Sewage suction device capable of automatically winding and unwinding pipeline

A suction device, automatic retractable technology, applied in the pipeline for emptying/ballasting, transportation and packaging, machine/engine, etc. problems, to achieve the effect of high degree of automation, high security and reliability, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

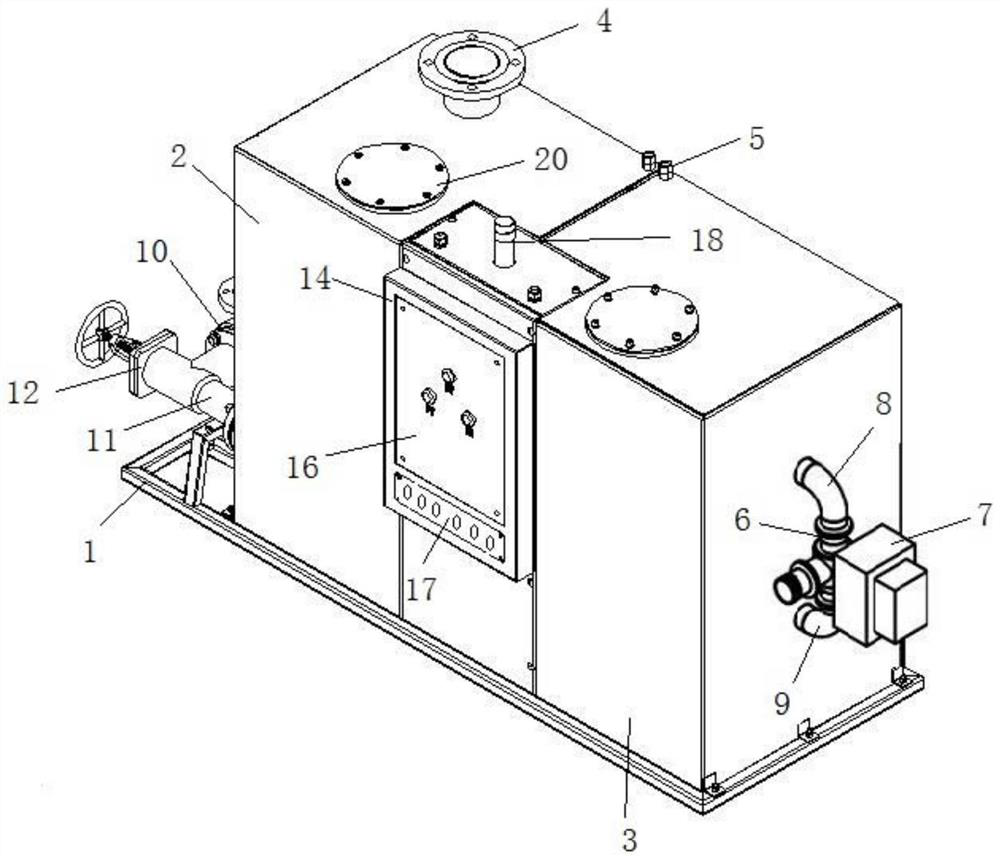

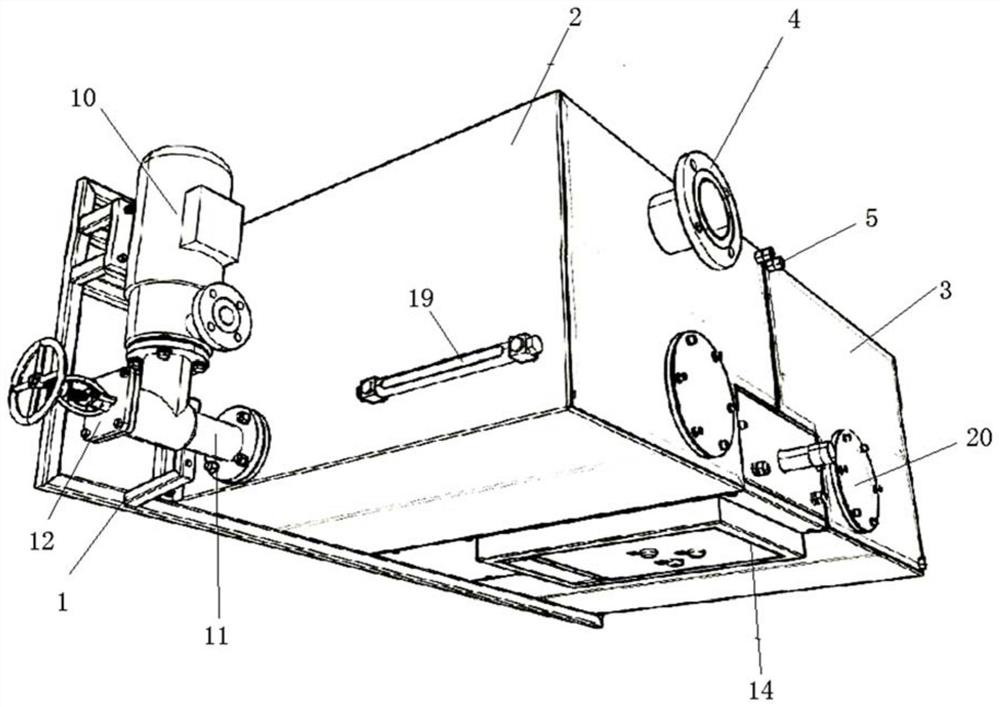

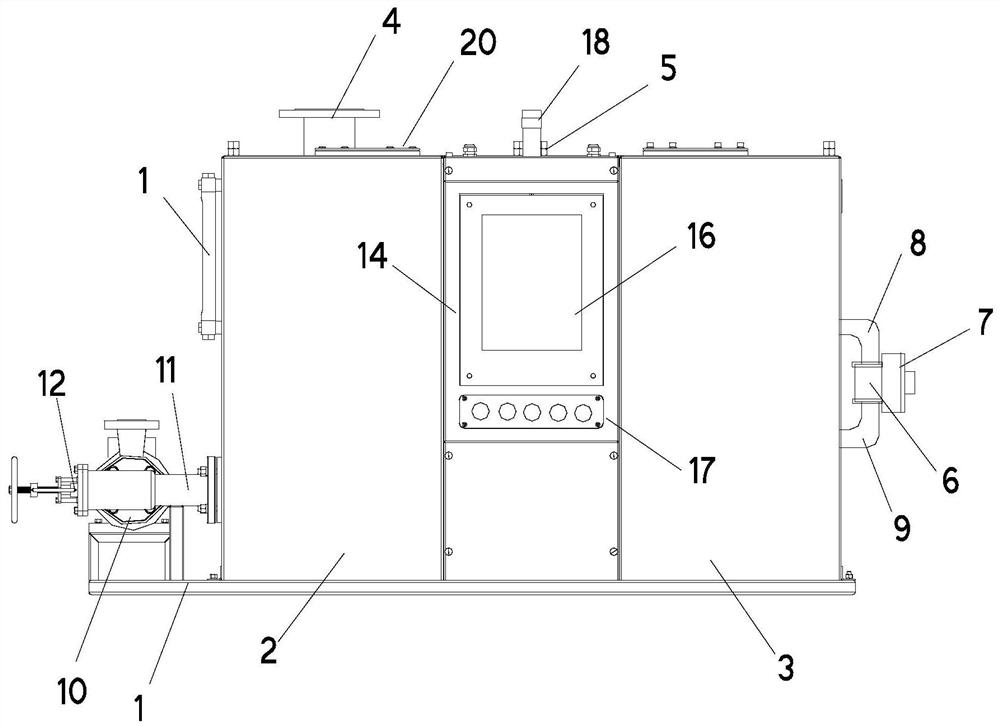

[0044] This embodiment provides a ship sewage storage device, such as Figure 1 ~ Figure 3 As shown, the sewage storage device includes a mounting frame 1, a first box body 2, a second box body 3, a liquid level gauge 19, a pulverizing circulation pump 6, an internal circulation pipeline, a cutting sewage pump 10, a sewage pipeline, and a first shut-off valve 12. The second stop valve 13 and the third stop valve 24.

[0045] In this example, a water inlet 4 and an air hole 5 are provided on the top of the first box body 2 . The water inlet 4 is used to communicate with the sewage pipe network on the ship and the inner cavity of the first box body 2. The air hole 5 is used to balance the air pressure in the first box body 2 and the second box body 3. When the first box body 2 and the second box body 3 receive sewage, the gas in the inner cavity is discharged along the air hole 5. When the first box body 2 and the second box 3 are blowing down, outside air enters along the air...

Embodiment 2

[0068] This embodiment provides a shore-based sewage suction device, such as Figure 5 As shown, the device includes a housing 61 , a hose 62 , a retractable reel, a drive mechanism for the retractable pipe, a self-priming pump 39 , a flow meter 55 , and a fourth cut-off valve 40 .

