Steel member plane stress detection method based on ultrasonic transverse and longitudinal wave combination

A technology of plane stress and steel components, which is applied in the analysis of solids by using sound waves/ultrasonic waves/infrasonic waves, material analysis by using sound waves/ultrasonic waves/infrasonic waves, and measuring devices, etc. Information and other issues, to achieve the effect of simple test process, high sensitivity and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

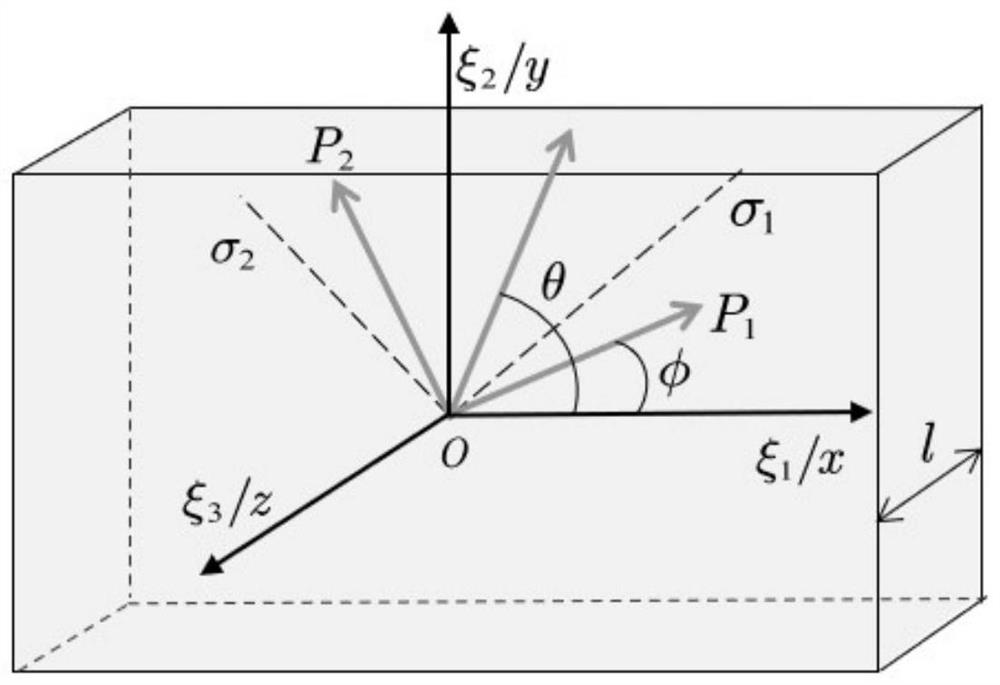

Method used

Image

Examples

Embodiment 1

[0180] The present invention selects the commonly used Q235b steel plate test piece, the thickness is 10mm, and its length and width are 250mm and 80mm respectively. Detection was carried out according to the detection steps mentioned in Example 1.

[0181] In the first step, a unidirectional step-by-step loading experiment is carried out on the steel plate specimen along the width direction, with a stress gradient of 5 MPa. In order to keep the steel plate in an elastic state, the upper limit of the loading stress is 165 MPa.

