Hard cladding rare-earth-doped optical fiber and preparation method thereof

A rare earth-doped, cladding technology, applied in cladding optical fibers, multi-layer core/cladding optical fibers, graded index core/cladding optical fibers, etc. The effect of drawing yield, avoiding air bubbles, and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] to combine figure 1 with figure 2 As shown, the embodiment of the present application provides a method for preparing the above-mentioned hard-clad rare earth-doped optical fiber, the preparation method includes the following steps:

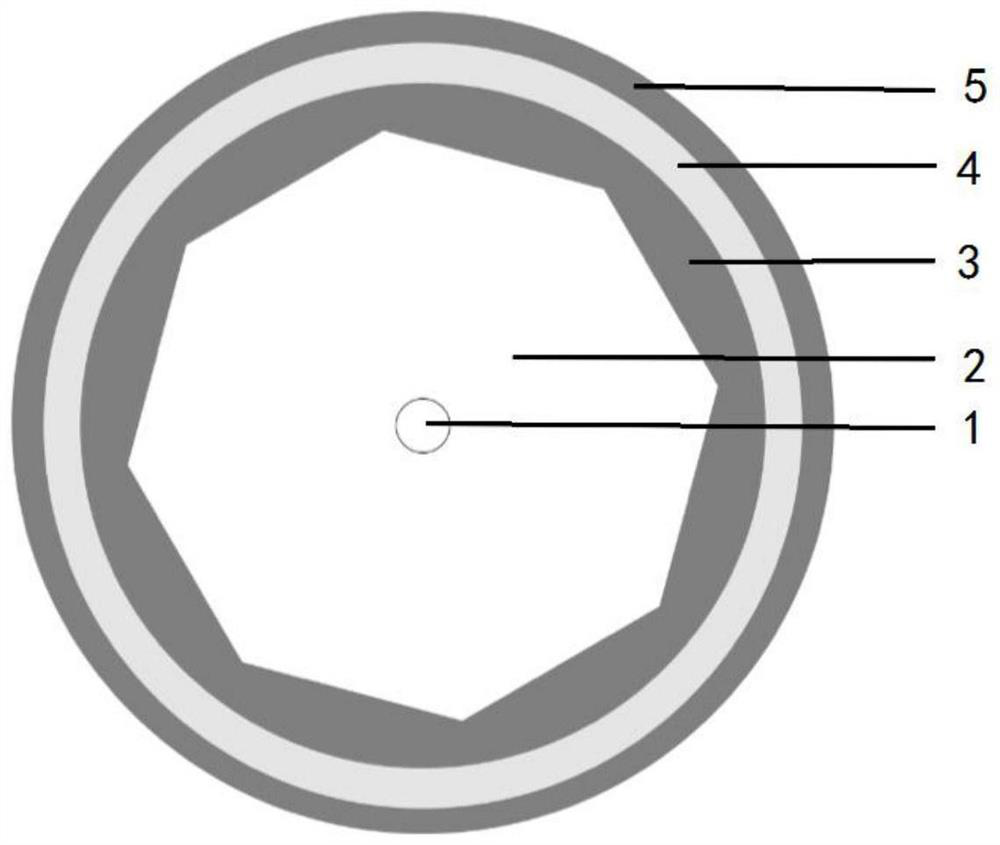

[0049] 101: Prepare an octagonal rare-earth-doped mandrel. The octagonal rare-earth-doped mandrel includes a core layer 1 and a quartz cladding 2 located outside the core layer 1. The outside of the cross-section of the quartz cladding 2 is octagonal; preferably, eight The numerical aperture NA range of the polygonal rare earth-doped mandrel is between 0.04 and 0.20;

[0050] 102: Prepare a fluorine-doped sleeve, which includes a fluorine-doped cladding 3 and a quartz substrate located outside the fluorine-doped cladding 3; it should be noted that step 101 and step 102 can be performed at the same time or first A fluorine-doped casing is prepared, and an octagonal rare-earth-doped mandrel is prepared.

[0051] 103: Insert the octagonal...

Embodiment 1

[0067] Example 1: 100 / 400 / 480 hard cladding ytterbium-doped fiber

[0068] Such as figure 1 As shown, the 100 / 400 / 480 hard cladding ytterbium-doped fiber includes a core layer 1, a quartz cladding 2, a fluorine-doped cladding 3, a low refractive index coating 4, and a high temperature resistant Outer coating5.

