Sp3-bonded carbon materials, methods of manufacturing and uses thereof

A composite material and bonding technology, applied in chemical instruments and methods, metal material coating technology, nano-carbon, etc., can solve problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

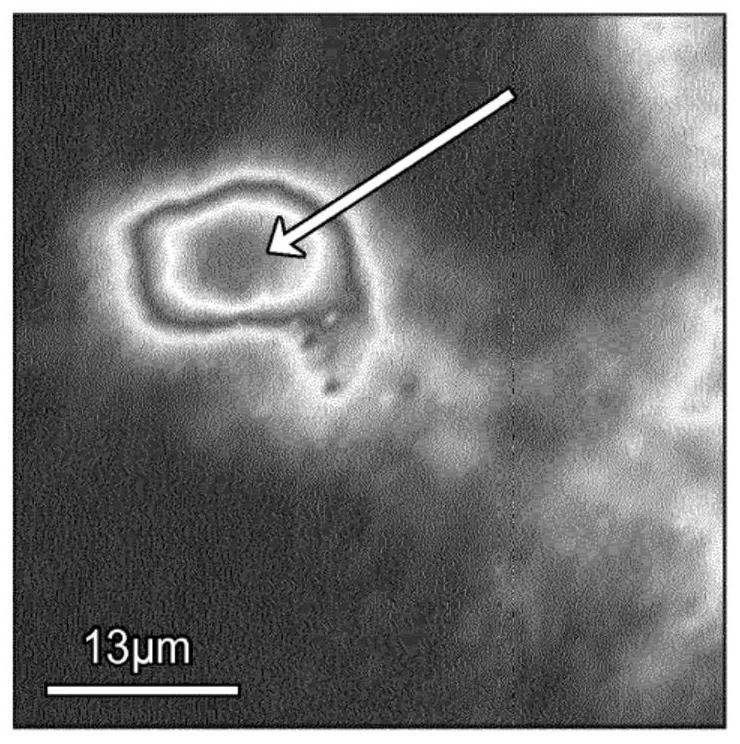

[0080] Commercial chemical vapor deposition (CVD) graphene films deposited on 3 mm ultrafine copper transmission electron microscopy (TEM) grids (2000 mesh) as received were used as graphene material (from Graphene Supermarket, SKU# SKU-TEM-CU-2000-025). by CVD by CH 4 Graphene was grown on Ni substrates at 1000°C and transferred to a commercial TEM grid using a polymer-free transfer method as described in W. Regan et al. (2010) to minimize contamination. The thickness of the CVD graphene film is 0.3nm to 2nm (1 to 6 monolayers). Typical graphene coverage of a TEM grid is 60% to 90%.

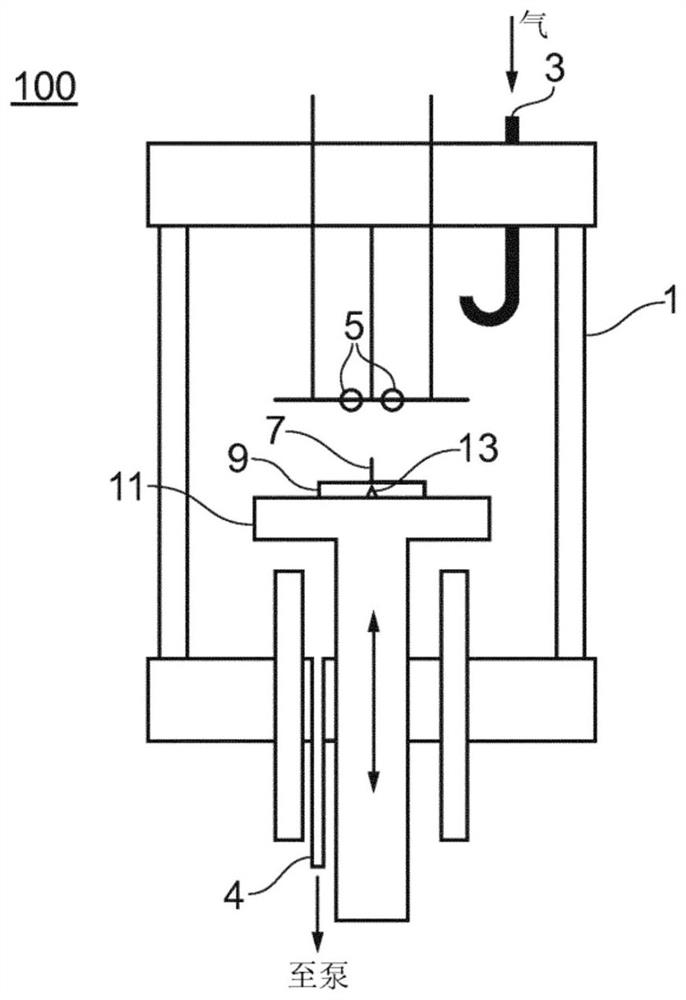

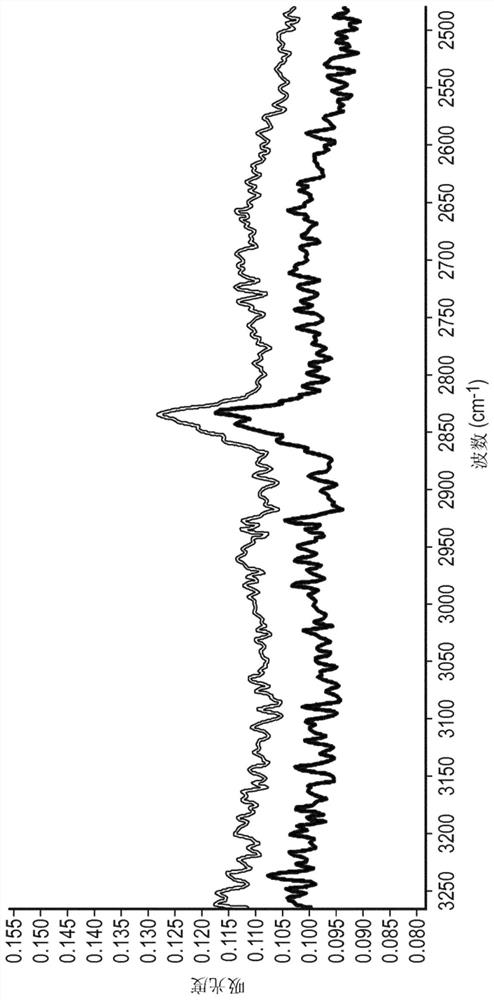

[0081] Hydrogenation and subsequent few-layer graphene to ultrathin crystalline sp 3 Structural transformation of bonded carbon sheets. The schematic diagram of the system is in figure 1 shown in and described above.

[0082] The reactor is a six-way cross stainless steel vacuum chamber. It was fluid cooled (15% water, 75% ethylene glycol at 18° C.) with brazed copper tubes covered with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com