Waterproof shield segment

A shield segment, waterproof technology, applied in wellbore lining, tunnel lining, underground chambers, etc., can solve the problems of clogging of water filtering equipment, poor guiding and diverting ability, and reducing water filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

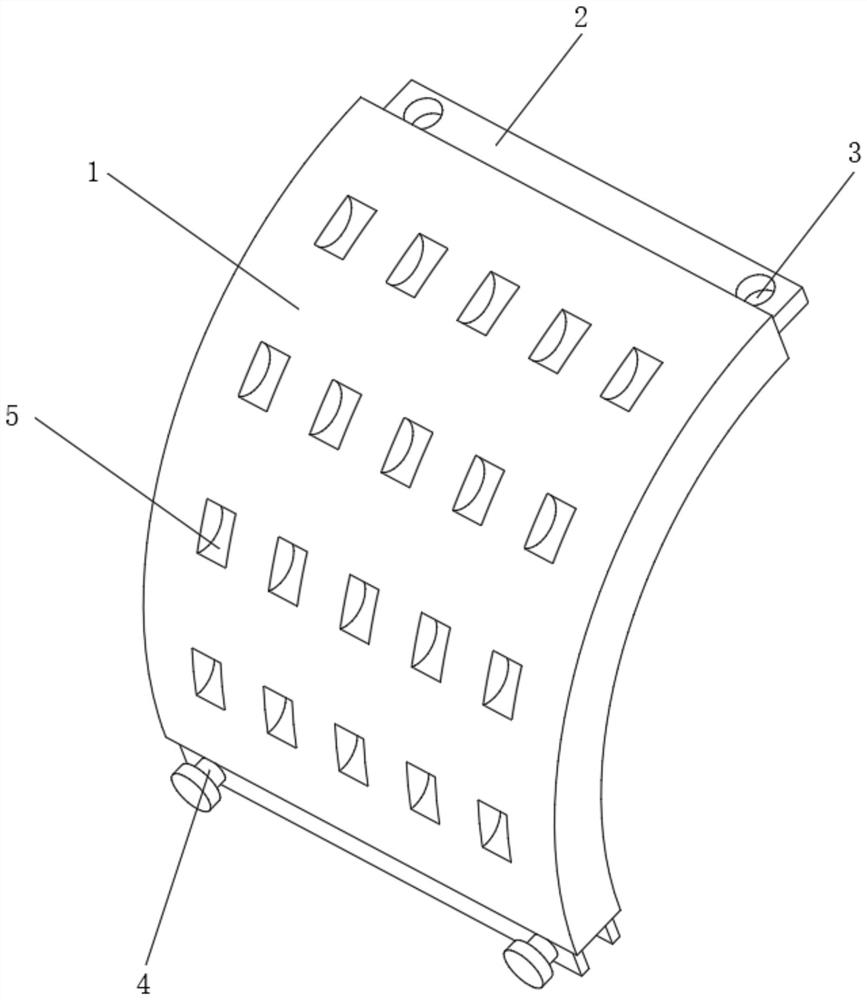

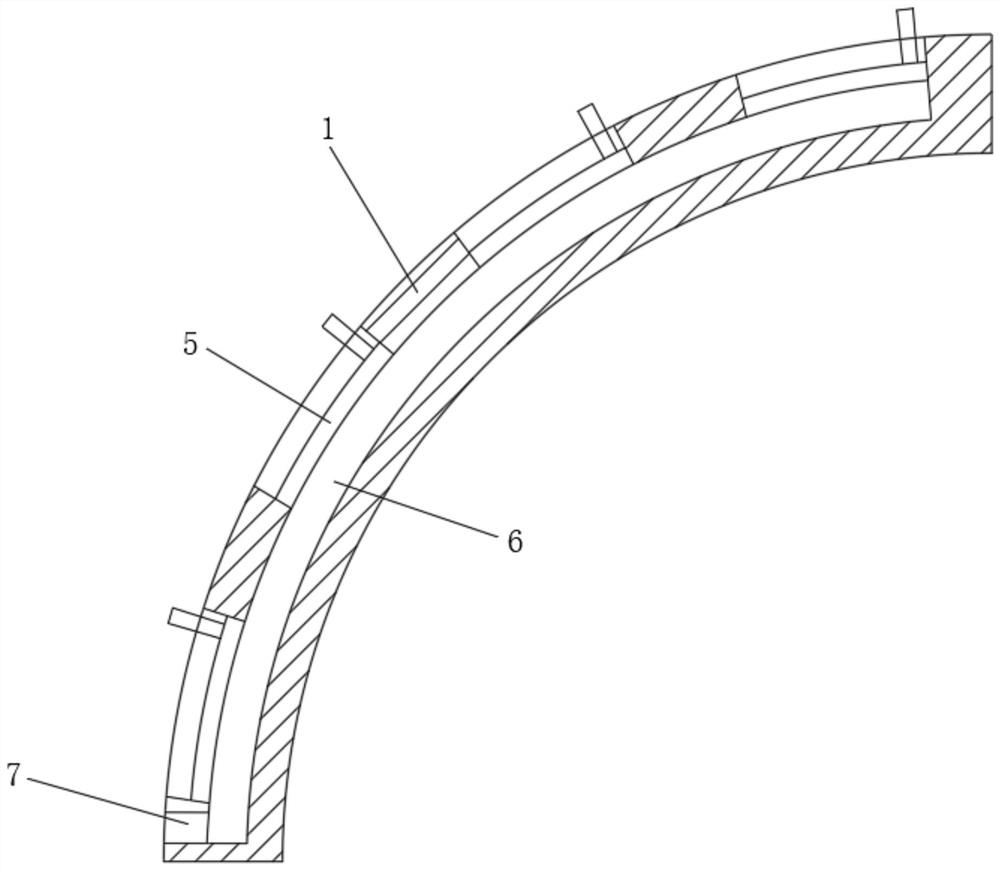

[0037] Such as Figure 1-3 As shown, the present invention provides a technical solution: a waterproof shield segment, including a segment body 1, the top of the segment body 1 is fixedly connected with an assembly clamp 2, and both ends of the surface of the assembly clamp 2 are provided There are installation through holes 3, the left and right sides of the bottom of the segment main body 1 are provided with mounting bolts 4, the inside of the segment main body 1 and the surface close to the outside are provided with a water diversion separation mechanism 5, and the middle position inside the segment main body 1 is provided with an inner Conduction through pipe 6, drain conduit 7 is arranged on the outer side of segment main body 1 close to the bottom, and the output end at the bottom of inner conduction through pipe 6 communicates with drain conduit 7;

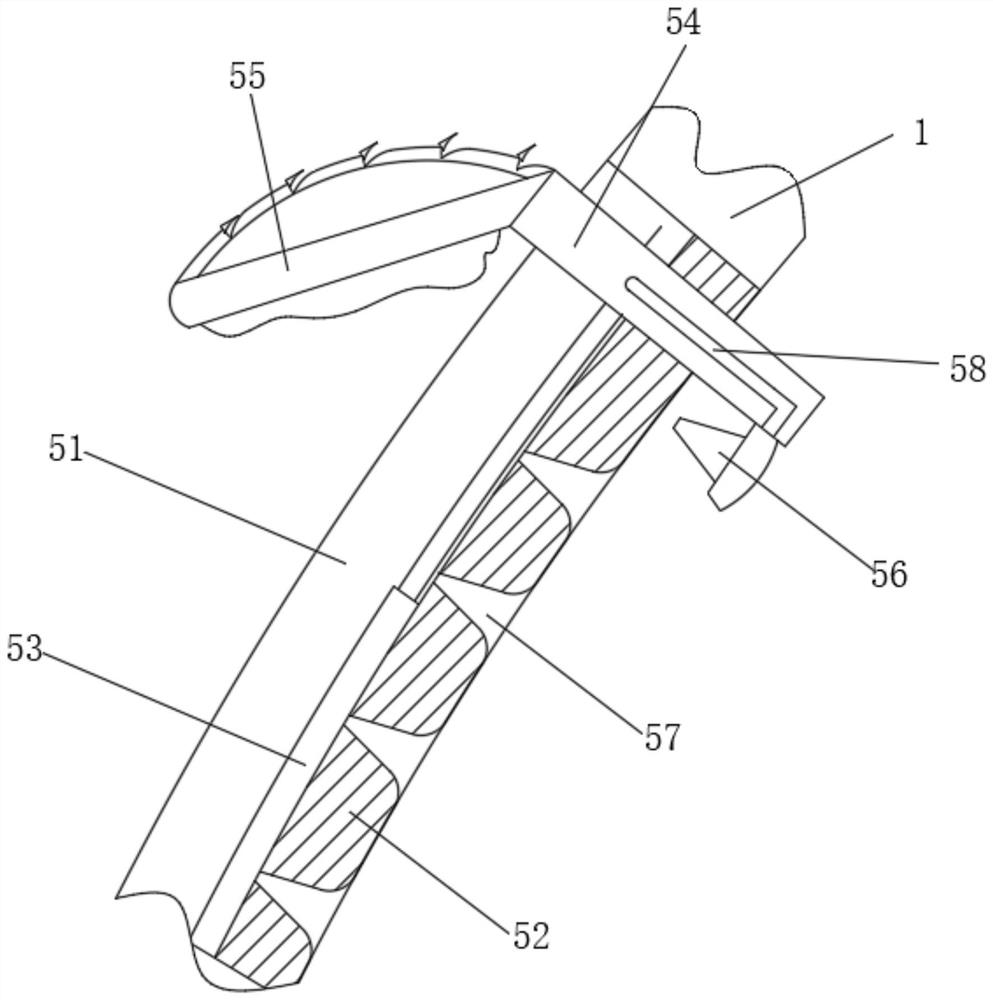

[0038] The water diversion separation mechanism 5 includes a liquid guide channel 51, a filter sieve plate 52 is fixedly ...

Embodiment 2

