High-temperature-resistant dust removal ceramic filter element

A ceramic filter element and high-temperature-resistant technology, which is applied to fixed filter element filters, filtration separation, separation methods, etc., can solve the problems of inconvenient cleaning of dust and impurities inside the filter element, poor high-temperature resistance of the filter element, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

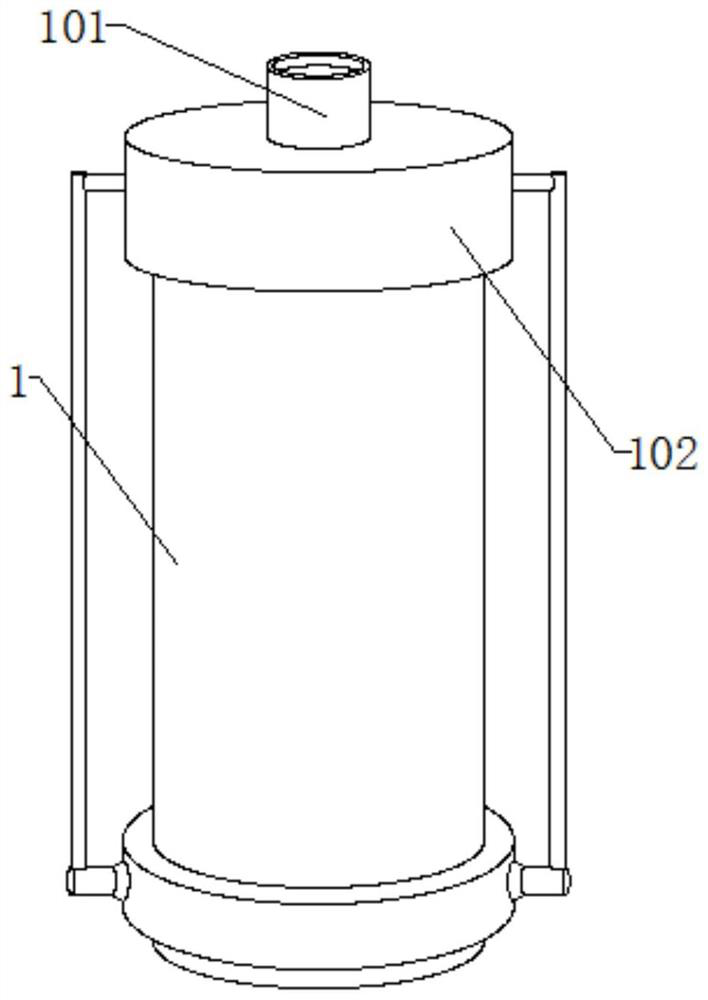

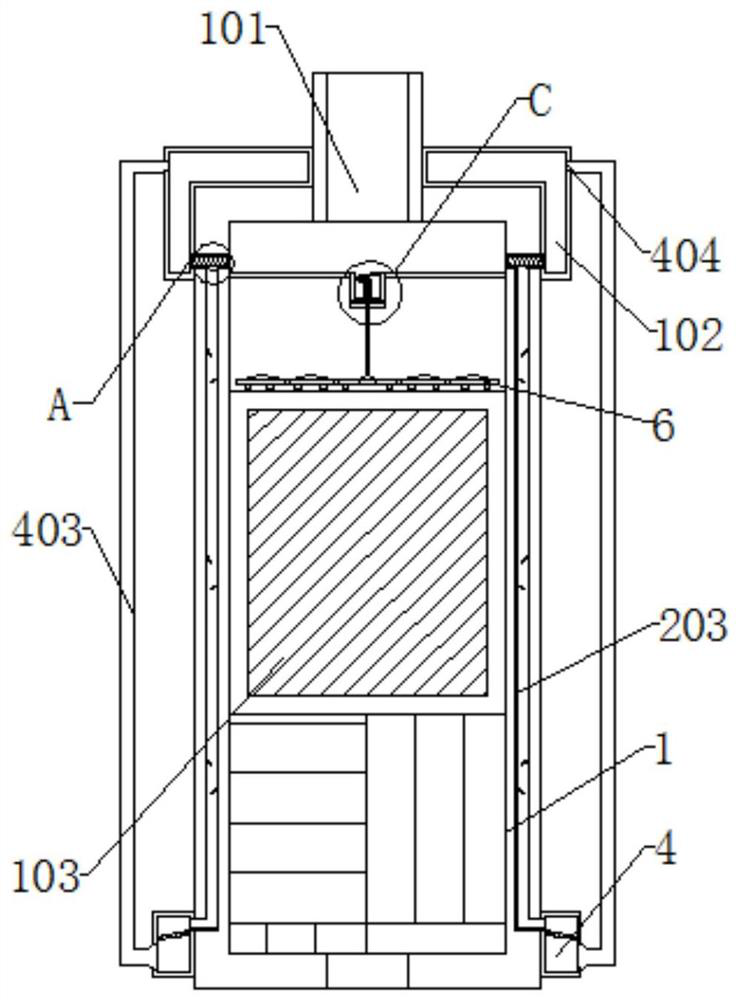

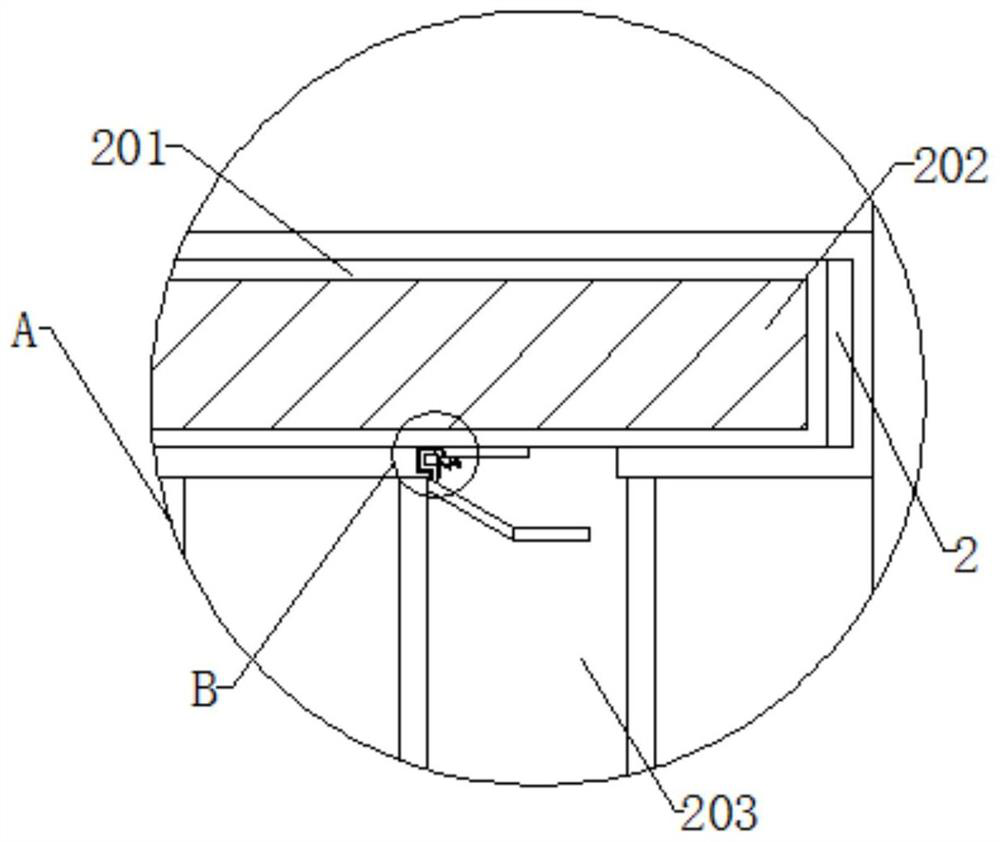

[0030] Embodiment 1: A high-temperature-resistant and dust-removing ceramic filter element, including a casing 1, a water inlet pipe 101 runs through the upper end of the casing 1, a water storage rack 102 surrounds the upper end of the casing 1, and a filter layer 103 runs through the inside of the casing 1 to store water. The inner side of the lower end of the frame 102 runs through a through cavity 2, and the inside of the through cavity 2 is inlaid with a glass tube 201. The inside of the glass tube 201 is filled with mercury 202, and the lower end of the through cavity 2 is penetrated with a water delivery pipe 203. The thickness of the inner wall of the glass tube 201 is 0.2 -0.5cm, the water pipe 203 runs through the inner wall of the shell 1, and the inner diameter of the water pipe 203 is 0.5-1cm, when the internal temperature of the shell 1 is higher than 40°, the mercury expands and the glass pipe 201 breaks;

[0031] Among them: fill the inside of the water storage ...

Embodiment 2

