Manufacturing method of PET bottom plate and mother plate combined film

A production method and technology of bonding film, applied in chemical instruments and methods, lamination auxiliary operations, lamination devices, etc., can solve problems such as high cost and waste, and achieve the effects of low cost, uniform coating and improved preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

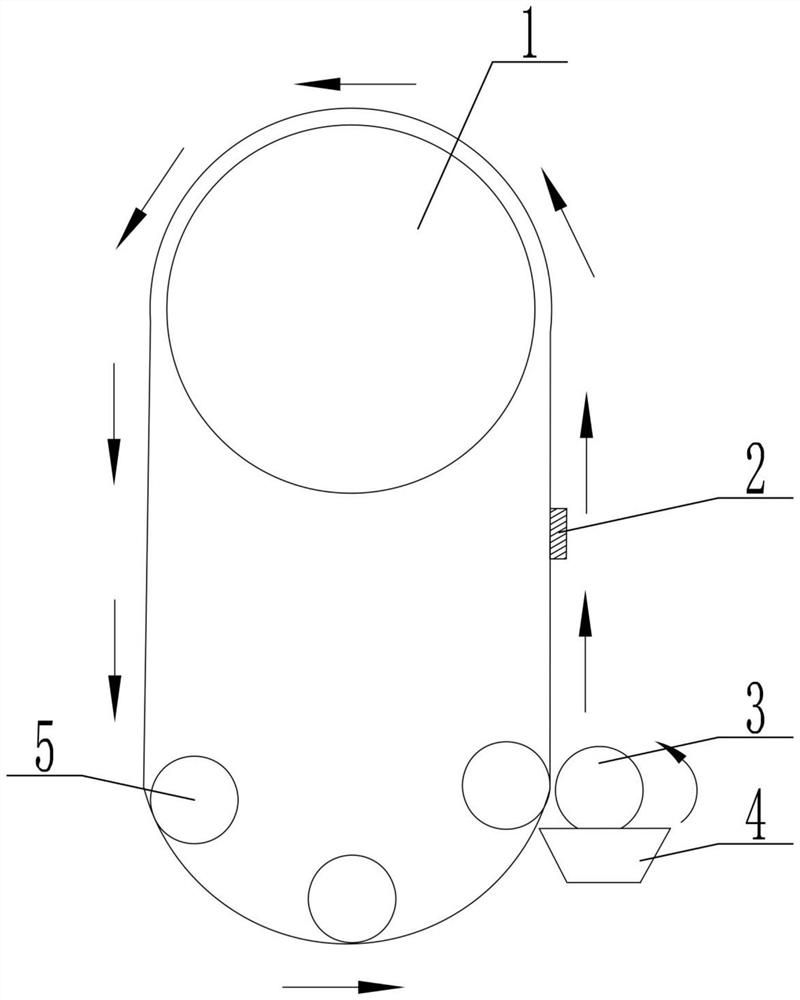

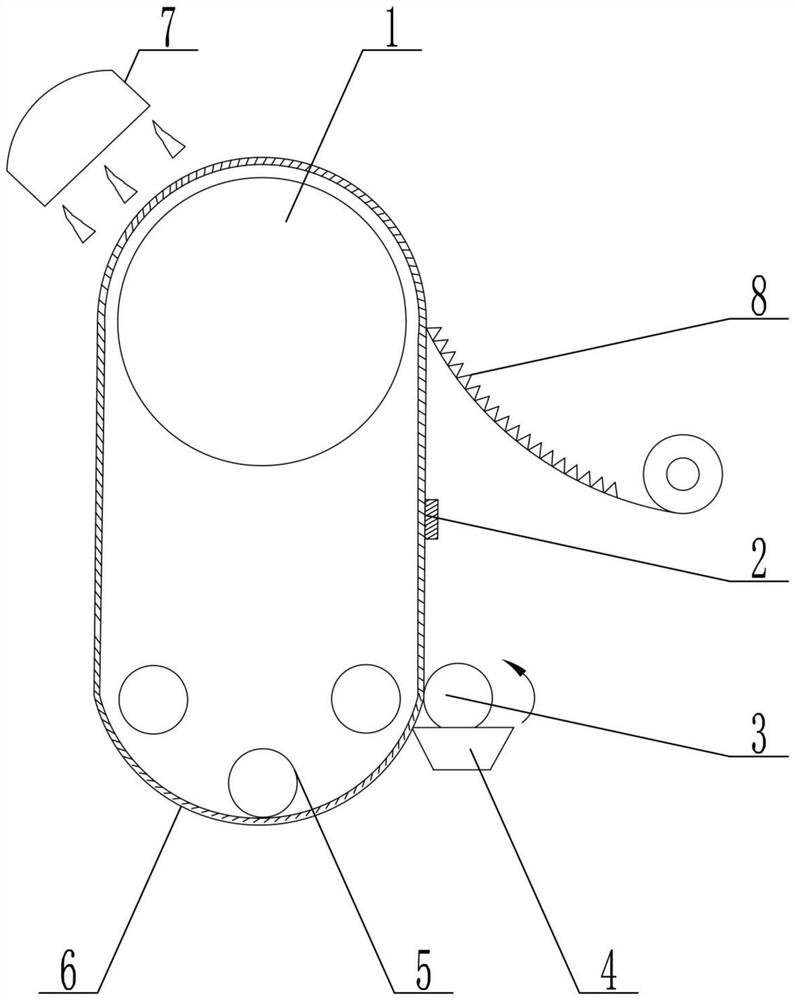

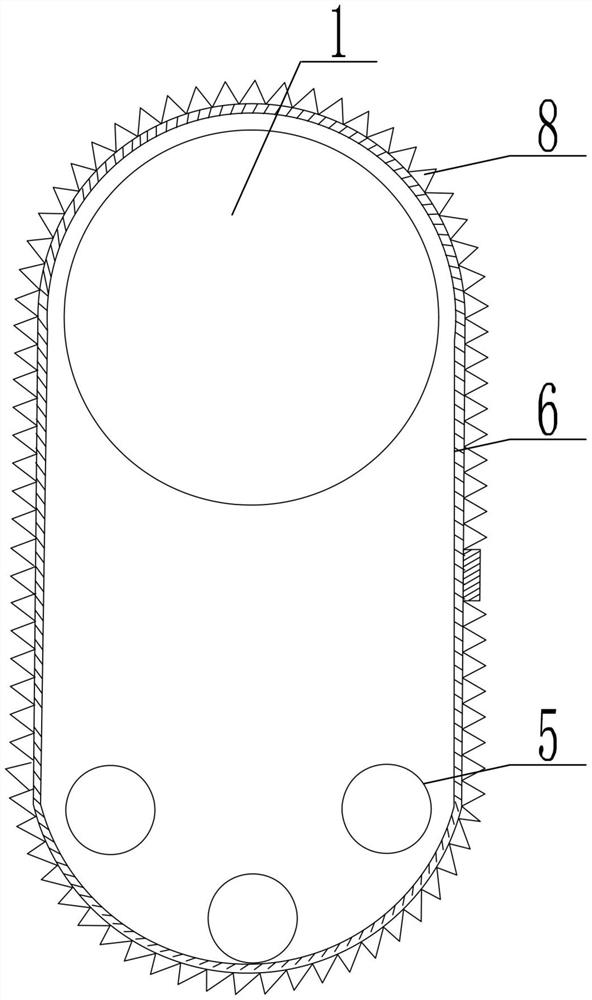

[0042]A method for making a combination film of a PET bottom plate and a mother plate, comprising a large rubber roller assembly 1, a guide roller 5, a PET bottom plate 6, and a mother plate 8, and the PET bottom plate 6 is respectively connected with the large rubber roller assembly 1, the guide roller The rollers 5 are connected, and the large rubber roller assembly 1 drives the PET bottom plate 6 to reciprocate, and also includes a splicing fixture 2, a pre-coating roller assembly 3, a liquid tank assembly 4 and an ultraviolet curing lamp 7. The splicing The fixing part 2 is adapted to the PET base plate 6 and the master plate 8 respectively, the pre-coating roller assembly 3 is adapted to the liquid tank assembly 4, and the pre-coating roller assembly 3 is matched to the PET base plate 6 Contact, the motherboard 8 is respectively adapted to the PET bottom plate 6 and the ultraviolet curing lamp 7, and its manufacturing method is as follows:

[0043] (a) Get the PET base pl...

Embodiment 2

