External culvert structure adapted to variable incoming flow angle low loss adjustable support plate

A culvert and angle technology, applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of large geometric curvature, large flow loss of the second culvert strut, and large thickness of the second culvert strut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

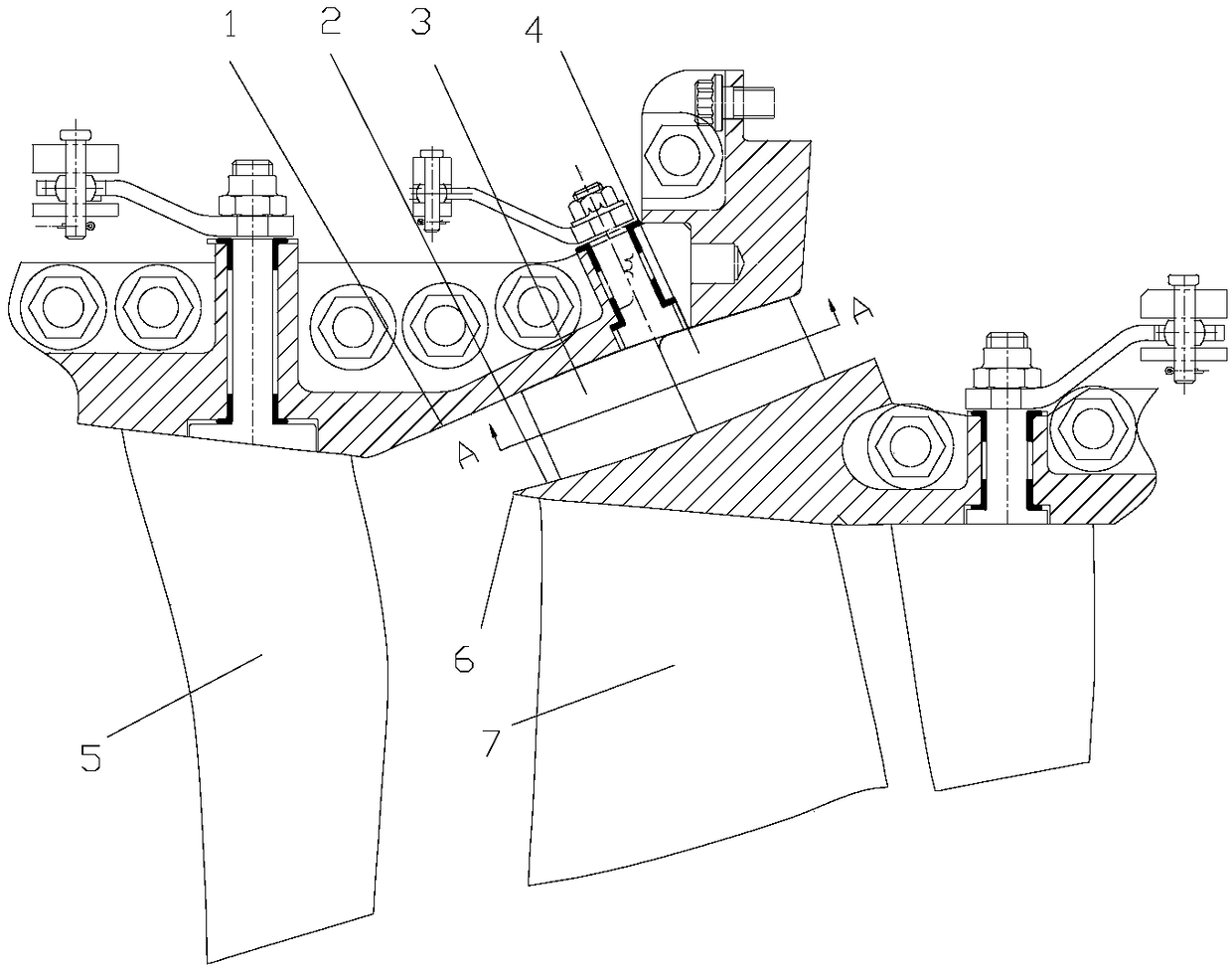

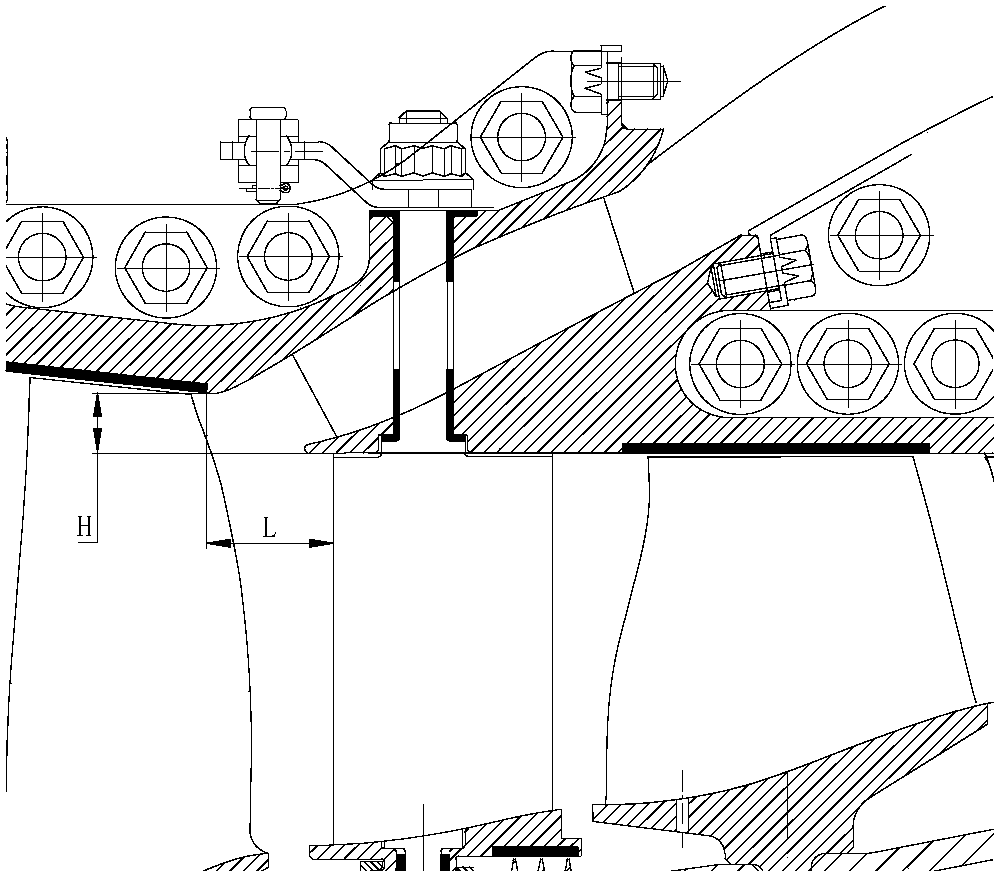

[0014] Re-select the position of the inlet section of the second outer culvert, and set the inlet of the second outer culvert on the casing between the outlet of the CDFS stator (5) and the inlet of the high-pressure compressor rotor (7), inside the support plate of the second outer culvert There is no longer an