Coal gas cycle coal pyrolysis coupled chemical chain gasification system for co-production of oil and gas

A technology of gasification system and chemical chain, applied in the field of coal cascade conversion co-production tar and synthesis gas process system, can solve the problems of device blockage, oxygen carrier coking, high cost, etc., achieve high efficiency utilization, energy utilization efficiency improvement, The effect of enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

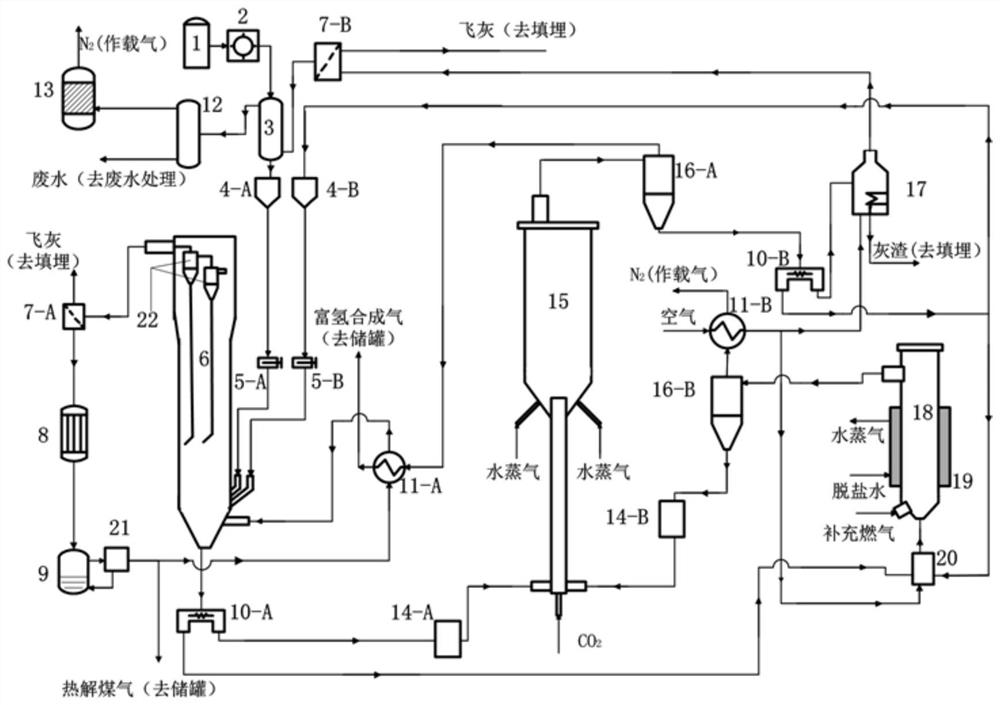

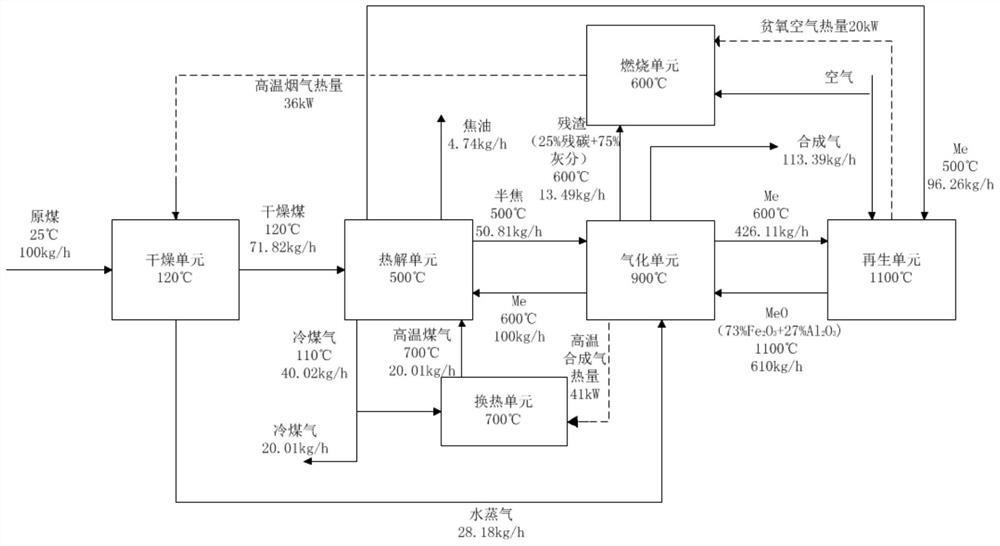

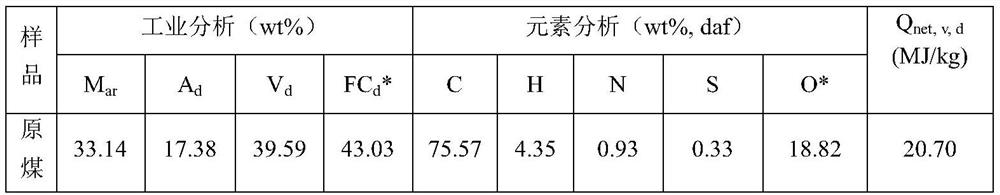

[0057] Embodiment 1: the present embodiment uses the above-mentioned lignite as raw material, Fe 2 o 3 / Al 2 o 3 (73wt% / 27wt%) is the oxygen carrier. See attached for specific operation process figure 1 ; The feed rate is 100kg / h. The raw coal is crushed and sieved into fine powder of 0.075mm, and then enters the drying reactor, where it is mixed with the 600°C high-temperature flue gas from the residual carbon combustion furnace and the regenerative reactor flue gas after heat exchange. Drying, the temperature of the dryer is 120°C, at this temperature, the external water of the coal sample can be fully removed, and no pyrolysis reaction occurs, and the dried coal sample enters the pyrolysis reactor. The water-containing flue gas is separated from the waste water through the gas-liquid separation tank. After the sewage treatment, the waste water can be transported to the gasification unit as a gasification agent or as condensed water in public works; the flue gas is passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com