Intelligent exhaust explosion-proof hydrogen storage cabinet

A hydrogen storage and intelligent technology, applied in the field of hydrogen storage cabinets, can solve the problems of reduced safety and low safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

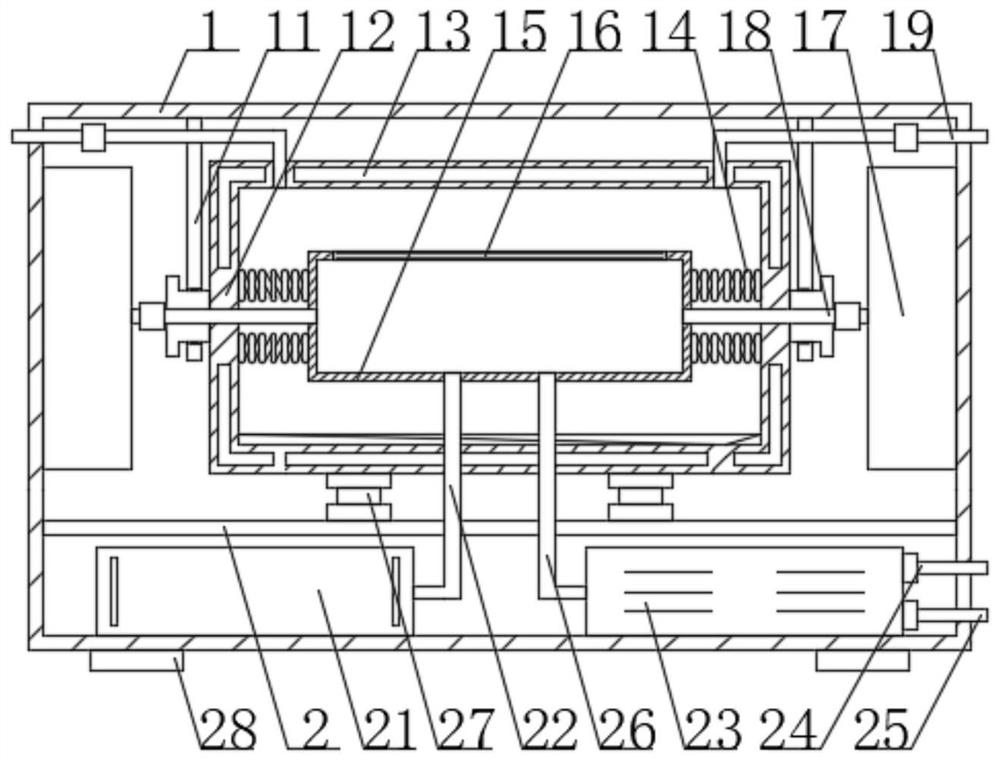

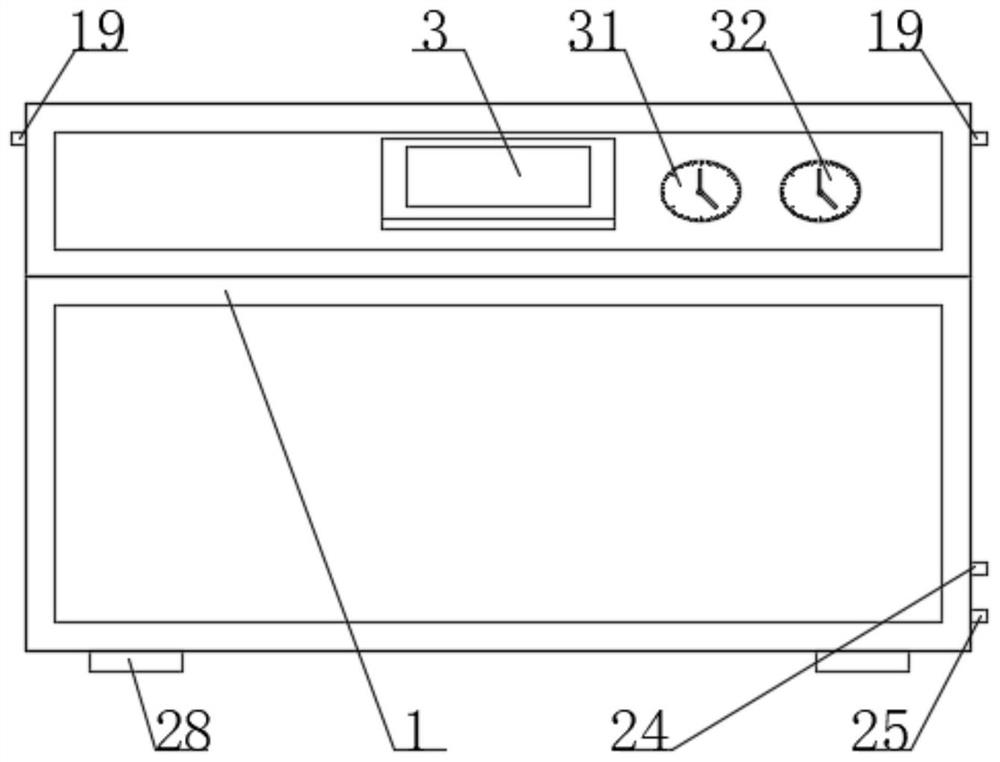

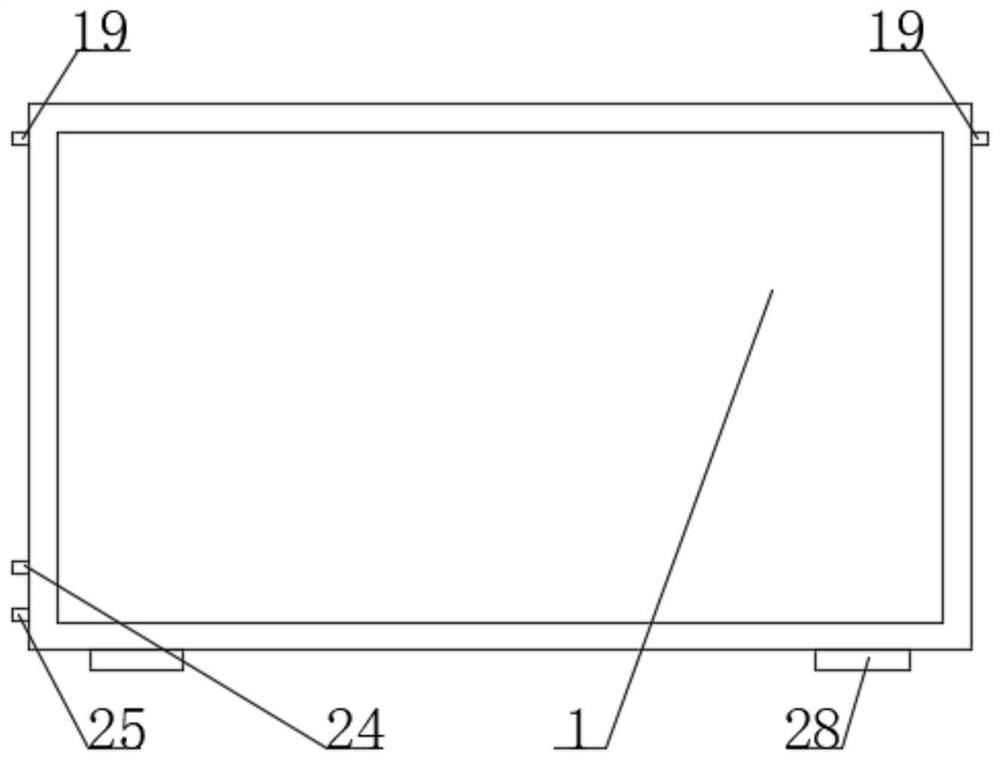

[0026] see Figure 1-7 , the present invention provides a technical solution: an intelligent exhaust explosion-proof hydrogen storage cabinet, including a cabinet body 1 and a touch terminal 3, and both sides of the middle part of the upper surface of the inner wall of the cabinet body 1 are fixedly connected with mounting frames 11 by bolts, The mounting frame 11 has a U-shaped structure, and the middle parts of the adjacent surfaces of the two mounting frames 11 are fixedly connected with a hydrogen storage tank 12 by bolts and flanges near the bottom end. The hydrogen storage tank 12 can effectively store hydrogen, so The heat storage energy storage layer 13 is inlaid in the inner wall of the hydrogen storage tank 12, and the heat storage energy storage layer 13 can effectively realize that when the lanthanum-nickel alloy powder absorbs hydrogen, the heat storage energy storage layer 13 quickly absorbs the heat released by the heat storage energy storage layer 13, and Tempo...

Embodiment 2

[0030] see Figure 1-7, the present invention provides a technical solution: an intelligent exhaust explosion-proof hydrogen storage cabinet, including a cabinet body 1 and a touch terminal 3, and both sides of the middle part of the upper surface of the inner wall of the cabinet body 1 are fixedly connected with mounting