Two-stage continuous natural gas hydrate preparation system based on torque measurement

A torque measurement and preparation system technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of unable to quickly prepare a large number of hydrate crystal nuclei, high-density formation of natural gas hydrate, lack of devices for simultaneous gas separation, etc., to achieve Save cost, reduce heat exchange, and not easy to rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

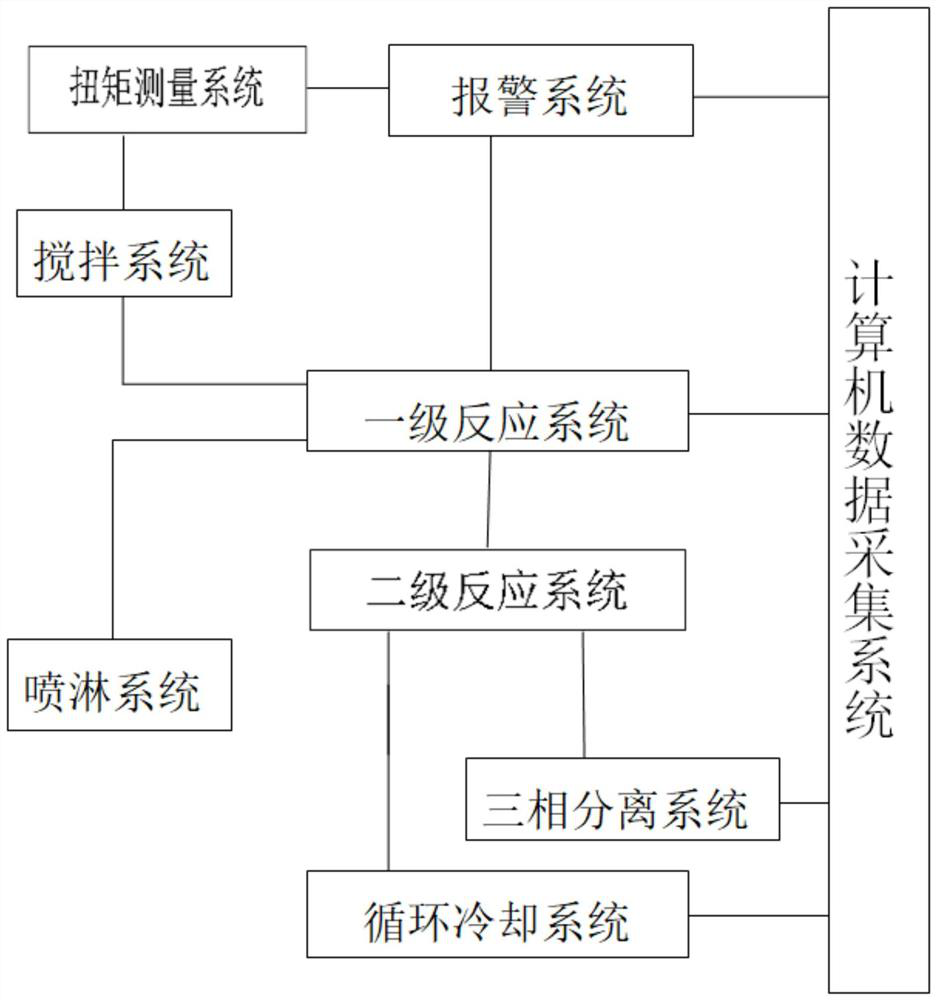

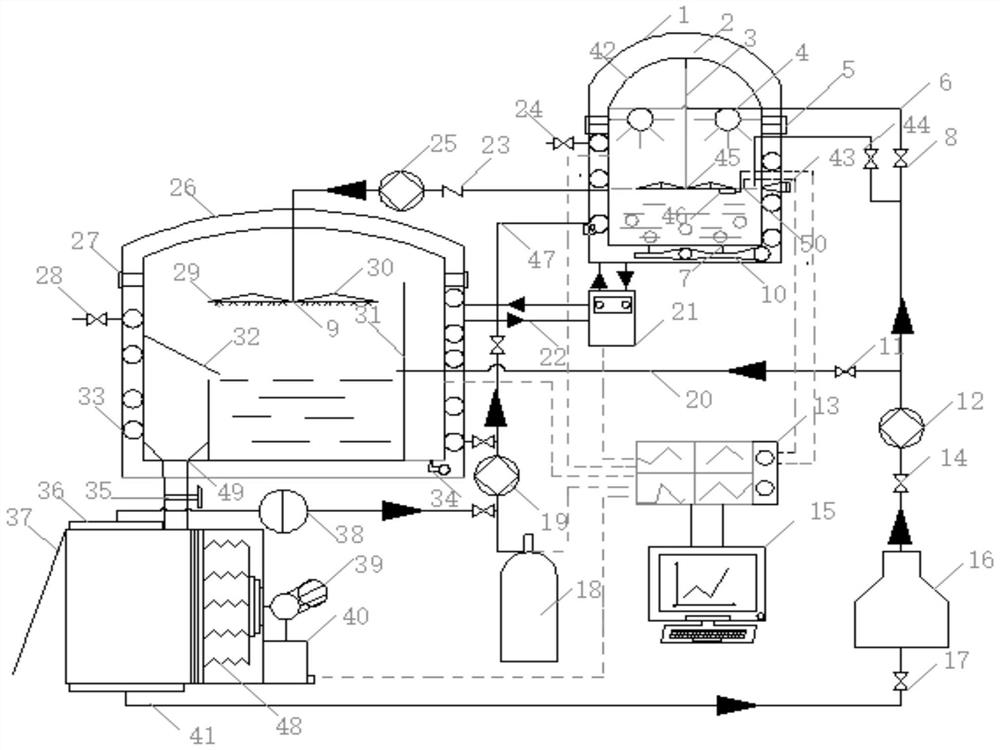

[0025] figure 1 Shown is the working principle block diagram of the two-stage continuous natural gas hydrate preparation system and device based on torque measurement. The working process is as follows: first open the circulating cooling system, inject gas to increase the pressure, form a high-pressure and low-temperature environment, and then open the two-stage reaction The primary reactor mixes natural gas and spray water under high pressure and low temperature to form hydrate nuclei. According to the torque of the stirring blade and the prompt of the alarm system, the slurry enters the secondary reactor, and the natural gas generates hydrate, which enters To the three-phase separation system, hydrate storage, gas-liquid recovery. The torque signal, pressure signal, temperature signal and liquid level height duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com