Ultrasonic partial discharge detection robot applied to AIS equipment of power plant

A partial discharge detection, ultrasonic technology, applied in the direction of using acoustic measurement for testing, instruments, motor vehicles, etc., can solve the problems of undetectable discharge intensity, subjective emotional influence of guards, limited application range, etc., to facilitate follow-up investigation and Effects of analyzing work, improving inspection efficiency and quality, and shortening response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

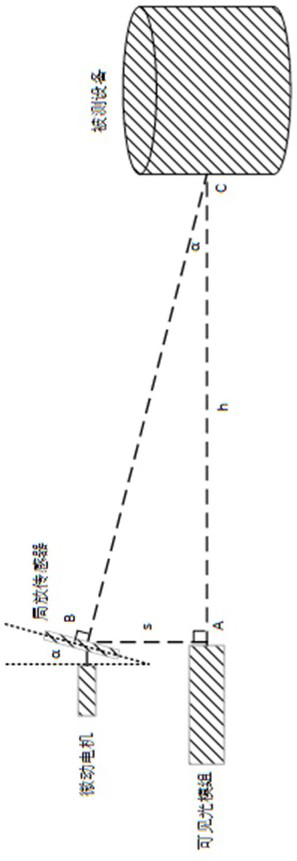

[0038] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 7 As shown, the ultrasonic partial discharge detection robot applied to AIS equipment in power plants includes a robot body 9 and a background monitoring module 1, and a main control module 2, a detection module 3, a drive module 4, a power supply module 5, and a main control module 2 are installed on the robot body 9. Communication module 6, navigation obstacle avoidance module 7 and storage module 8, wherein, main control module 2, drive module 4, power supply module 5, communication module 6 and storage module 8 are installed in the robot body 9, detection module 3 is installed in the robot body On the upper surface of 9, the navigation obstacle avoidance module 7 is installed on and around the upper surface of the robot body 9, the detection module 3, the drive module 4, the power supply module 5, the navigation obstacle avoidance module 7 and the storage module 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com