Single-stage multi-effect network chain closed coal slime drying system

A drying system and network chain technology, applied in the direction of drying solid materials, drying gas arrangement, drying solid materials without heating, etc., can solve the problems of whitening, limited heat source, pollutant discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

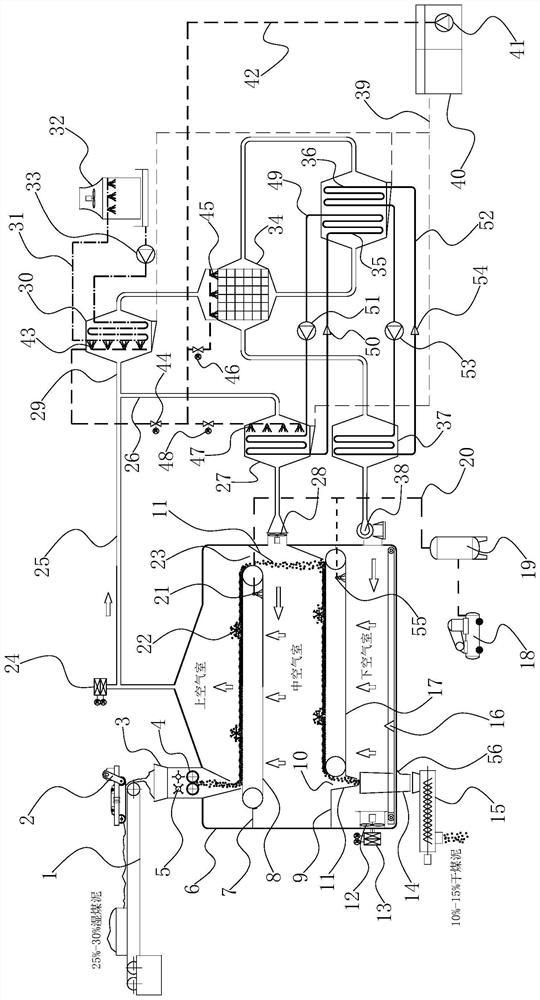

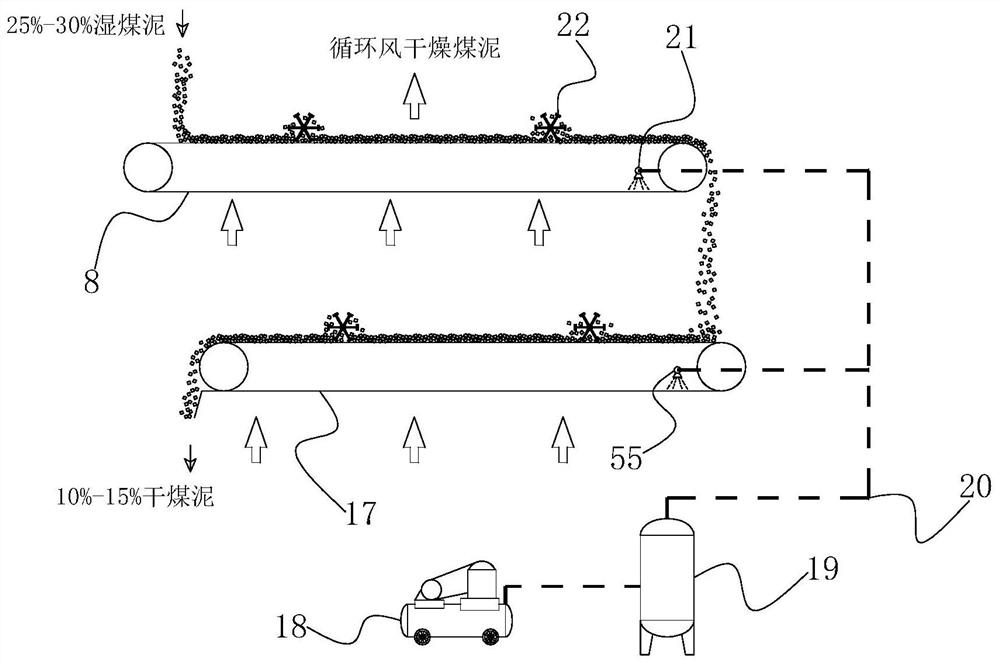

[0042] Such as figure 1 shown, combined with Figure 2-22 As shown, the single-stage multi-effect net chain closed coal slime drying system of the present invention includes a dryer and an air supply device, and the dryer includes a drying chamber 6, and the top of the drying chamber 6 is provided with a feed port, so The bottom of the drying chamber 6 is provided with a discharge port, and the drying chamber 6 is sequentially provided with an upper chain conveyor unit and a lower net chain conveyor unit from top to bottom. The on-line conveyor unit is provided with at least one on-line conveyor 8, and when there are more than two on-line conveyors 8, the two or more on-line conveyors 8 are arranged in sequence along the vertical direction. The lower net chain conveyor unit is provided with at least one lower net chain conveyor 17, and when the lower net chain conveyor 17 is set to more than two, the lower net chain conveyors 17 of more than two are sequentially moved along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com