[0069] The inside of the housing 61 is provided with a supporting mechanism; the hose 62 is used to connect the sewage pipeline of the sewage storage device in the ship; the front end of the hose 62 is provided with a quick connector 63 connected to the end of the sewage pipeline.

[0070] Such as Figure 6 and Figure 7 As shown, the take-up reel includes a drum 31, a left baffle 32, a right baffle 33 and connecting bearings. The drum 31 contains an inner cavity, and one end of the drum 31 is sealed; the left baffle 32 and the right baffle 33 are sleeved on the outer wall of the drum 31, and the outside of the drum 31 between the left baffle 32 and the right baffle 33 is soft. The winding area...

Embodiment 3

[0092] Such as Figure 11 As shown, a kind of automatic control method of ship sewage storage device is provided in this example, and this method is applied in the ship sewage storage device described in embodiment 1; Automatic control method comprises the steps:

[0093] S1: In the initial state, the first box 2 and the second box 3 are empty, the first controller 15 in the control box controls the first shut-off valve 12 to be in the open state, the second shut-off valve 13 and the third shut-off valve 24 is in a closed state, and makes the crushing circulation pump 6 and the cutting sewage pump 10 in a shutdown state;

[0094] S2: The first controller 15 controls the opening of the second shut-off valve 13, the sewage storage device starts to collect the sewage inflowing from the sewage pipe network in the ship, and the gas analyzer 22 monitors the inside of the first box 2 and the second box 3 in real time The concentration of the gas produced by fermentation in the cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com