Composite fiber of polyethylene lactide and polycaprolactone, its preparation method, use and surgical suture

A technology of polylactide and polycaprolactone, which is applied in the direction of surgery, fiber treatment, conjugated synthetic polymer artificial filament, etc., can solve the problems of restricting wide application and expensive microscopic price of polylactide , to achieve the effect of good hand feeling and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

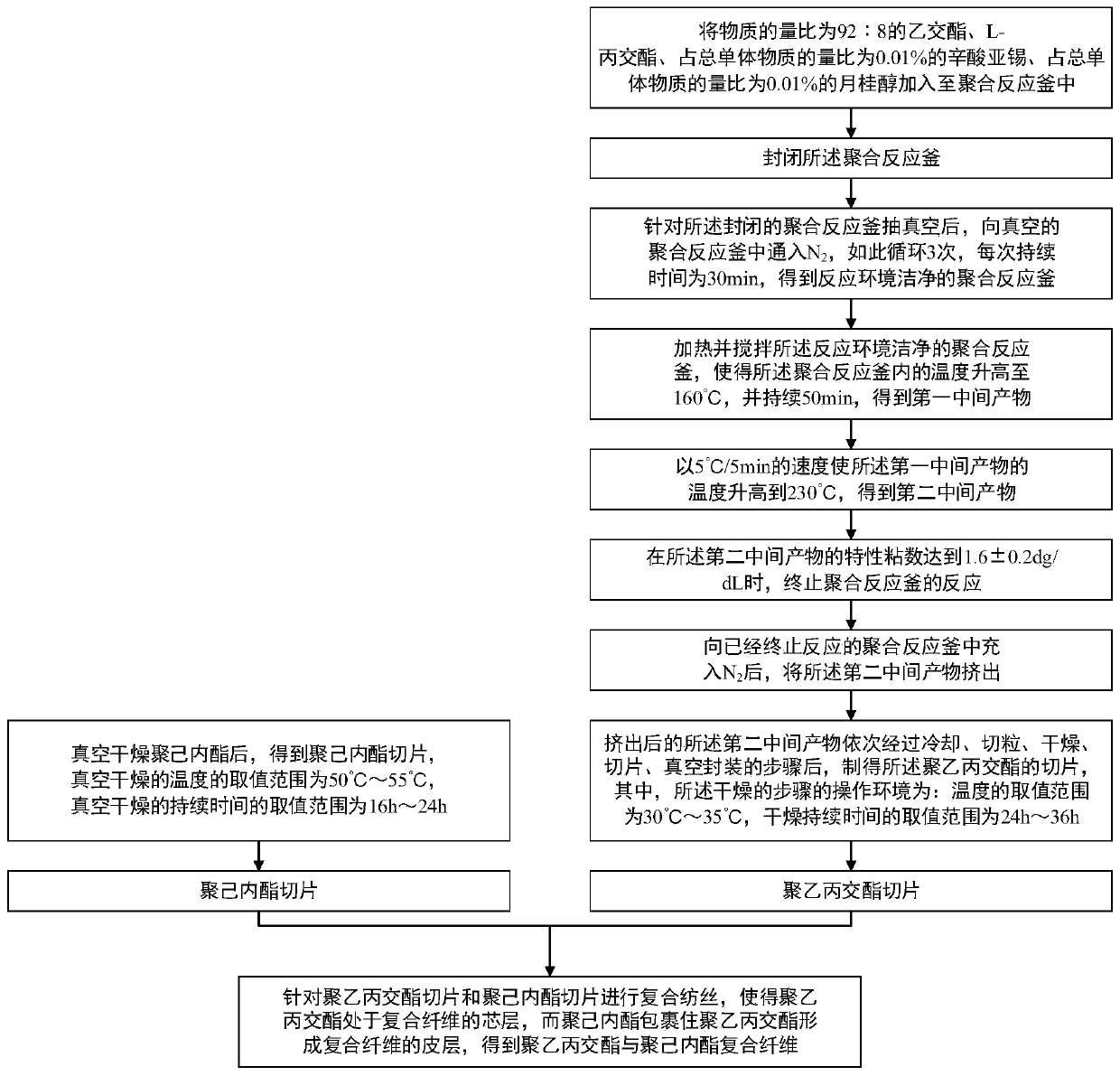

[0058] See attached figure 2 , the preparation method of polyethylene lactide and polycaprolactone composite fiber provided by the invention comprises the following steps:

