Composite polymer functional fiber, preparation method thereof and pressure spraying equipment for preparing composite polymer functional fiber

A nanocomposite fiber and polymer technology, applied in the field of fiber materials, can solve the problems of high energy consumption, expensive equipment and accessories, and uneven filament thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

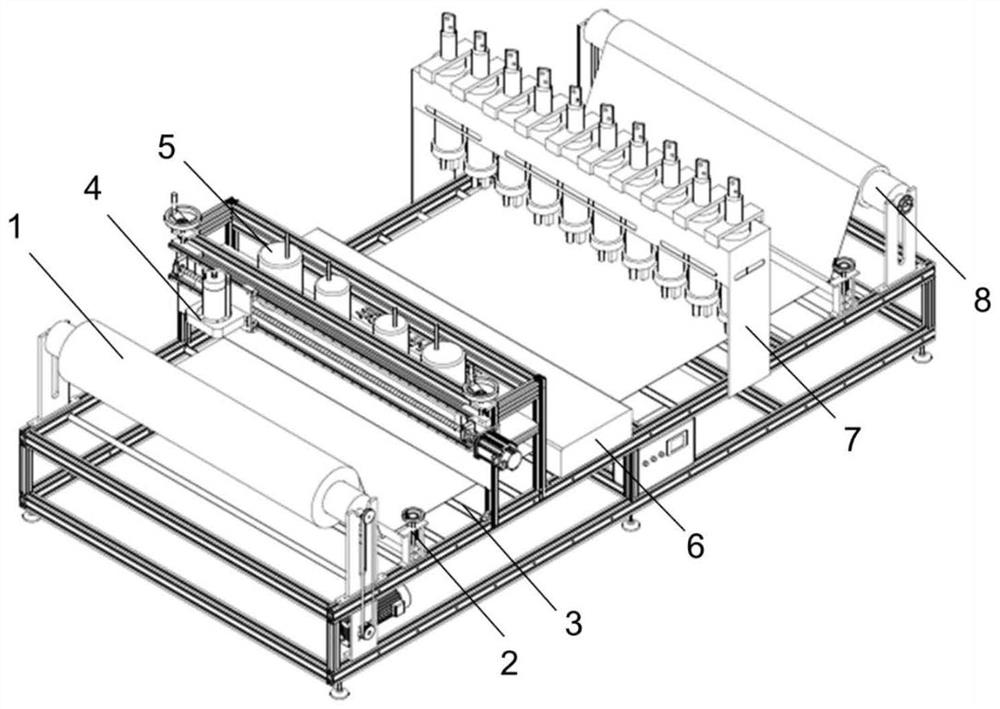

[0054] Embodiment 1 Composite polymer functionalized fiber web processing equipment

[0055] Such as figure 1 with figure 2 As shown, the composite polymer functionalized fiber web processing equipment provided in this embodiment includes sequentially arranged: gauze roller 1, manual adjustment device 2, pressure spraying device 4, sample chamber 5, drying mechanism 6, Ultrasonic point pressing mechanism 7 and take-up roller 8, and conveyor belt 3. The pressure spraying device is an automatic pressure spraying device known in the art.

[0056] The support layer is placed on the gauze roller 1, and the manual adjustment device 2 is used to adjust the transmission position and stability of the gauze. Conveying movement and winding after processing. First, it is sent to the position of the pressure spraying device 4, and the polymer nanocomposite solution contained in the sample chamber 5 is extruded and sprayed in a mist form by the pressure spraying device 4 through the se...

Embodiment 2

[0057] Polyvinylidene fluoride nanocomposite solution, supporting layer and protective layer used in embodiment 2

[0058] 1. Preparation of Polyvinylidene Fluoride Nanocomposite Solution

[0059] Dissolve the carboxyl-modified graphene oxide sheet (GO) and polyvinylidene fluoride with a molecular weight of 500,000-550,000 g / mol in N,N'-dimethylformamide, ultrasonically disperse for 4 hours, and centrifuge to collect the Serum.

[0060] Wherein, the surface carboxyl-modified graphene oxide sheet accounts for 2.0 wt% of the total mass of the polyvinylidene fluoride nanocomposite material.

[0061] 2. Selection of support layer

[0062] The supporting grid skeleton made of nylon is selected, the thickness of the supporting grid skeleton is 0.6mm, and the supporting grid cloth is 20-100 mesh nylon and glass fiber mesh cloth. In this embodiment, 20 mesh mesh cloth is selected.

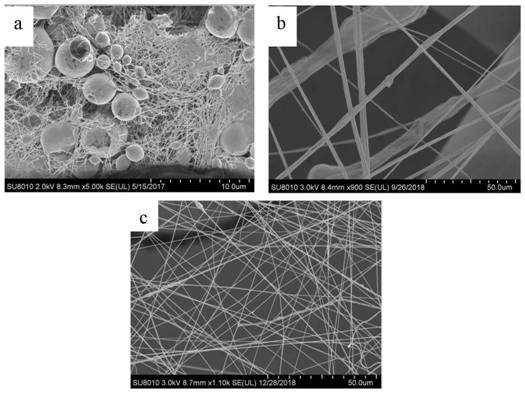

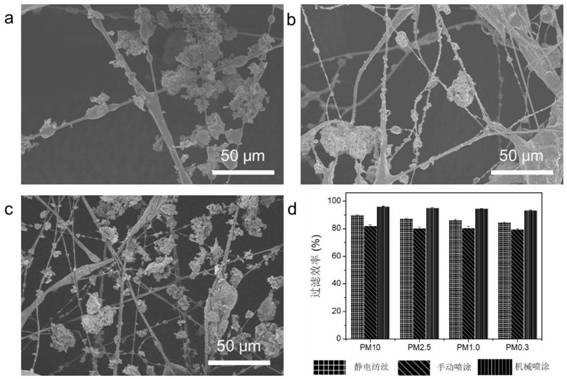

[0063] Optical and scanning electron micrographs of the support layer as Figure 4 as shown in a. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com