[0058] A method for making a combination film of a PET bottom plate and a mother plate, comprising a large rubber roller assembly 1, a guide roller 5, a PET bottom plate 6, and a mother plate 8, and the PET bottom plate 6 is respectively connected with the large rubber roller assembly 1, the guide roller The rollers 5 are connected, and the large rubber roller assembly 1 drives the PET bottom plate 6 to reciprocate, and also includes a splicing fixture 2, a pre-coating roller assembly 3, a liquid tank assembly 4 and an ultraviolet curing lamp 7. The splicing The fixing part 2 is adapted to the PET base plate 6 and the master plate 8 respectively, the pre-coating roller assembly 3 is adapted to the liquid tank assembly 4, and the pre-coating roller assembly 3 is matched to the PET base plate 6 Contact, the motherboard 8 is respectively adapted to the PET bottom plate 6 and the ultraviolet curing lamp 7, and its manufacturing method is as follows:

[0059] (a) Get the PET base p...

Embodiment 3

[0074] A method for making a combination film of a PET bottom plate and a mother plate, comprising a large rubber roller assembly 1, a guide roller 5, a PET bottom plate 6, and a mother plate 8, and the PET bottom plate 6 is respectively connected with the large rubber roller assembly 1, the guide roller The rollers 5 are connected, and the large rubber roller assembly 1 drives the PET bottom plate 6 to reciprocate, and also includes a splicing fixture 2, a pre-coating roller assembly 3, a liquid tank assembly 4 and an ultraviolet curing lamp 7. The splicing The fixing part 2 is adapted to the PET base plate 6 and the master plate 8 respectively, the pre-coating roller assembly 3 is adapted to the liquid tank assembly 4, and the pre-coating roller assembly 3 is matched to the PET base plate 6 Contact, the motherboard 8 is respectively adapted to the PET bottom plate 6 and the ultraviolet curing lamp 7, and its manufacturing method is as follows:

[0075] (a) Get the PET base p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com