[0069] The manufacturing method of the hard cladding ytterbium-doped optical fiber is as follows:

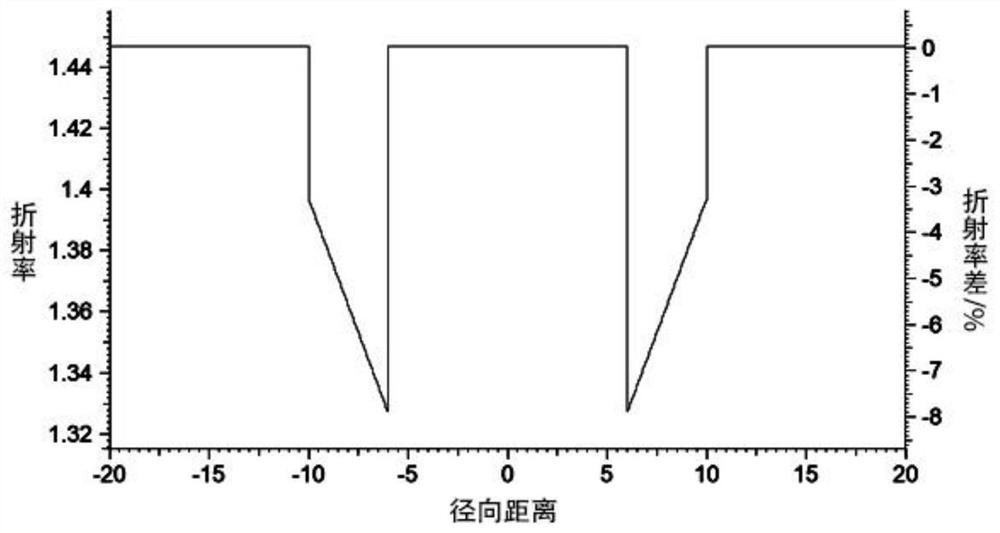

[0070] (1) The ytterbium-doped mandrel was prepared by MCVD vapor phase doping process. The core diameter of the ytterbium-doped mandrel is 3mm, and the outer diameter of the ytterbium-doped mandrel is 16mm. The ytterbium Yb ion doping concentration in the ytterbium-doped mandrel is 0.25mol%, the aluminum Al ion doping concentration is 2.5mol%, and the phosphorus P ion doping concentration is 2.0mol%. The numerical aperture NA of the ytterbium-doped mandrel is 0.11.

[0071] (2) Grinding the ytterbium-doped mandrel in an octagonal shape according to the target core-...

Embodiment 2 00

[0079] Embodiment 2 300 / 400 / 480 hard cladding ytterbium-doped optical fiber

[0080] Such as figure 1 As shown, the 300 / 400 / 480 hard cladding ytterbium-doped fiber includes a core layer 1, a quartz cladding 2, a fluorine-doped cladding 3, a low refractive index coating 4, and a high temperature resistant Outer coating5.

[0081] The manufacturing method of the hard cladding ytterbium-doped optical fiber is as follows:

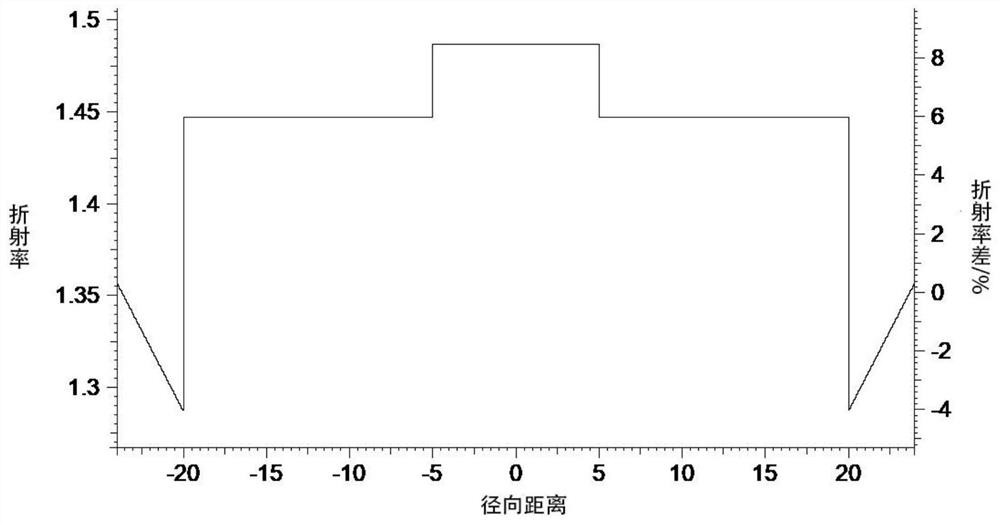

[0082] (1) The ytterbium-doped mandrel was prepared by MCVD vapor phase doping process. The core diameter of the ytterbium-doped mandrel is 8mm, and the outer diameter of the ytterbium-doped mandrel is 21mm. The Yb ion doping concentration in the ytterbium-doped mandrel is 0.3 mol%, the Al ion doping concentration is 3.0 mol%, and the P doping concentration is 2.8 mol%. The numerical aperture NA of the ytterbium-doped mandrel is 0.10.

[0083] (2) The octagonal grinding of the ytterbium-doped mandrel was carried out according to the target core-to-wrap rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com