Castanea mollissima opening machine for nut food processing

A technology for food processing and nuts, applied in the field of chestnut opener, which can solve the problems of easily damaged pulp, achieve good opening effect, reduce labor intensity, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

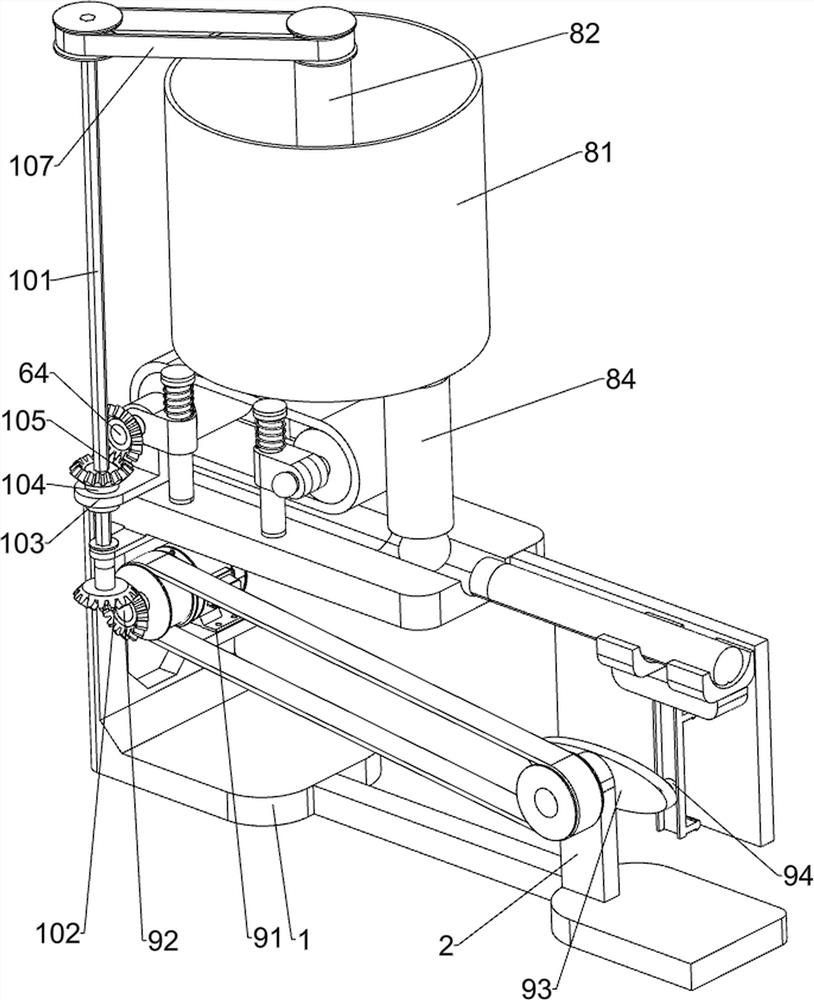

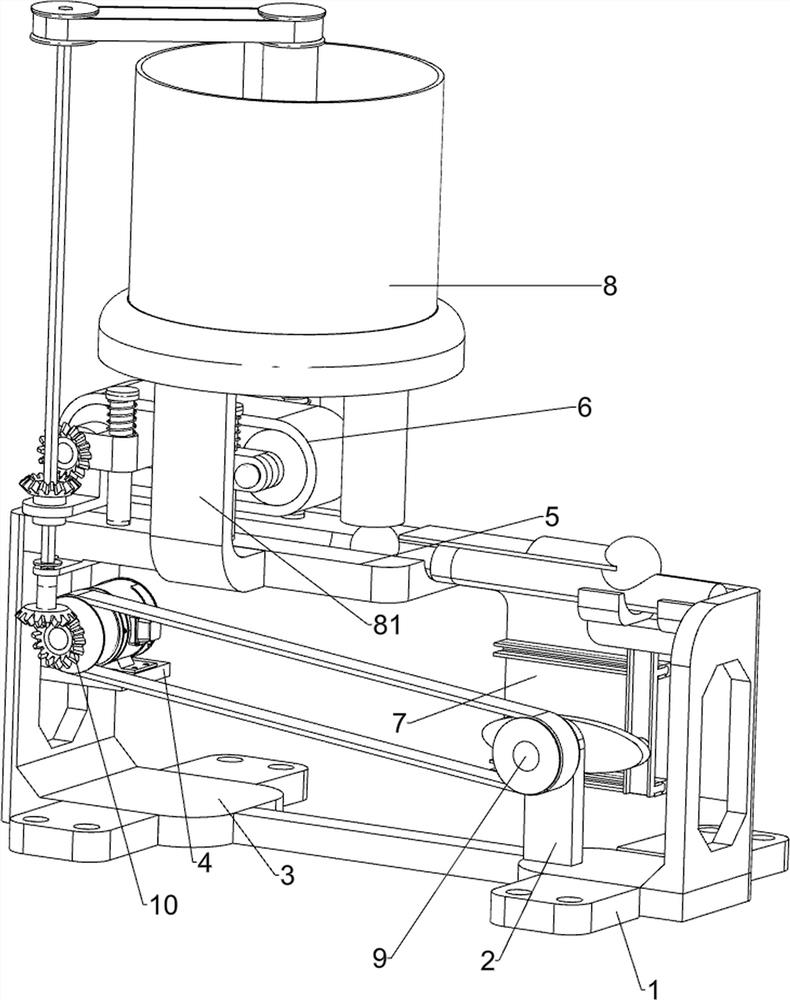

[0027]A chestnut opening machine for nut food processing, such asFigure 1-2 As shown, including the first base 1, the first mounting plate 2, the second base 3, the second mounting plate 4, the opening device 5, the extrusion device 6 and the pusher 7, and the first base 1 is connected to the first connection. The mounting plate 2, the first base 1 is connected to the left side, and the middle portion of the second base 3 is attached, and the opening device 5 is attached to the second base 3, and an extrusion is connected to the opening device 5. The device 6 is connected to the first base 1.

[0028]The opening device 5 includes a pass groove plate 51 and a blade 52, and the top of the second base 3 is connected to the tank plate 51, and the middle portion of the passage plate 51 is connected to the blade 52.

[0029]The extrusion device 6 includes a guide bar 61, a slide jaw 62, a reset spring 63, a pulley 64, and a flat belt 65. The front and rear sides of the top of the pass groove 51...

