Sewage treatment device

A technology of sewage treatment device and aqueduct, which is applied in water/sewage treatment, biological treatment device, biological water/sewage treatment, etc., can solve the problems of requiring personnel and high energy consumption for sewage treatment, and reduce workload and process routes. And specifications and models, easy to deal with the effect of a large amount of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

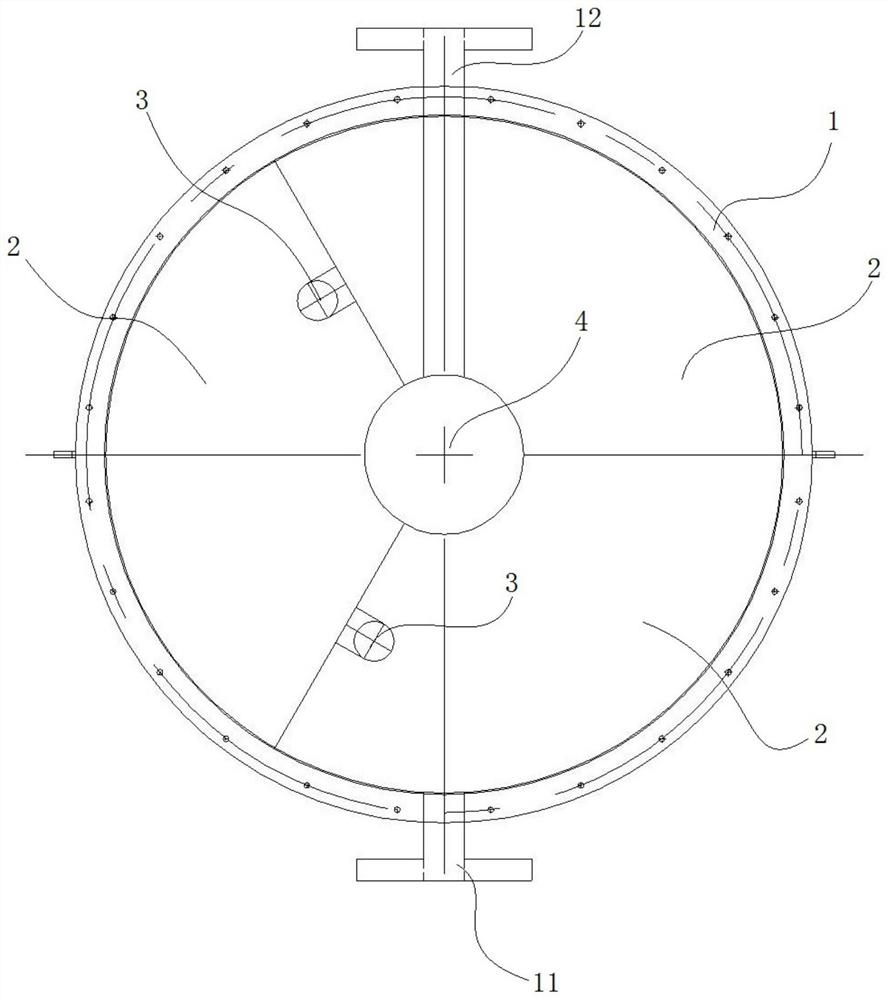

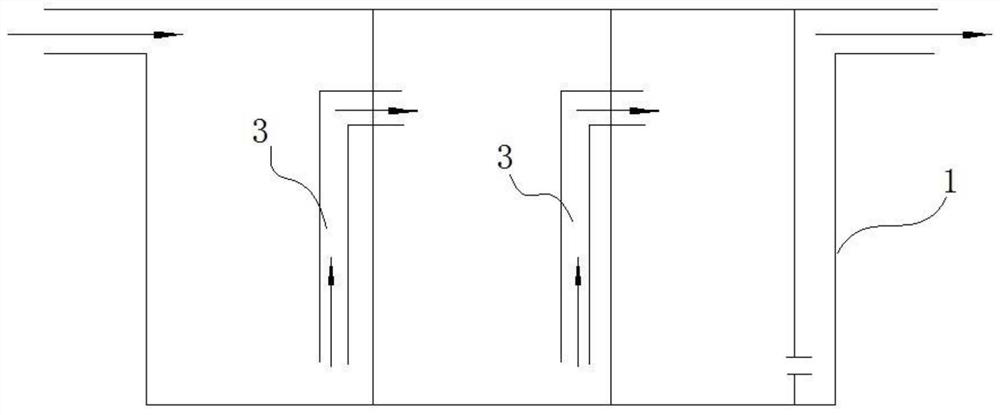

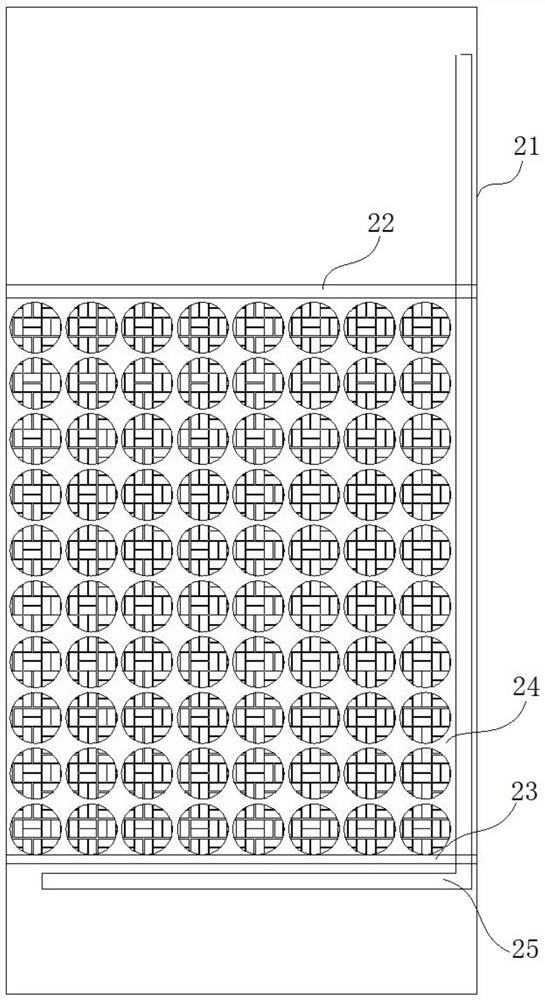

[0029] Such as figure 1 and figure 2 As shown, a sewage treatment device according to an embodiment of the present invention includes a tank body 1 and a plurality of divided buckets 2 arranged in the tank body 1. In this embodiment, three divided buckets 2 are provided, and three Each divided barrel 2 is evenly arranged in the tank body 1, and the barrel walls of adjacent divided barrels 2 are pasted together without welding; in other embodiments, the divided barrels 2 can also be other numbers, preferably, divided The number of grid buckets 2 is greater than or equal to 5; the upper part of the tank body 1 is provided with a water inlet 11 and a water outlet 12, and the water inlet 11 and the water outlet 12 are respectively connected to different grid buckets 2; a plurality of grid buckets 2 The water guide pipe 3 is sequentially communicated, and the first end of the water guide pipe 3 is located at the bottom of a compartment bucket 2, and the second end of the water gu...

no. 2 example

[0041] The difference with the first embodiment is that the number of compartment buckets 2 is different, such as Figure 5 As shown, six compartments 2 are arranged in the tank body 1, and the barrel walls of each compartment 2 are attached together without welding and fixing. Sewage is graded and treated through six compartments 2 .

[0042] To sum up, the embodiment of the present invention provides a sewage treatment device, which sequentially treats the sewage by arranging a plurality of compartments 2 in the tank body 1, and can train the microorganisms in the sewage to form a hierarchical food chain relationship, so that no Personnel are required to maintain and operate on site, and the emissions can reach the standard without being on duty. Moreover, the present invention carries out modular processing on the tank body 1, which facilitates the treatment of a large amount of sewage. The compartment 2 can be manufactured in batches, reducing the process routes and spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com