frames 11 by bolts, The mounting frame 11 has a U-shaped structure, and the middle parts of the adjacent surfaces of the two mounting frames 11 are fixedly connected with a hydrogen storage tank 12 by bolts and flanges near the bottom end. The hydrogen storage tank 12 can effectively store hydrogen, so The heat storage energy storage layer 13 is inlaid in the inner wall of the hydrogen storage tank 12, and the heat storage energy storage layer 13 can effectively realize that when the lanthanum-nickel alloy powder absorbs hydrogen, the heat storage energy storage layer 13 quickly absorbs the heat released by the heat storage energy storage layer 13, and Tempor...

Embodiment 3

[0034] see Figure 1-7 , the present invention provides a technical solution: an intelligent exhaust explosion-proof hydrogen storage cabinet, including a cabinet body 1 and a touch terminal 3, and both sides of the middle part of the upper surface of the inner wall of the cabinet body 1 are fixedly connected with mounting frames 11 by bolts, The mounting frame 11 has a U-shaped structure, and the middle parts of the adjacent surfaces of the two mounting frames 11 are fixedly connected with a hydrogen storage tank 12 by bolts and flanges near the bottom end. The hydrogen storage tank 12 can effectively store hydrogen, so The heat storage energy storage layer 13 is inlaid in the inner wall of the hydrogen storage tank 12, and the heat storage energy storage layer 13 can effectively realize that when the lanthanum-nickel alloy powder absorbs hydrogen, the heat storage energy storage layer 13 quickly absorbs the heat released by the heat storage energy storage layer 13, and Tempo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com