adjustment shaft passing through, and the thickness of the support plate of the second outer culvert is reduced, which is beneficial to reducing the flow loss in the second outer culvert.

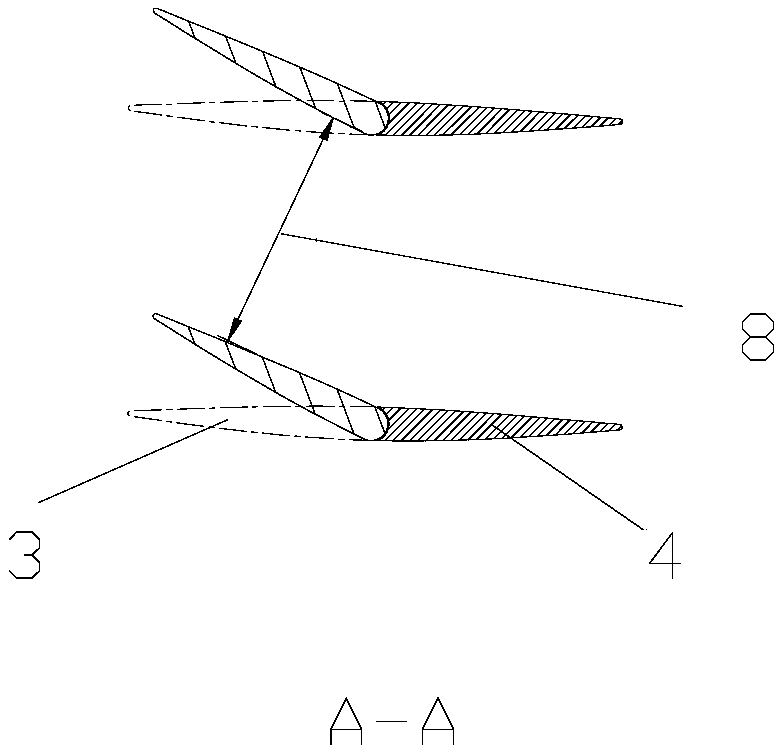

[0015] The difference between the axial width and the radial height at the inlet of the second outer culvert is small, and the area of the inlet of the second outer culvert must be increased as much as possible under the premise of ensuring a uniform flow field at the inlet of the high-pressure compressor. In the design of the second outer culvert runner, there is a certain angle between the second outer culvert runner and the axial direction, and the radial height of the second ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com