Arc-shaped mesh bending machine for reinforcing mesh machining

A steel mesh and arc technology, which is applied in the field of arc bending machines, can solve the problems such as the inability to guarantee the processing quality and processing progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

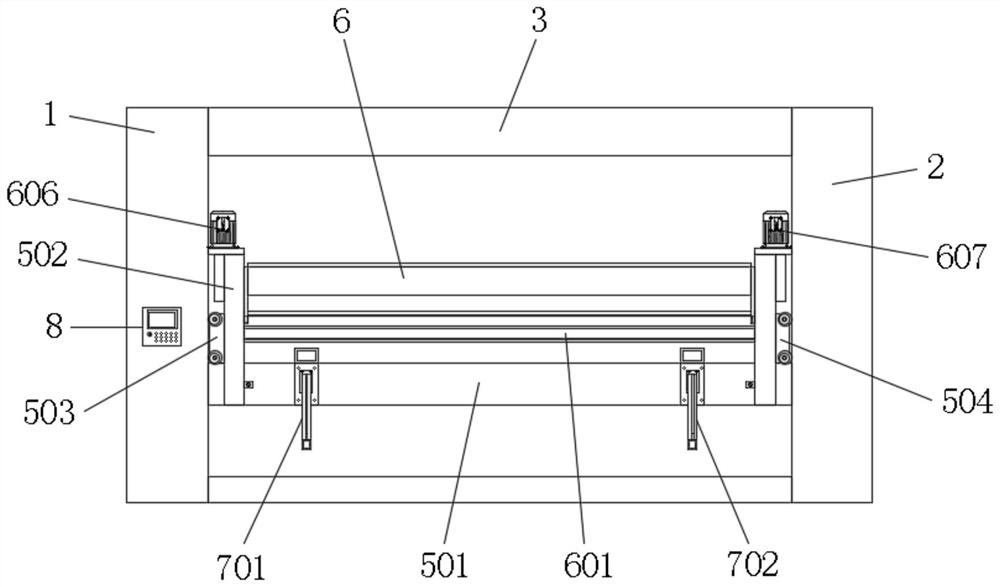

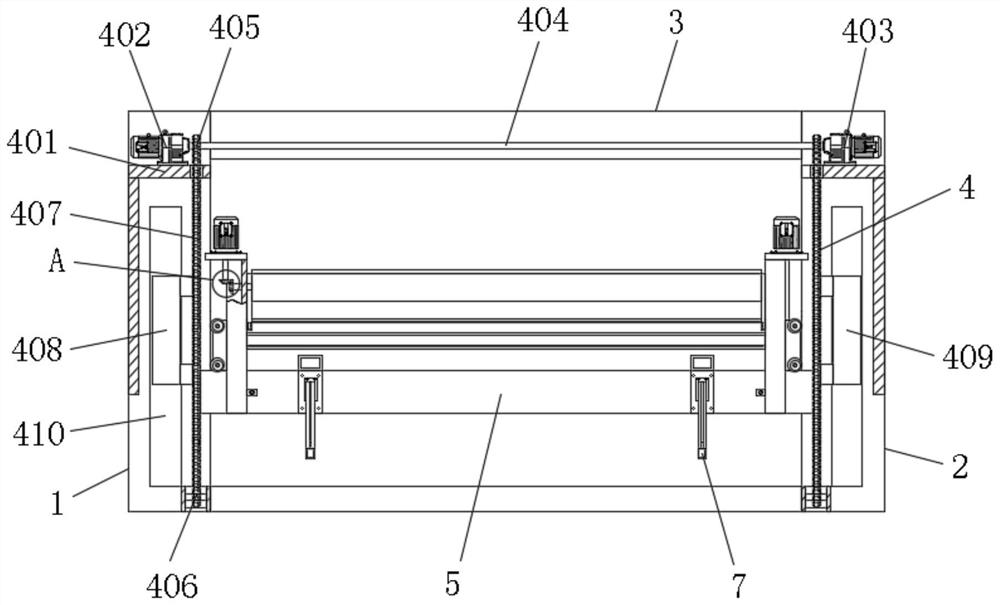

[0030] Such as Figure 1-5 As shown, the embodiment of the present invention provides an arc-shaped bending machine for steel mesh processing, including a first fixed frame 1 and a second fixed frame 2, and the top between the first fixed frame 1 and the second fixed frame 2 A connecting frame 3 is fixedly connected, and a lifting mechanism 4 is arranged between the first fixed frame 1 and the second fixed frame 2;

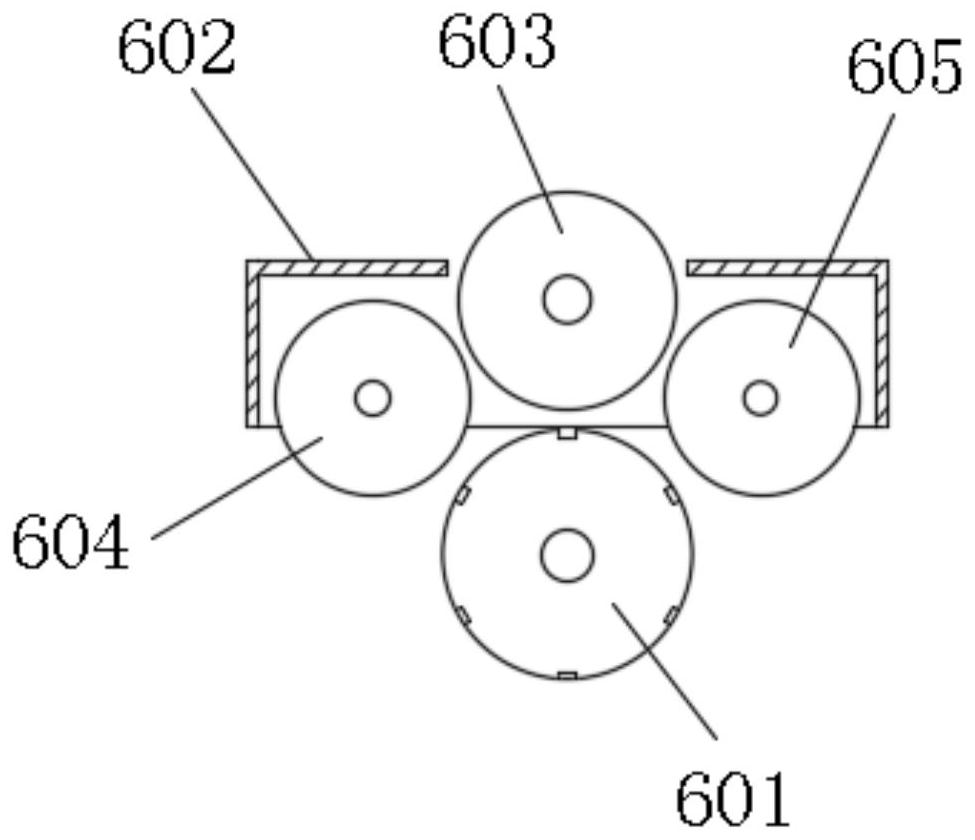

[0031] A supporting mechanism 5 corresponding to the lifting mechanism 4 is arranged between the first fixed frame 1 and the second fixed frame 2, and the top of the supporting mechanism 5 is provided with a bending net mechanism 6;

[0032] The front end of the support mechanism 5 is fixedly connected with a material guide mechanism 7, and the center of the front end of the first fixed frame 1 is equipped with a master control box 8.

[0033] Both ends of the connecting frame 3 are respectively fixedly connected to the first fixing frame 1 and the second fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com