Box body packaging and forming device

A molding device and box body technology, applied in packaging, transportation and packaging, box making operations, etc., can solve the problems of troublesome equipment operation and control, limited number of processes, large input cost, etc., and achieve productivity with easy automation, powerful functions, High productivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

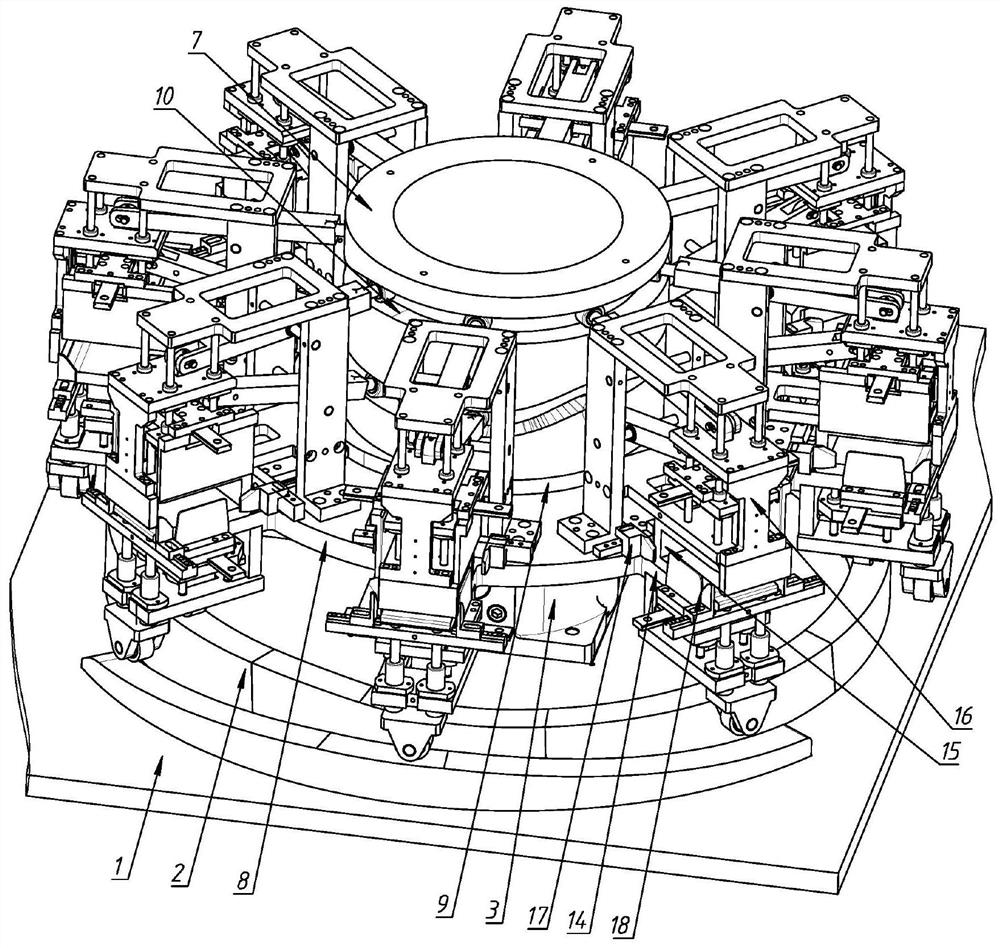

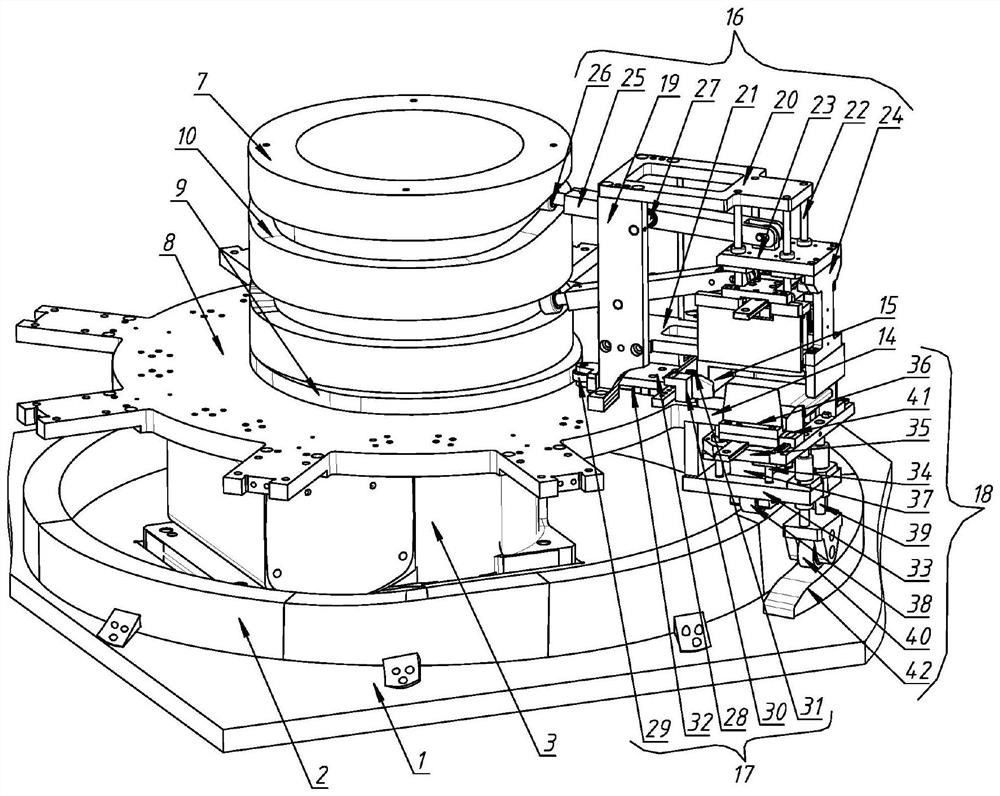

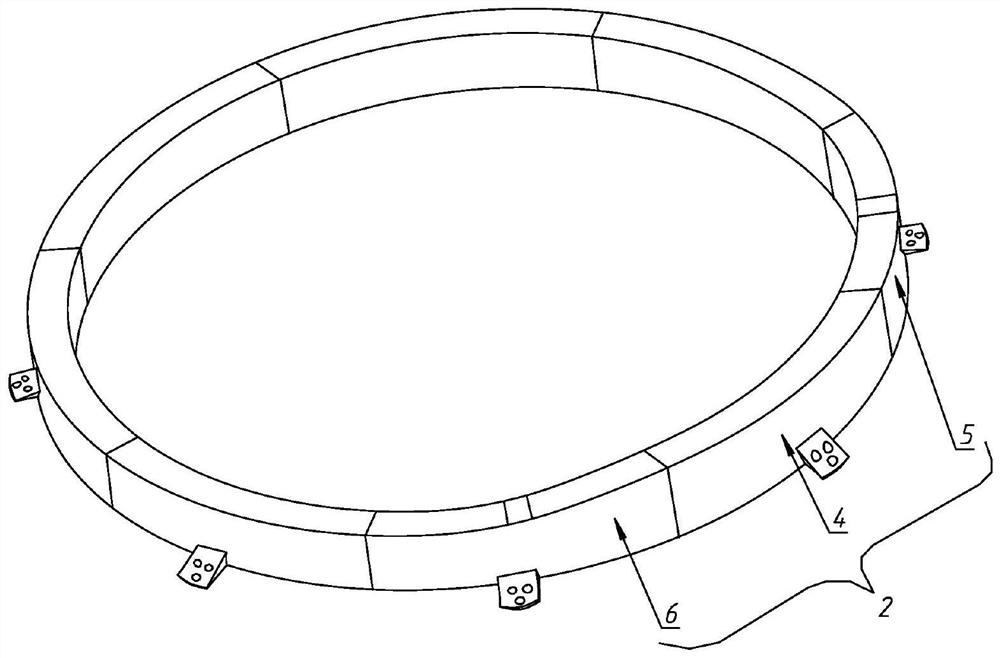

[0030]Such asFigure 1-8As shown, the present invention provides a casing package molding apparatus, including a table 1, a top fixed-to-ring rail projection 2 and a support driving device 3, and the annular rail projection 2 is a splicing structure, and the annular rail projection is protruded. 2 includes a holding guide rail 4, a release guide rail 5, and a transition guide rail 6, and the top end plane of the holding guide rail 4 is higher than the release guide rail 5, and the top portion of the support driving device 3 is provided with a center cylinder 7 and the turntable 8, and the output of the supporting device 3 is output. The shaft is fixed to the rotary table 8, and the support of the supporting device 3 is fixed to the center cylinder 7, and the bottom end of the center cylinder 7 is fixed, and the side surface of the center cylinder 7 is provided on the side surface of the center cylinder 7, and the annular rail groove 10 is provided. The side plane includes a holding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com