Preparation method and application of functional carbon quantum dot modified Ag-In-Zn-S quantum dots

A technology of ag-in-zn-s and carbon quantum dots, applied in chemical instruments and methods, hydrogen production, physical/chemical process catalysts, etc., can solve problems such as no clear proof of the role of CDs, and reduce recombination efficiency , simple process, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of CDs-FcA precursor:

[0026] Pipette 12 mg of CDs and 0.48 mg of ferrocenecarboxylic acid solution into a transparent glass bottle and dilute to 20 mL of solution, transfer to an autoclave for hydrothermal reaction at 140 °C for 4 h, cool down and set aside.

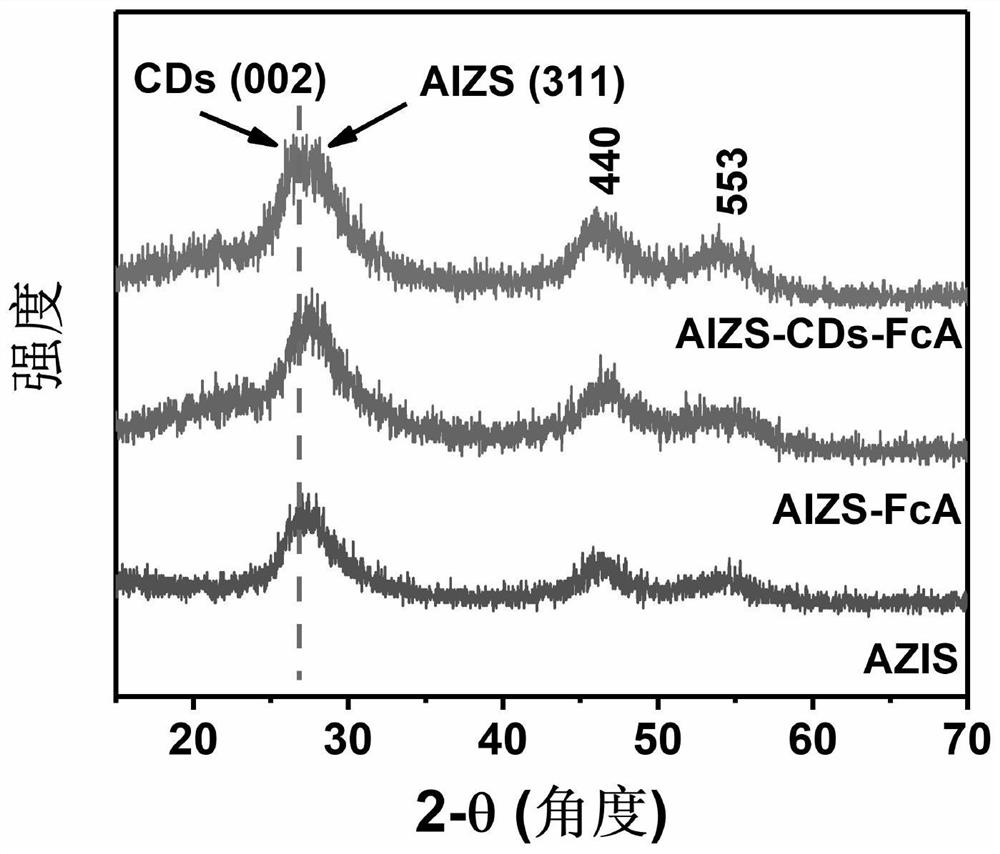

[0027] (2) Preparation of AIZS-CDs-FcA composite photocatalyst:

[0028] Weigh 0.0576 g of silver nitrate, 0.649 g of indium nitrate, 0.186 g of zinc acetate dihydrate, and 0.6058 g of L-cysteine and dissolve them in 50 g of water, mix the solutions and adjust the pH value of the solution to 8.5 with 1M NaOH and add step (1 ) CDs-FcA and 0.244 g thioacetamide were ultrasonically stirred, hydrothermally reacted in an autoclave at 110 °C for 4 hours, and after the reaction was centrifuged and washed, the AIZS-CDs-FcA composite photocatalyst was obtained.

[0029] Take 0.02 g of the catalyst and 0.528 g of L-ascorbic acid from the sample in (2) and add them to the photoreactor. 2 After the gas i...

Embodiment 2

[0031] (1) Preparation of CDs-FcA precursor:

[0032] Pipette 12 mg of CDs and 1.2 mg of ferrocenecarboxylic acid solution into a transparent glass bottle and dilute to 20 mL of solution, transfer to an autoclave for hydrothermal reaction at 140 °C for 4 h, cool down and set aside.

[0033] (2) Preparation of AIZS-CDs-FcA composite photocatalyst:

[0034] Weigh 0.0576 g of silver nitrate, 0.649 g of indium nitrate, 0.186 g of zinc acetate dihydrate, and 0.6058 g of L-cysteine and dissolve them in 50 g of water, mix the solutions and adjust the pH value of the solution to 8.5 with 1M NaOH and add step (1 ) CDs-FcA and 0.244 g thioacetamide were ultrasonically stirred, hydrothermally reacted in an autoclave at 110 °C for 4 hours, and after the reaction was centrifuged and washed, the AIZS-CDs-FcA composite photocatalyst was obtained.

[0035] Take 0.02 g of the catalyst and 0.528 g of L-ascorbic acid from the sample in (2) and add them to the photoreactor. 2 After the gas in...

Embodiment 3

[0037] (1) Preparation of CDs-FcA precursor:

[0038]Pipette 12 mg of CDs and 1.92 mg of ferrocenecarboxylic acid solution into a transparent glass bottle and dilute to 20 mL of solution, transfer to an autoclave for hydrothermal reaction at 140 °C for 4 h, cool down and set aside.

[0039] (2) Preparation of AIZS-CDs-FcA composite photocatalyst:

[0040] Weigh 0.0576 g of silver nitrate, 0.649 g of indium nitrate, 0.186 g of zinc acetate dihydrate, and 0.6058 g of L-cysteine and dissolve them in 50 g of water, mix the solutions and adjust the pH value of the solution to 8.5 with 1M NaOH and add step (1 ) CDs-FcA and 0.244 g thioacetamide were ultrasonically stirred, hydrothermally reacted in an autoclave at 110 °C for 4 hours, and after the reaction was centrifuged and washed, the AIZS-CDs-FcA composite photocatalyst was obtained.

[0041] Take 0.02 g of the catalyst and 0.528 g of L-ascorbic acid from the sample in (2) and add them to the photoreactor. 2 After the gas in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com