Preparation process of polyamide-polyester blended fabric with ice-cold feeling

A technology of blended fabrics and preparation process, applied in the field of fabric textiles, can solve the problems of nylon fabrics losing coolness and other problems, and achieve the effects of good drape, improved lubricity, and improved comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

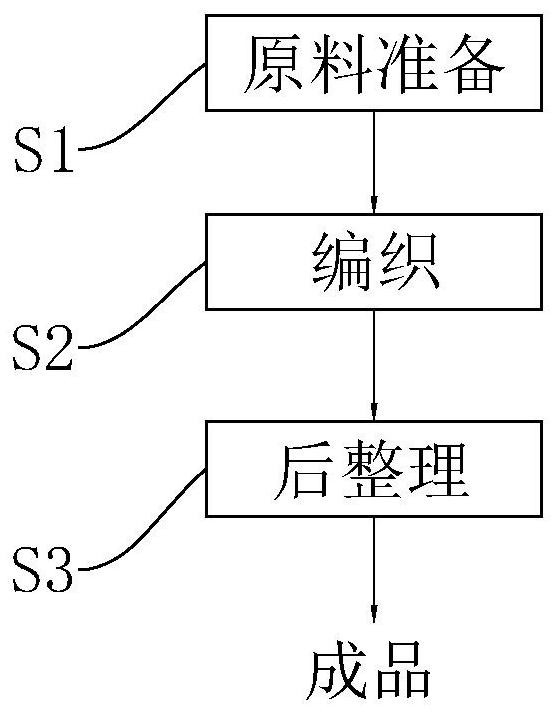

[0048] refer to figure 1 , this embodiment discloses a preparation process of a nylon-polyester blended fabric with a cool feeling, comprising the following steps:

[0049] S1: Raw material preparation. Prepare cool feeling nylon yarn, and prepare polyester yarn at the same time. Among them, the cool-feeling nylon yarn is selected from the summer textile-specific functional cool-feeling nylon yarn sold by Nanchang Zhushengfu Nano Technology Co., Ltd.; the polyester yarn is selected from the 140D woven thread polyester yarn high-elasticity yarn sold by Dongguan Dalang Chunxing Wool Yarn Co., Ltd. .

[0050]S2: Weaving. The cool-feeling nylon yarn and polyester yarn prepared by S1 are interwoven with high-quality professional double-sided jacquard circular knitting machine sold by Zhoushan Huaxing Machinery Co., Ltd. to form a fabric, so that the cool-feeling nylon yarn and polyester yarn are located on both sides of the fabric.

[0051] S3: finishing. Roll up the fabric af...

Embodiment 2

[0054] The difference from Example 1 is that, S1: In the preparation of raw materials, the cool-feeling nylon yarn includes the following preparation methods:

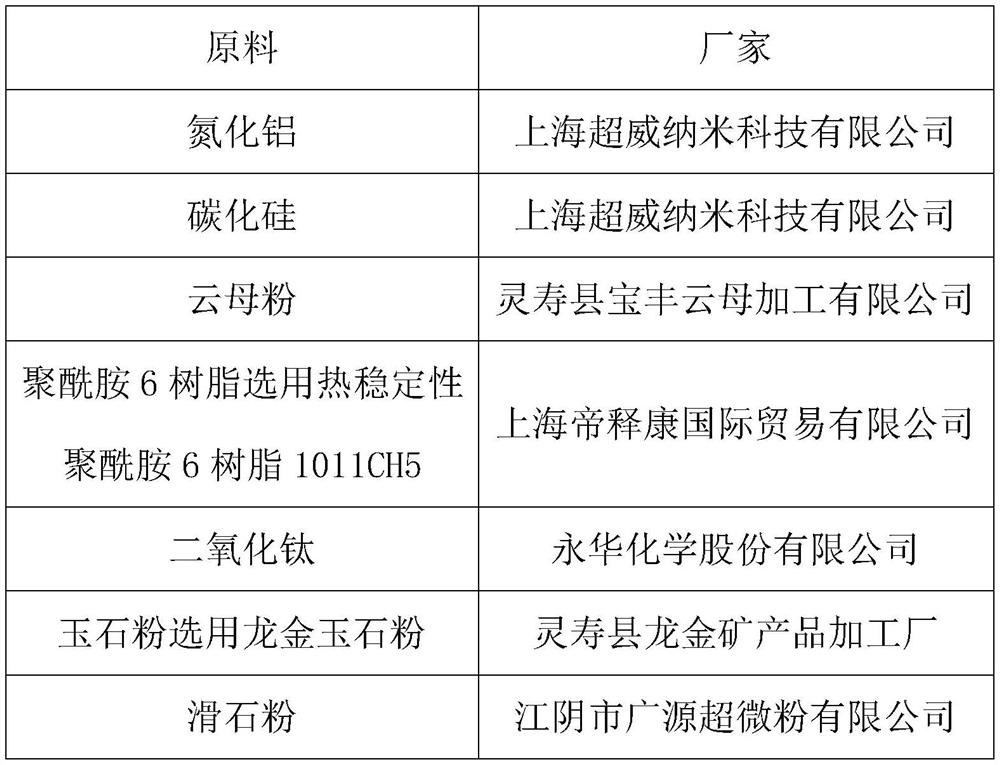

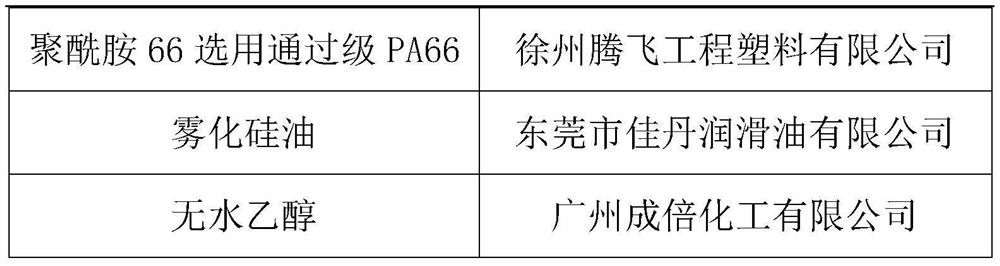

[0055] S11: Transport the polyamide resin and the cooling composition to the drum for drying for 48 hours, and set the drying temperature in the drum to 120°C; the raw materials of the cooling composition include 25 parts by weight of aluminum nitride, 13 parts of silicon carbide part and 50 parts of mica powder; the weight ratio of cooling composition and polyamide resin is 5:100. The particle size of each substance in the cooling composition is 25nm. Among them, polyamide 66 resin is selected as the polyamide resin.

[0056] S12: Transport the material treated in S11 to the screw extruder, and adjust the temperature in the screw extruder to 300°C, so that the polyamide resin is completely molten. At this time, the components of the cooling composition Distribute in the polyamide resin in the molten state in the for...

Embodiment 3

[0061] The difference from Example 2 is that the raw material of the cooling composition also includes 6 parts by weight of titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com