Essence extraction method and essence extraction device

A technology of extraction device and extraction method, which is applied in the direction of essential oil/fragrance, fat production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiments of the present application provide a method for extracting essence, comprising the steps of:

[0043] Step 100, radiatively heating the extract in a vacuum environment (specifically, a high-frequency excitation oscillator can be used to heat the target collection, of course, it is not limited to this, and other types of high-frequency generators can also be used. The premise is that thermal radiation heating can be realized);

[0044] In step 200, the cell walls of the extract are broken, and the molecular clusters of the active ingredients escape gradually, and then are adsorbed on the cooled collection surface to form the target collection.

[0045] Specifically, after step 100 and before step 200, the following steps are included: according to the high-performance liquid chromatography analysis of the components of the extract, the height of the collection surface is adjusted for different target collections, so as to obtain the maximum collection amount ...

Embodiment 2

[0077] The embodiment of the present application also provides an essence extraction device, which is based on the essence extraction method described in the first embodiment above, and therefore has all the beneficial technical effects of the method, and will not be repeated here.

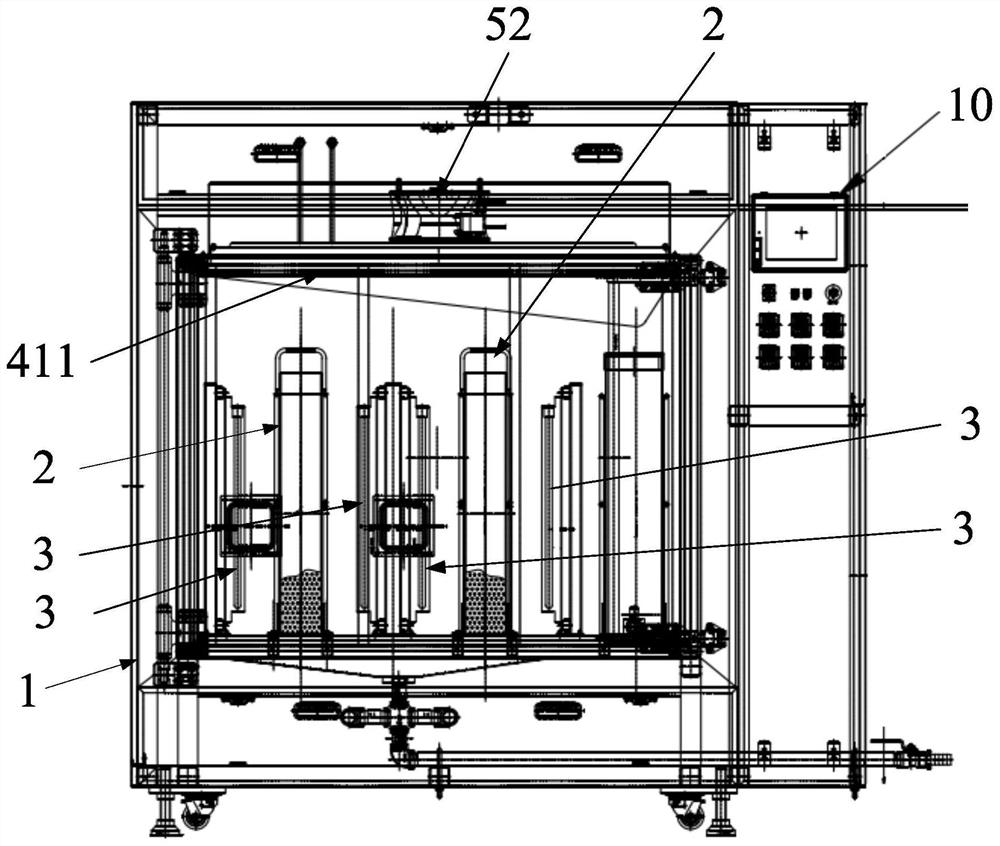

[0078] In this embodiment, preferably, as figure 1 with figure 2 As shown, the essence extraction device includes a bin body 1, a storage component 2, a radiation heating component 3, an attachment assembly 4, and a cooling assembly 5; Inside, the cooling assembly 5 is arranged outside the warehouse body 1;

[0079] The bin body 1 is used to form a vacuum; the holding member 2 is used to hold the extracted object; the radiation heating member 3 is used to radiately heat the extracted object placed in the holding member 2;

[0080] The attachment assembly 4 is arranged above the holding member 2 along the height direction of the bin body 1, and the attachment assembly 4 is formed with a collecti...

Embodiment 3

[0103] The embodiment of the present application also provides an essence extraction device, which is based on the essence extraction method described in the first embodiment above, and therefore has all the beneficial technical effects of the method, and will not be repeated here.