[0032] Embodiment 2: A water inlet pipe 101 runs through the upper end of the casing 1, a water storage rack 102 surrounds the upper end of the casing 1, a filter layer 103 runs through the inside of the casing 1, and a through cavity 2 runs through the inner side of the lower end of the water storage rack 102, which penetrates A glass tube 201 is inlaid inside the cavity 2, and the inside of the glass tube 201 is filled with mercury 202. A water delivery pipe 203 runs through the lower end of the cavity 2, and a rotating sphere 301 is hinged at the upper end of the water delivery tube 203 close to the glass tube 201. One part of the rotating sphere 301 There is a baffle 3 for side swing, the lower end of the baffle 3 is elastically connected with a spring 304, the side of the rotating sphere 301 away from the baffle 3 swings with a bracket 302, the lower end of the bracket 302 is inlaid with a swing frame 303, and the lower end of the water delivery pipe 203 runs through a The...

Embodiment 3

[0034] Embodiment 3: the upper end of the water delivery pipe 203 is hinged close to the glass tube 201 with a rotating sphere 301 , one side of the rotating sphere 301 swings with a baffle 3 , the lower end of the baffle 3 is elastically connected with a spring 304 , and the rotating sphere 301 is far away from the side of the baffle 3 There is a bracket 302 for side swing, the lower end of the bracket 302 is inlaid with a swing frame 303, the lower end of the water pipe 203 runs through a water collecting frame 4, the two sides of the water collecting frame 4 run through a pipe 403, and the inside of the water collecting frame 4 is embedded with a screen 401, the upper and lower ends of the pipe 403 are respectively penetrated with a water outlet 404 and a water inlet 402, the water outlet 404 is connected with the water storage frame 102, the upper end of the shell 1 is installed with a fixed frame 5, and the upper end of the fixed frame 5 is embedded with a guide A plate 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com