Flexible composite glass and preparation method thereof

A composite glass and flexible glass technology, applied in coating and other directions, can solve the problems of inability to realize automatic production, high production cost, and many manual participation, and achieve the effect of realizing automatic mass production, reducing production costs, and improving product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

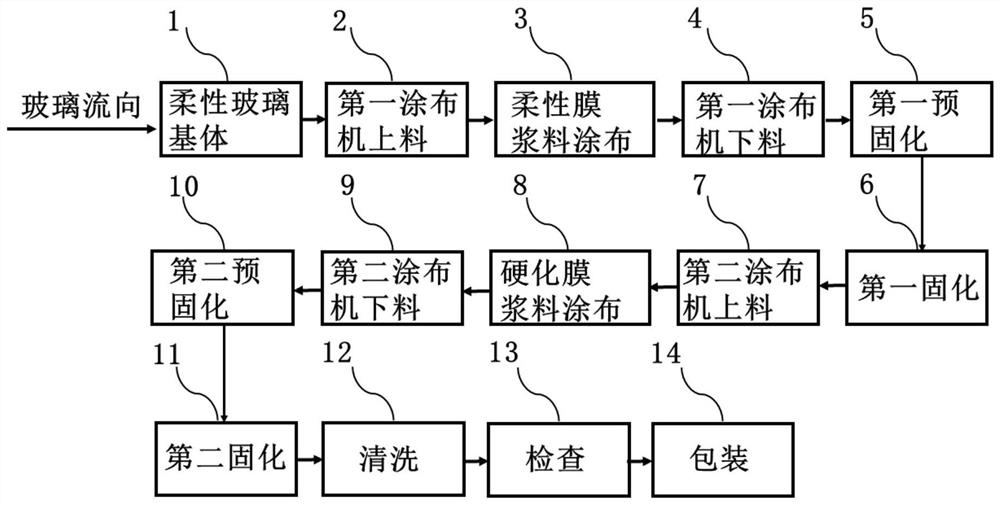

Method used

Image

Examples

Embodiment 1

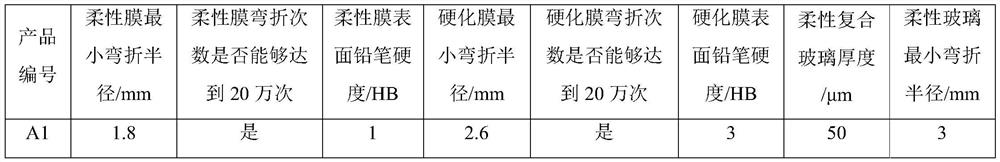

[0077] The flexible glass substrate is taken out by automatic equipment and sent to the first coating machine to prepare the first coating machine for loading. The thickness of the flexible glass substrate is 30 μm. The delivered flexible glass substrate is placed on the first coating machine by a three-axis manipulator or a robot with a manipulator arm for flexible film slurry coating. The composition of the flexible film slurry is: polyimide, polyethylene terephthalate, polypropylene film and dimethylacetamide, and the viscosity at 24°C is 9000cps. The first coating machine chooses the mechanical structure suitable for the flow operation of the production line, and the coating form of the first coating machine is slit coating. After the coating of the flexible film slurry is finished, the first coater is unloaded using the same equipment as the first coater. The flexible glass substrate coated with the flexible film slurry is transported to the first pre-curing furnace for...

Embodiment 2

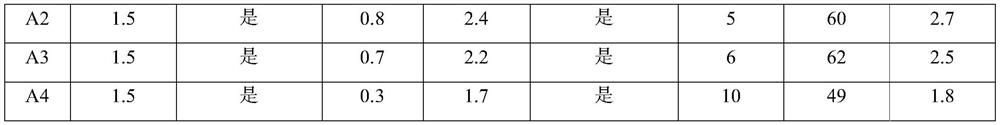

[0082] The flexible composite glass A2 was prepared by the same method as in Example 1, except that the viscosity of the flexible film slurry at 24°C was 9000cps, and the viscosity of the hardened film slurry at 24°C was 6000cps. The performance tests of the prepared flexible composite glass product A2, flexible film and hardened film are carried out, and the results are listed in Table 1.

Embodiment 3

[0084] The flexible composite glass A3 was prepared by the same method as in Example 1, except that the viscosity of the flexible film slurry at 24°C was 6000cps, and the viscosity of the hardened film slurry at 24°C was 9000cps. The performance tests of the prepared flexible composite glass product A3, flexible film and hardened film are carried out, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com