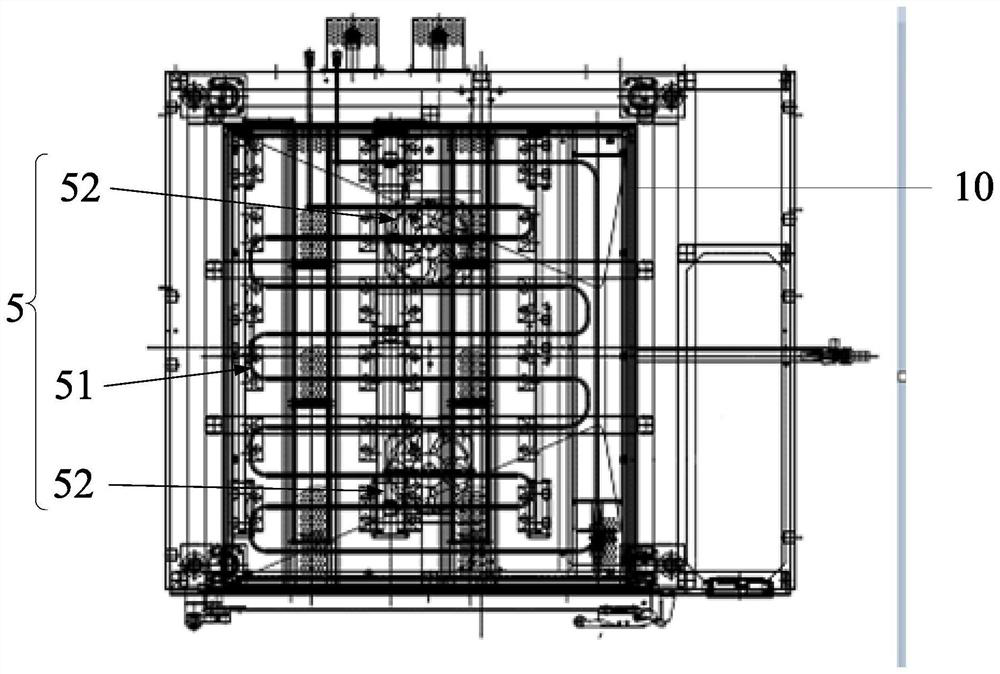

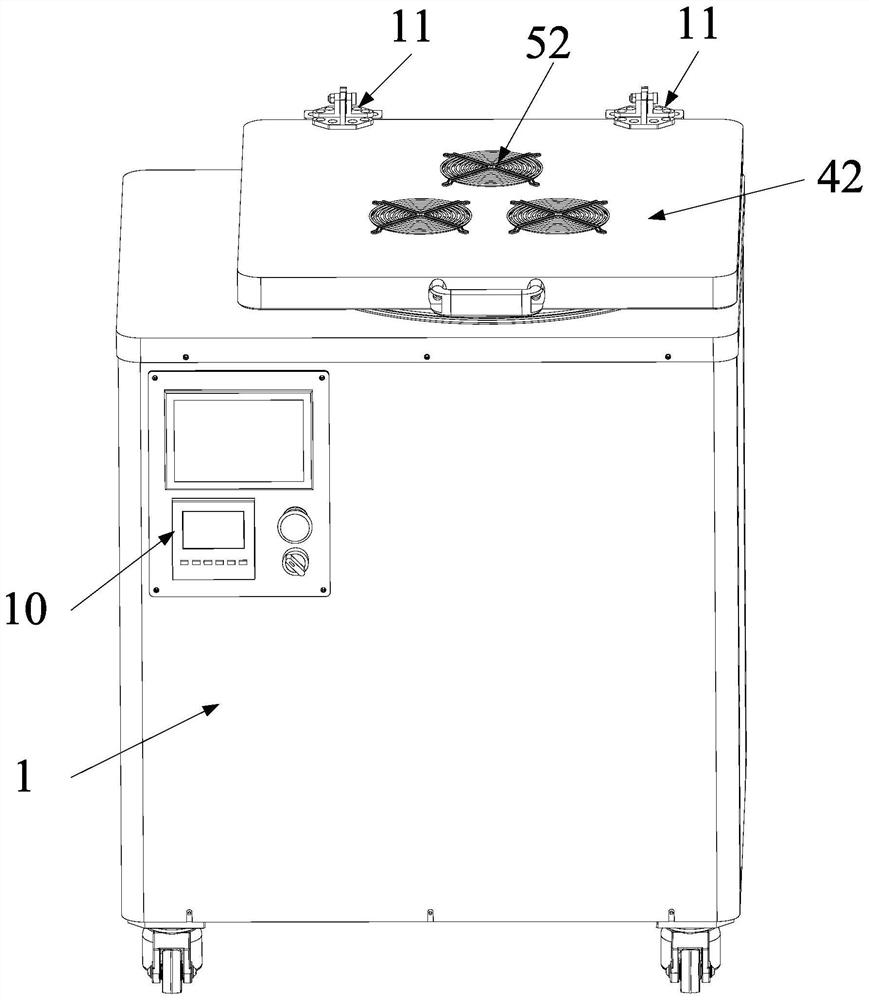

[0104] In this embodiment, preferably, as Figure 3 to Figure 8 As shown, the essence extraction device includes a bin body 1, a holding component 2, a radiation heating component 3, an attachment component 4 and a cooling component 5;

[0105] Among them, the holding member 2, the radiation heating member 3 and the attachment assembly 4 are arranged inside the bin body 1, and the cooling assembly 5 is arranged outside the bin body 1; the bin body 1 is used to form a vacuum; the holding member 2 is used to hold Extracted;

[0106] The radiation heating member 3 is used to radiate heat the extract placed in the holding member 2; the attachment assembly 4 is arranged above the holding member 2 alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com