[0059] Step 1: Obtain slices of polyethylene lactide and slices of polycaprolactone respectively;

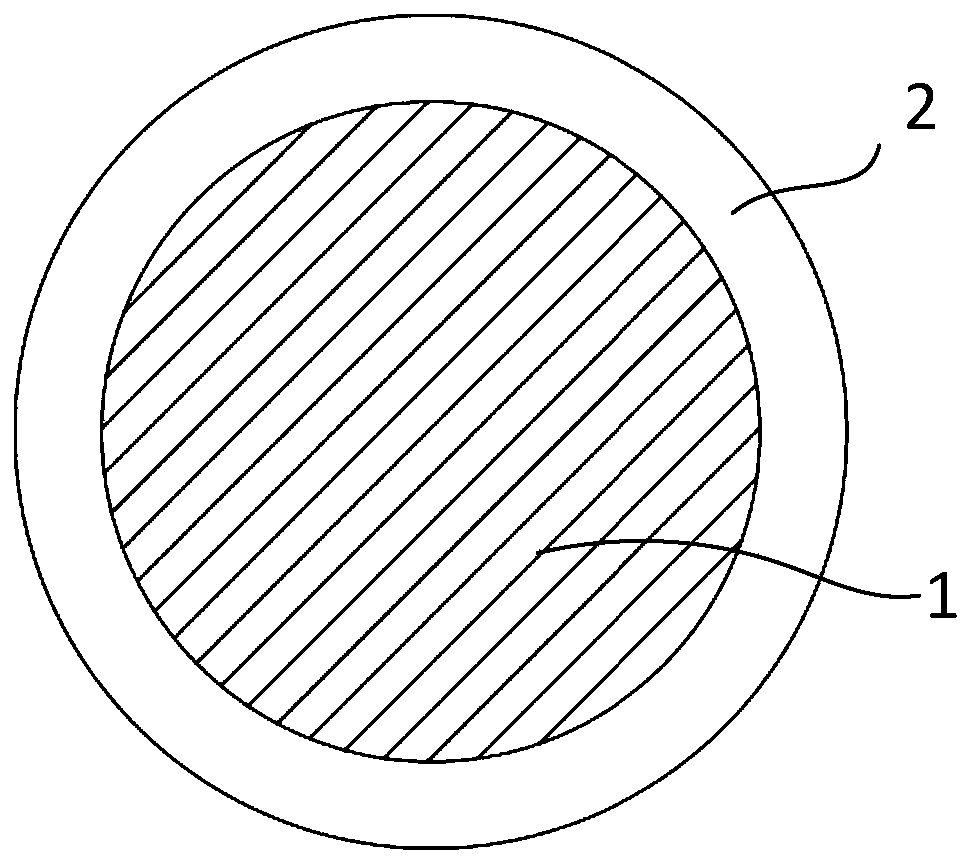

[0060] Step 2: Carry out composite spinning for polylactide slices and polycaprolactone slices, so that polylactide is in the core layer of the composite fiber, and polycaprolactone wraps polylactide to form the core layer of the composite fiber Cortex, obtain polyethylene lactide and polycaprolactone composite fiber.

[0061] Among them, the process of composite spinning for polyethylene lactide chips and polycaprolactone chips includes:

[0062] Vacuum drying is carried out under the condition of 80° C. to 100° C., and the vacuum degree of vacuum drying ranges from -0.08 MPa to 0.09 MPa.

[0063] Wherein, in step 1, the method for obtaining polycaprolactone slices comprises the following steps:

[006...

Embodiment 1

[0093] The cross-sectional area ratio of the skin layer to the core layer (with PGLA as the core of the composite fiber and PCL as the skin of the composite fiber) is 20:80, and the spare PGLA / PCL are vacuum-dried separately at a drying temperature of 80°C. Vacuum degree-0.09MPa. The composite fiber described adopts spinning-stretching one-step method, and the draw ratio is 5 times. The monofilament fineness is 2.2dtex (50D / 24f). The spinning process conditions are: the temperature range of the core layer component is 220-240°C, the screw pressure is 9.8MPa, the spinning speed is 240m / min, the temperature range of the skin layer component is 150-180°C, the screw pressure is 8.0MPa, the spinning The yarn speed is 240m / min, air cooling, and the side blowing rate is 3m / min, and the PGLA / PCL composite fiber can be obtained.