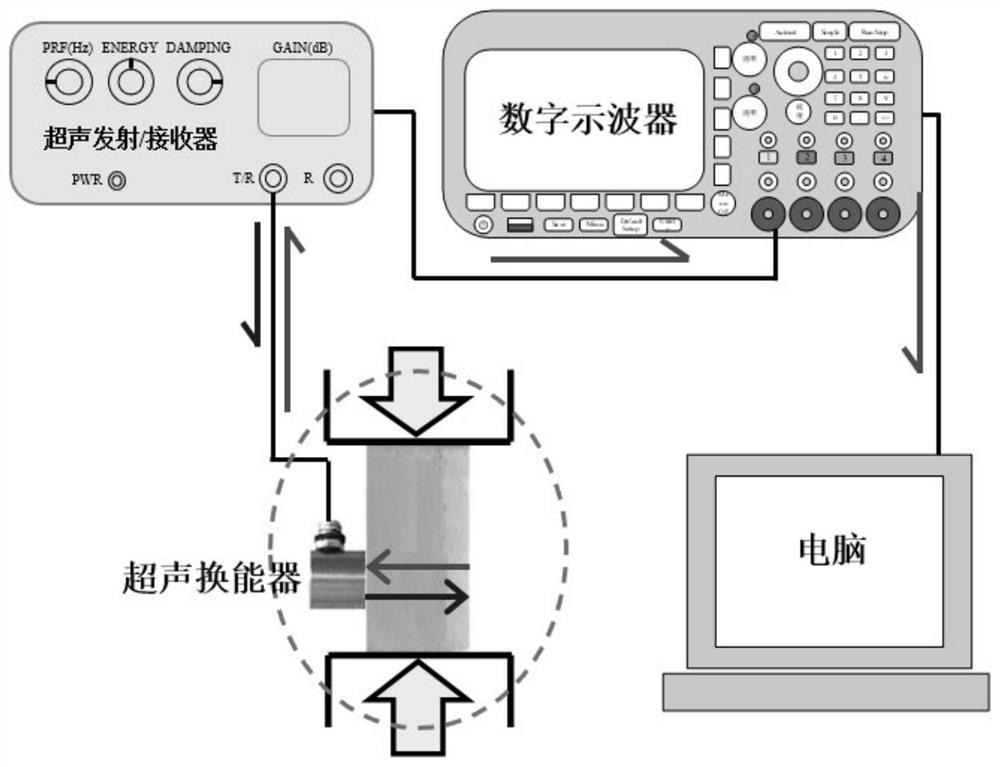

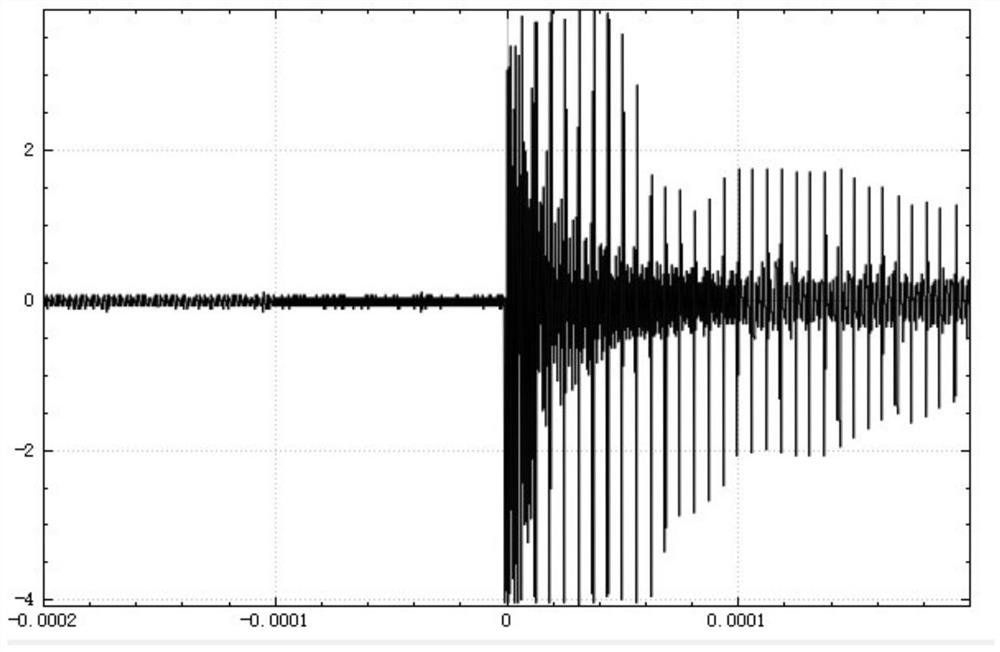

[0182] In the second step, within the stress holding time of each gradient, the ultrasonic shear wave and longitudinal wave are sequentially emitted at the calibration point, and the shear wave probe is incident on the ultrasonic shear wave pulse at 60° from the horizontal direction, and the first group of echo time domain signals are collected and stored ,Such as image 3 As shown; the shear wave probe is rotated 90°, incident again at an angle of 15...

Embodiment 2

[0195] The present invention selects a Q345b steel plate with a thickness of 10mm as the test object, and its length and width are 250mm and 80mm respectively. The calibration experiment and detection experiment were carried out according to the detection steps mentioned in Example 1. The results of the calibration experiment are shown in Table 4, and the values of the obtained plane stress acoustic elastic coefficients are shown in Table 5. Also for the four detection points A1, A2, A3 and A4, the strain gauge method was used as a comparison, and the comparison results are shown in Table 6.

[0196] Table 4 Q345b steel plate calibration test results (f = 5MHz)

[0197]

[0198]

[0199] Table 5 Calibration value of plane stress acoustoelastic coefficient of Q345b steel plate (f=5MHz)

[0200]

[0201] Table 6 Test results of plane stress information of Q345b steel plate

[0202]

[0203]

[0204] It can be seen from the examples that the non-destructive det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com