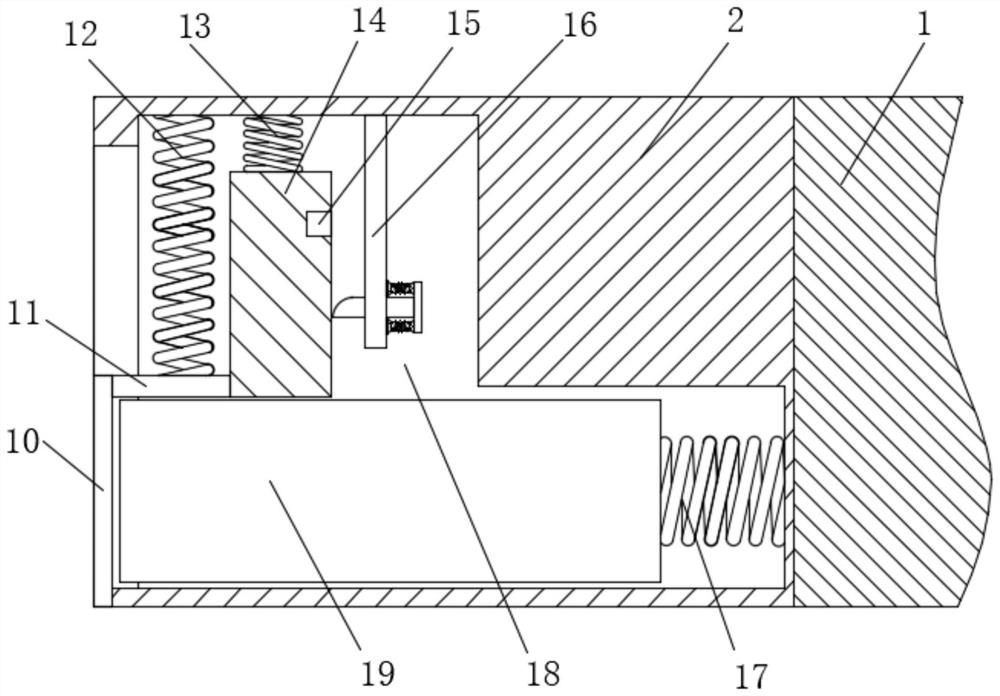

[0043] Such as Figure 1-10 As shown, a light-weight earthquake-resistant floor connection node includes a floor body 1 and a concrete embedded block 6. Both sides of the floor body 1 are fixedly connected with connection boxes 2, and the sides of the two connection boxes 2 that are far away from each other are provided with The second installation groove 18, the two second installation grooves 18 are misplaced, and the inside of the second installation groove 18 is provided with a connection assembly for connecting two floor slab bodies 1, and the inside of the concrete pre-embedded block 6 is provided with a connection hole 3 and The first installation groove 7, the connection hole 3 and the first installation groove 7 are connected, the inside of the first installation groove 7 is provided with a fixing assembly for fixing the connection assembly, and both sides of the concrete embedded block 6 are provided with Z-shaped grooves 24 , the inside of the Z-shaped groove 24 is ...

Embodiment 2

[0052] This embodiment is improved on the basis of Embodiment 1: as Figure 1-10 As shown, including the floor body 1 and the concrete embedded block 6, the two sides of the floor body 1 are fixedly connected with the connection box 2, and the side of the two connection boxes 2 away from each other is provided with a second installation groove 18. The second installation groove 18 is arranged in a misplaced position. The inside of the second installation groove 18 is provided with a connecting assembly for connecting two floor slab bodies 1. The inside of the concrete pre-embedded block 6 is provided with a connecting hole 3 and a first installing groove 7. The connecting hole 3 It communicates with the first installation groove 7, and the inside of the first installation groove 7 is provided with a fixing assembly for fixing the connection assembly. Both sides of the concrete pre-embedded block 6 are provided with Z-shaped grooves 24, and the inside of the Z-shaped groove 24 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com