[0094] The performance parameters of PGLA / PCL composite fiber are: the tensile strength reaches 4.5CN / dtex, the elongation at break is 27%, the hand feeling...

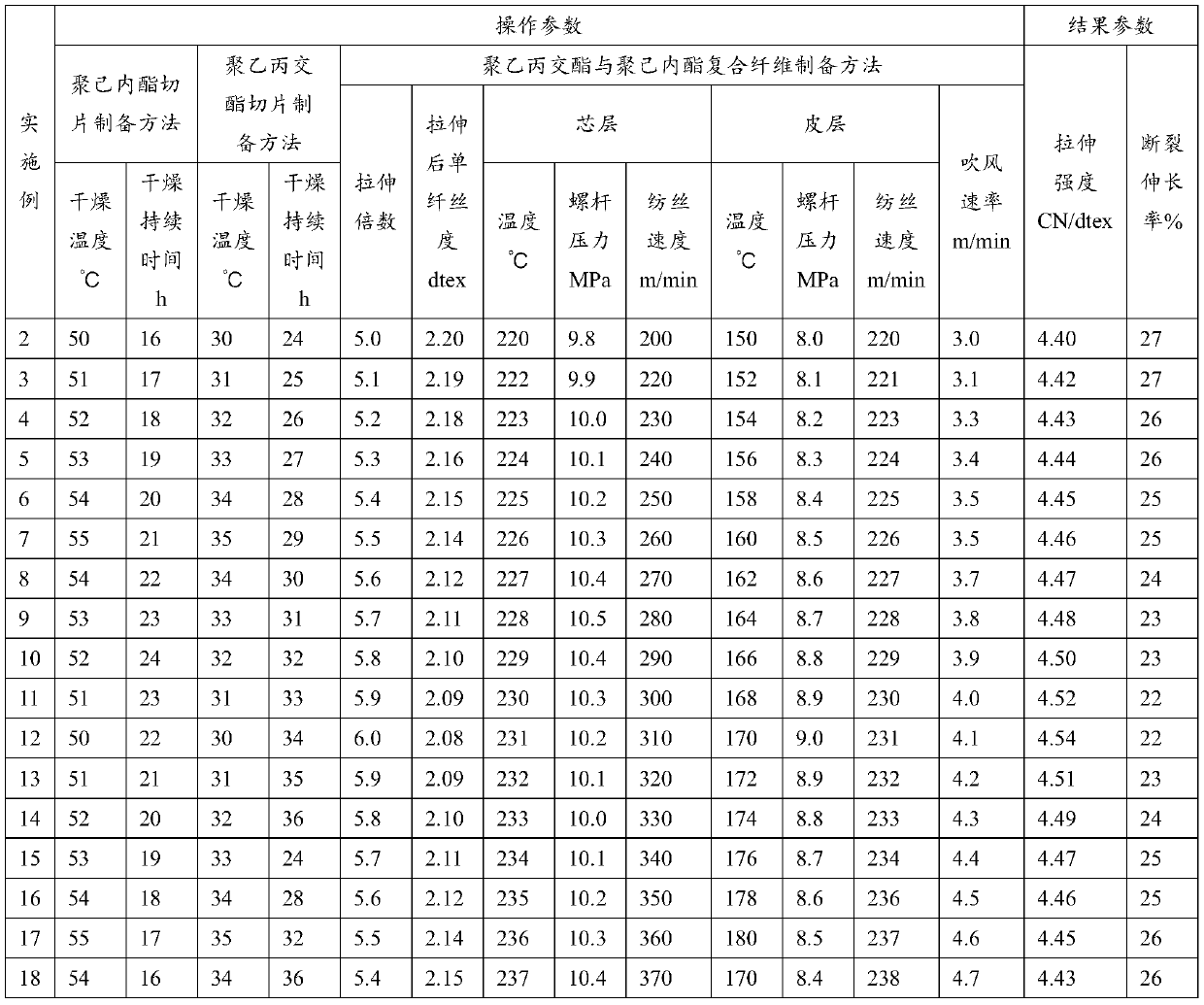

Embodiment 2~20

[0096]

[0097]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com