Fabricated prestressed hollow slab floor construction supporting system and construction method

A support system and prestressing technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of unreasonable lateral stiffness, reduced engineering consumption, and overconservation, etc., to achieve Easy disassembly, simple support system, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

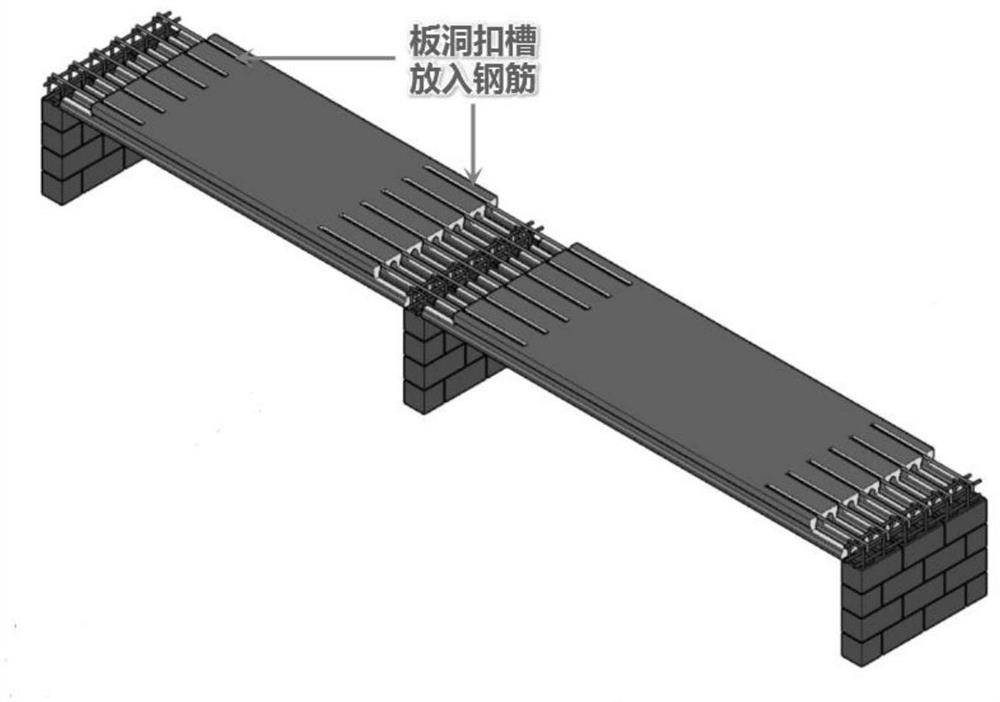

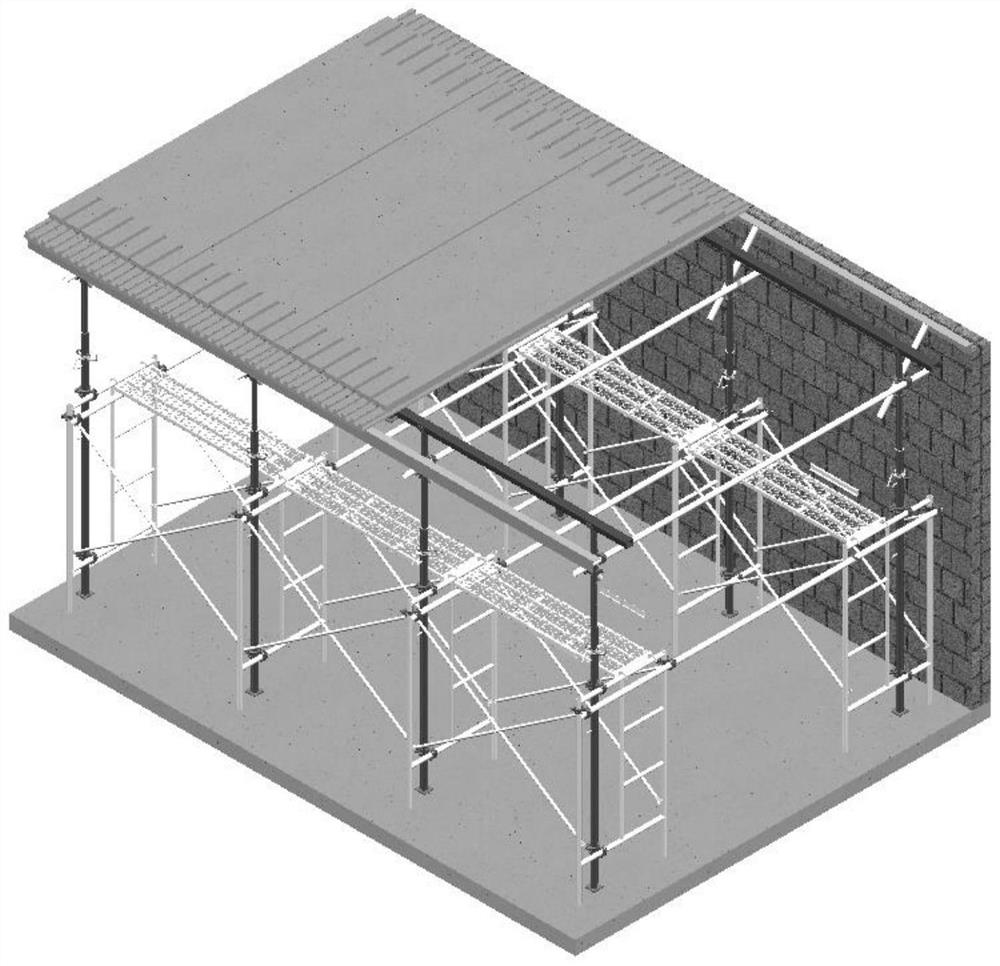

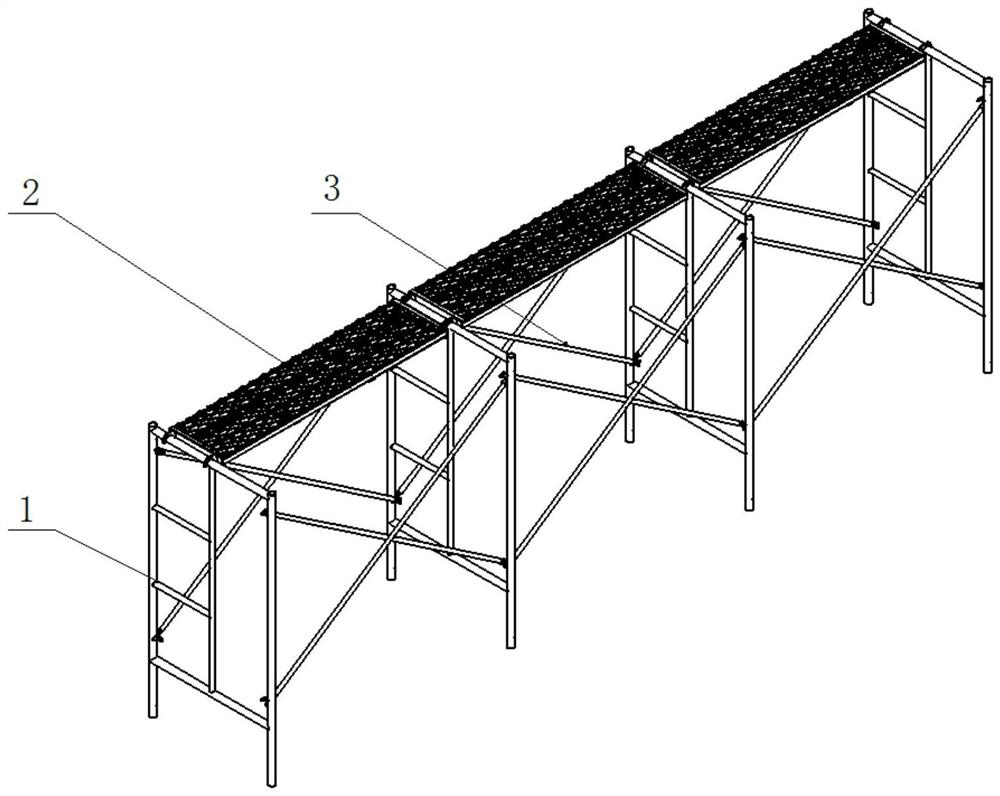

[0041] Specific implementation mode one: see Figure 1-8This embodiment will be described. The pre-stressed hollow slab floor construction support system described in this embodiment includes several support units connected to form a support system, and each support unit includes two portal scaffolds 11 and four steel support roofs 9 , rotating buckle 10, two supporting beams 13 and ring beam formwork angle steel 15, two portal scaffolds 11 are arranged oppositely, and both sides of each portal scaffolding 11 are fixed with steel supporting top 9 by rotating buckle 10, both sides Support beams 13 are installed in the top U-shaped groove of the steel roof 9, and the prestressed hollow slabs are placed on the two support beams 13, and both sides are supported by ring beam support formwork angle steels 15.

[0042] Described portal scaffold 11 comprises several scaffold frames 1, pedals 2 and some pull rods 3, pedals 2 are fixed on some scaffold frames 1, and pull rods 3 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com