Embodiment 2

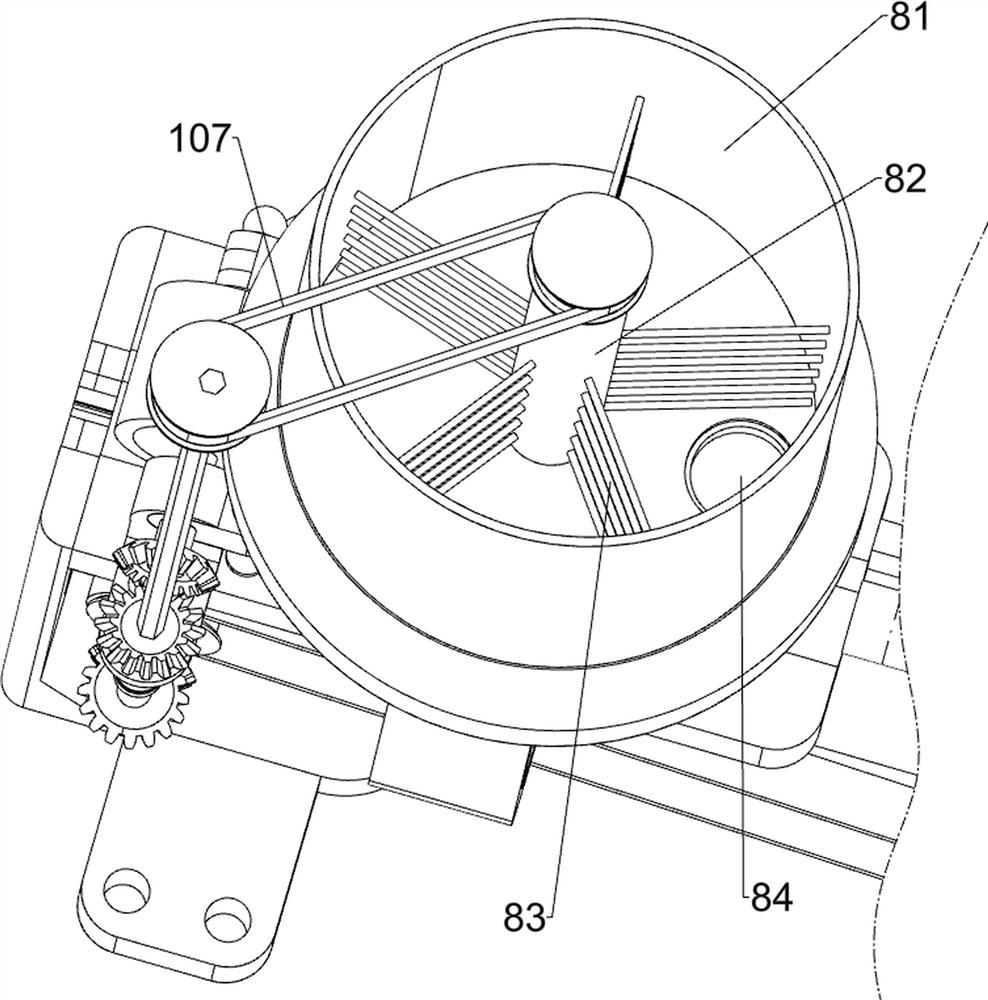

[0033]On the basis of Example 1, such asFigure 3-4As shown, it is also included, and the discharge device 8 includes a storage barrel 81, a shaft 82, a stirring lever 83, and a tube 84, and a tank plate 51 is connected to the top of the tank 81, a stock. The shaft 82 is rotatably connected in the cartridge 81, and the shaft 83 is uniformly connected to the shaft 82, and the discharge tube 84 is connected at the bottom of the storage tube 81, and the bottom end of the discharge tube 84 is in contact with the blocking plate 75. .

[0034]The chestnut is poured into the reservoir 81, and the chestnut falls within the groove of the passage plate 51 by the discharge tube 84, and when the blocking plate 75 moves to the left, the blocking plate 75 blocks the bottom of the pipe 84, And the blocking plate 75 pushes the chestnut to the left. When the blocking plate 75 is reset to the right, the blocking plate 75 is removed from the bottom of the discharge tube 84, and the bottom tube 84 can drop...

Embodiment 3

[0038]On the basis of Example 2, such asFigure 4 As shown, there is a transmission device 10, and the transmission device 10 includes a rhombus rod 101, a first cone gear 102, a connection block 103, an internal firing sleeve 104, a second cone 105, and a belt drive group 106, and a pass groove plate 51 The left end rotation of the front side is connected to the rhombic rod 101, and the front end of the rhombic rod 101 and the front end of the rotating shaft 92 are connected to the first cone gear 102, two first cone 102 mesh, the left side of the front side 62 The connection block 103 is connected to the connecting block 103, and the insertion block 103 is embedded, and the inner rod 104 is rotatable, the diametric rod 101 runs through the center of the inner life sleeve 104, the inner rod sleeve 104 and the diamond rod 101 Sliding fit, the front end of the left belt wheel 64 is connected to the end of the inner hem, and the two second cone 105 each other, the top end of the diamon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com