Hard carbon negative electrode material

A negative electrode material, hard carbon technology, applied in the direction of negative electrode, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problems of degradation, safety and life and other important performance without much improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

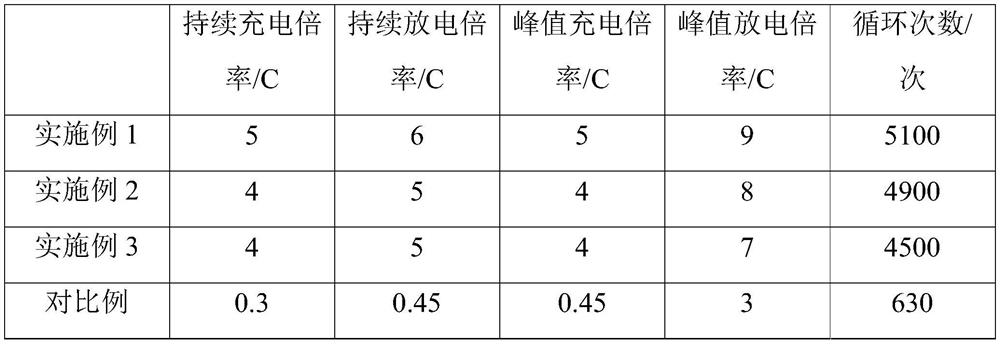

Examples

preparation example Construction

[0028] The preparation method of the hard carbon negative electrode material comprises the following steps:

[0029] Pretreatment: weighing the raw material according to the negative electrode material described in claim 1, dissolving the carbon source in water, putting it into the first container, and putting vanadium pentoxide into the second container;

[0030] Mixing heat with oil and water: Add deionized water to the first container and the second container respectively, then add vegetable oil dropwise, put the first container and the second container in a closed device, heat and keep warm, and then put the solution in the first container Pour into the second container, add boron powder, continue to heat up and keep warm, cool naturally after the reaction is complete, filter and dry to obtain a semi-finished negative electrode material;

[0031] Post-processing: The chemical vapor deposition method is used to deposit fillers on the surface of the semi-finished negative el...

Embodiment 1

[0039] Weigh raw materials according to the above-mentioned hard carbon negative electrode material, including the following components in parts by weight: 60 parts of vanadium pentoxide, 8 parts of carbon source, 5 parts of boron powder, 1 part of filler, wherein the carbon source is glucose, and the filler is For tin nitride, the carbon source is dissolved in water, packed into the first container, and vanadium pentoxide is packed into the second container;

[0040] Mixing oil and water: Add 1 part of deionized water to the first container and the second container respectively, then add 1 part of the mixed oil of peanut oil, linseed oil and castor oil dropwise, and put the first container and the second container in a closed device , heated to 130°C and kept warm for 65s, then poured the solution in the first container into the second container, added boron powder, continued to heat up to 260°C and kept warm for 1.5h, cooled naturally after the reaction was complete, and filt...

Embodiment 2

[0044]Weigh the raw material according to the above hard carbon negative electrode material, including the following components in parts by weight: 68 parts of vanadium pentoxide, 10 parts of carbon source, 6 parts of boron powder, 3 parts of filler, wherein the carbon source is sucrose, and the filler is For silicon nitride, the carbon source is dissolved in water, packed into the first container, and vanadium pentoxide is packed into the second container;

[0045] Mixing oil and water: Add 1 part of deionized water to the first container and the second container respectively, then add 1 part of the mixed oil of peanut oil, linseed oil and castor oil dropwise, and put the first container and the second container in a closed device , heated to 140°C and kept warm for 70s, then poured the solution in the first container into the second container, added boron powder, continued to heat up to 270°C and kept warm for 1.6h, cooled naturally after the reaction was complete, and filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com