A kind of n-type highly conductive Si-based negative electrode material and preparation method thereof

A high-conductivity, negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of easy gasification and volatilization of doping sources, and achieve easy control of phosphorus doping amount, high conductivity, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of n-type highly conductive Si-based negative electrode material, comprising the following steps:

[0029] 1. Take 0.5g Mg 2 Si, 2.6g AlBr 3 , 0.5g (NH 4 ) 2 HPO 4 Add 50ml of cyclohexane solution, mix evenly, transfer to the reaction kettle, pass nitrogen into the reaction kettle to exhaust the air, keep it at 180°C for 24h; after the reaction, wash the sample and dry it.

[0030] 2. Put the dried product into 50% hydrochloric acid solution, pickle and stir for 6 hours, then wash the sample with deionized water, and dry it in a 60°C oven to obtain the product, which is to be tested.

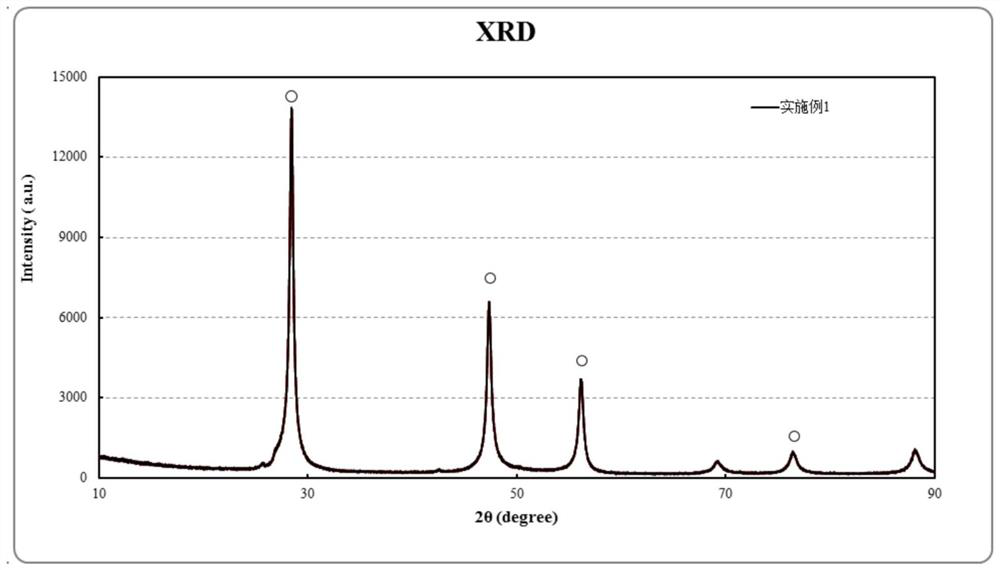

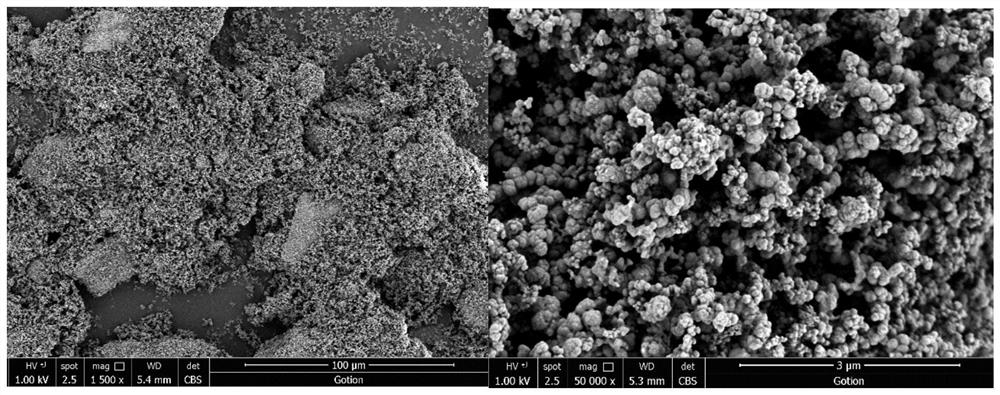

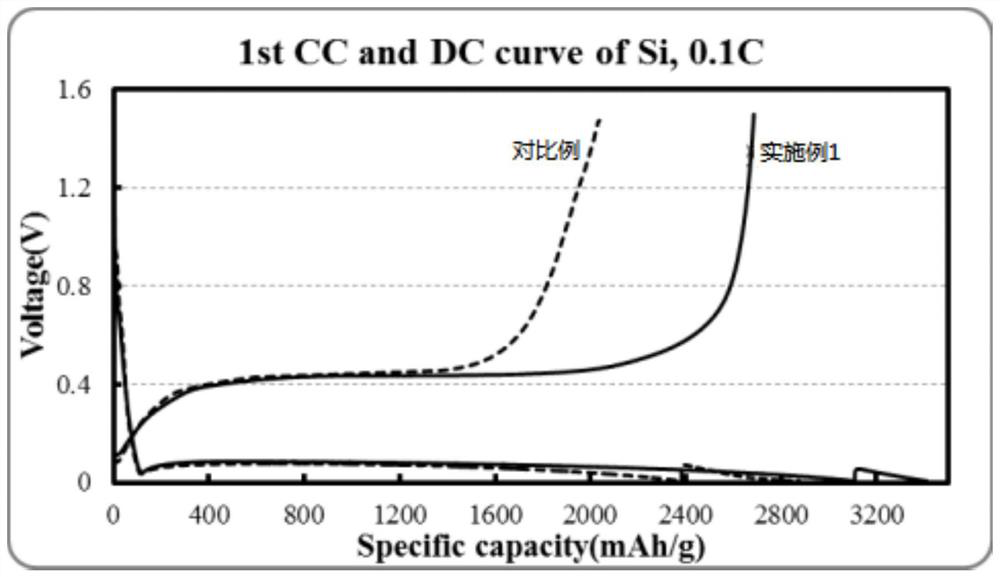

[0031] The prepared Si-based materials were characterized by XRD such as figure 1 As shown, where "O" represents the peak, representing the peak of Si in the XRD pattern, from figure 1 It can be seen that the prepared Si-based material corresponds to the Si spectrum; from figure 2 It can be seen that the prepared n-type Si-based material is in the shape of sph...

Embodiment 2

[0033] A preparation method of n-type highly conductive Si-based negative electrode material, comprising the following steps:

[0034] 1. Take 0.5g Mg 2 Si, 2.4g AlBr 3 , 1.5g Na 3 PO 4 Add 50ml of cyclohexane solution, mix evenly, transfer to the reaction kettle, pass nitrogen into the reaction kettle to discharge the air, keep the reaction at 160°C for 48h; after the reaction, wash the sample and dry it.

[0035] 2. Put the dried product into 50% hydrochloric acid solution, pickle and stir for 5 hours, then wash the sample with deionized water, and dry it in an oven at 60°C to obtain the product.

Embodiment 3

[0037] A preparation method of n-type highly conductive Si-based negative electrode material, comprising the following steps:

[0038] 1. Take 0.5g Mg 2 Si, 3.4g AlBr 3 , 2.2g NH 4 h 2 PO 4 Add 50ml of cyclohexane solution, mix evenly, transfer to the reaction kettle, pass nitrogen into the reaction kettle to discharge the air, keep the reaction at 200°C for 10h; after the reaction, wash the sample and dry it.

[0039] 2. Put the dried product into 50% hydrochloric acid solution, pickle and stir for 8 hours, then wash the sample with deionized water, and dry it in an oven at 60°C to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com