Preparation method of biodegradable cool fabric

A cool-feeling fabric and biological technology, applied in fabric surface trimming, textile material treatment, dyeing, etc., can solve problems such as poor wearing comfort and stuffy fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

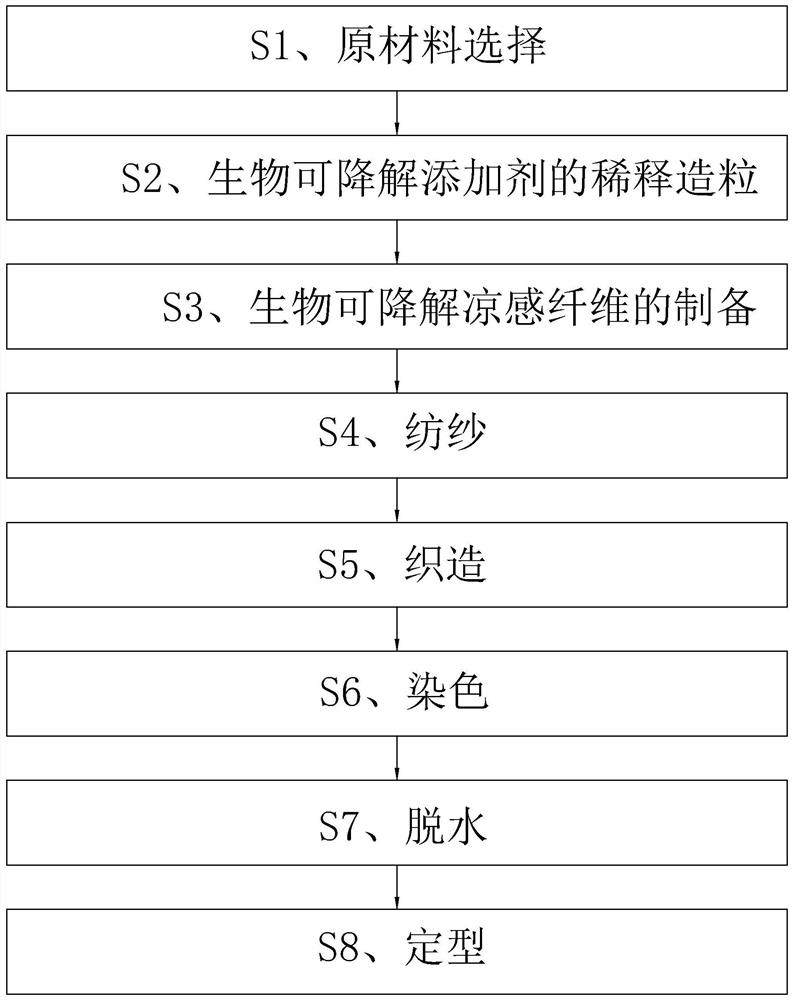

[0021] Embodiment 1: a kind of preparation method of biodegradable cool feeling fabric, such as figure 1 shown, including the following steps:

[0022] S1. Raw material selection:

[0023] The base material is made of polyester chips, the biodegradable additive is made of EcoPure PET (G2), and the cooling agent is made of jade powder.

[0024] S2. Dilute granulation of biodegradable additives:

[0025] The biodegradable additive and the polyester chip are mixed evenly in the drum according to the mass ratio of 1:5, and then granulated by a twin-screw granulator to obtain the diluted biodegradable additive masterbatch.

[0026] S3, the preparation of biodegradable cooling fiber, comprising the following steps:

[0027] The first process step: the base material, the diluted biodegradable additive masterbatch and the cooling additive are mixed uniformly in a drum by vacuum heating and drying at a mass ratio of 90:5:5.

[0028] The second step: the dried mixture is melted and ...

Embodiment 2

[0044] Embodiment 2: a kind of preparation method of biodegradable cool feeling fabric, and the step different from embodiment 1 is:

[0045] S5. Weaving:

[0046] Equipment: Meyer West single-sided machine with 34 inches and 28G stitches.

[0047] Fabric Weave: Single Piqué.

[0048] Yarn length: 26.5cm / 100N.

[0049] S6, dyeing, comprises the following steps:

[0050] 1. Pre-treatment process: add degreasing agent and refining agent at room temperature, raise the temperature to 98°C at a rate of 2°C / min, keep warm for 30 minutes, cool down to 75°C at a rate of 2°C / min, drain water, and then wash with water for 2 times, washed with glacial acetic acid once;

[0051]2. Dyeing process: Add leveling agent and glacial acetic acid at 40°C, adjust the pH value to 3.7-4.2, add dye, heat up to 90°C at a rate of 2-3°C / min, and then increase the temperature at a rate of 1°C / min Keep warm at 130°C for 35 minutes, then cool down to 70°C at a rate of 2°C / min to take samples.

[0052...

Embodiment 3

[0057] Embodiment 3: a kind of preparation method of biodegradable cool feeling fabric, and the step different from embodiment 1 is:

[0058] S5. Weaving:

[0059] Equipment: Meyer West single-sided machine with 34 inches and 28G stitches.

[0060] Fabric Weave: Single Piqué.

[0061] Yarn length: 26.5cm / 100N.

[0062] S6, dyeing, comprises the following steps:

[0063] 1. Pre-treatment process: add degreasing agent and refining agent at room temperature, raise the temperature to 98°C at a rate of 2°C / min, keep warm for 30 minutes, cool down to 75°C at a rate of 2°C / min, drain water, and then wash with water for 2 times, washed with glacial acetic acid once;

[0064] 2. Dyeing process: Add leveling agent and glacial acetic acid at 40°C, adjust the pH value to 3.7-4.2, add dyes, raise the temperature to 90°C at a rate of 2-3°C / min, and then increase the temperature at a rate of 1°C / min Keep warm at 130°C for 40 minutes, then cool down to 70°C at a rate of 2°C / min to take s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com