[0041] Such as Figure 4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a waterproof shield segment, the compression protection assembly 55 includes an adjustment pressure plate 551, and the right side of the adjustment pressure plate 551 is fixed to the propulsion guide rod 54 Connected, the top end of the outside of the adjustment pressure plate 551 is fixedly connected with a pasted caplet 552 .

[0042] A blocking air bag 553 is fixedly connected to the surface of the bottom of the adjusting pressure plate 551 , and a swinging protrusion 554 is evenly and fixedly connected to the surface of the attached capsule sheet 552 . Provide support for the soil outside the shield segment, and protect the soil outside the shield segment from a large amount of loss.

Embodiment 3

[0044] Such as Figure 5-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a waterproof shield segment, the movable dredging component 56 includes a filling plug 561, and the bottom of the filling plug 561 is connected with the propelling The guide rod 54 is fixedly connected, and a cleaning nozzle 562 is arranged in the middle of the filling plug 561 , and the cleaning nozzle 562 communicates with the air duct 58 .

[0045] A restricting roller head 563 is fixedly connected to the middle position outside the filler plug 561 , and a traveling protrusion 564 is fixedly connected to the bottom surface of the restricting roller head 563 . It can loosen the stored fixed particles, reduce the resistance during cleaning and improve the dredging effect.

[0046] Shaking cams 565 are evenly and fixedly connected to the outer surface of the limiting roller head 563 , and cleaning pushers 566 are fixedly connected to both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com