A kind of ultrafiltration polyethylene porous membrane for water treatment and its preparation process

A preparation process, polyethylene technology, applied in water/sewage treatment, water/sludge/sewage treatment, osmotic/dialysis water/sewage treatment, etc., can solve problems such as performance degradation, permanent defects, performance degradation, etc. Long antibacterial life, high practicability, tightly combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

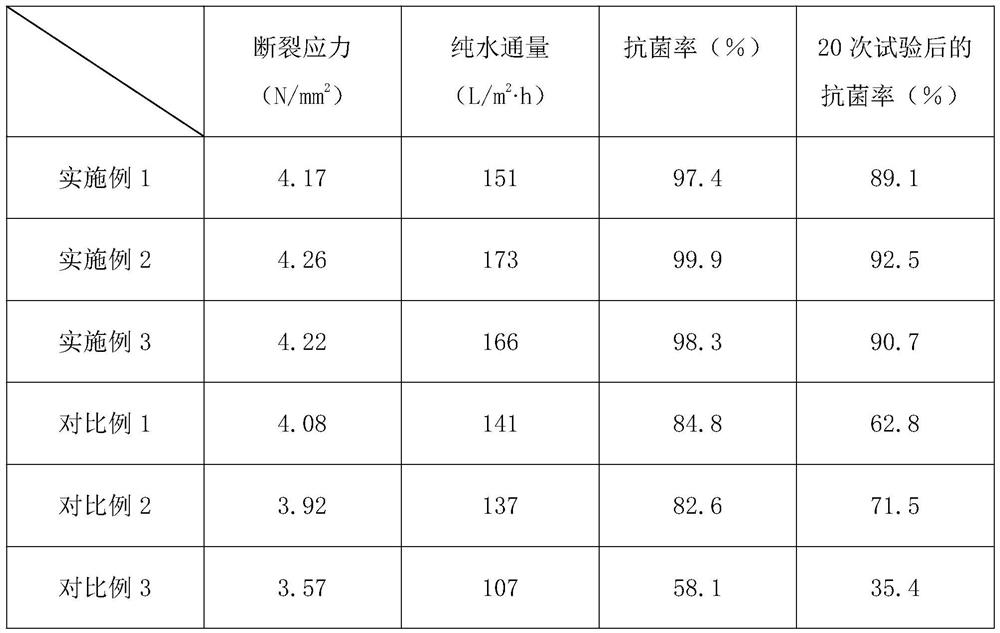

Examples

Embodiment 1

[0049] A preparation process of ultrafiltration polyethylene porous membrane for water treatment, comprising the following steps:

[0050] S1: polyethylene cross-linking treatment, loaded with spherical nano-copper, to obtain material A;

[0051] S2: Grafting 5,5-dimethylhydantoin on the surface of material A to prepare material B, and reacting material B in dichloropropanol and sodium hydroxide solution to prepare cross-linked polyethylene;

[0052] S3: surface-treat nano-titanium dioxide with sodium laurate, and coat nano-titanium dioxide with quaternary ammonium chitosan to prepare chitosan antibacterial salt;

[0053] S4: Stir cross-linked polyethylene and chitosan antibacterial salt, and ultrasonically disperse to obtain material C;

[0054] S5: Melting and blending the material C and paraffin, casting, stretching, removing paraffin, and heat treatment to obtain a polyethylene ultrafiltration membrane.

[0055] Among them, S1:

[0056] (1) Soak polyethylene in acetone ...

Embodiment 2

[0068] A preparation process of ultrafiltration polyethylene porous membrane for water treatment, comprising the following steps:

[0069] S1: polyethylene cross-linking treatment, loaded with spherical nano-copper, to obtain material A;

[0070] S2: Grafting 5,5-dimethylhydantoin on the surface of material A to obtain substance B, and reacting substance B in dichloropropanol and sodium hydroxide solution to obtain cross-linked polyethylene;

[0071] S3: surface-treat nano-titanium dioxide with sodium laurate, and coat nano-titanium dioxide with quaternary ammonium chitosan to prepare chitosan antibacterial salt;

[0072] S4: Stir cross-linked polyethylene and chitosan antibacterial salt, and ultrasonically disperse to obtain material C;

[0073] S5: Melting and blending the material C and paraffin, casting, stretching, removing paraffin, and heat treatment to obtain a polyethylene ultrafiltration membrane.

[0074] Among them, S1:

[0075] (1) Soak polyethylene in acetone ...

Embodiment 3

[0087] A preparation process of ultrafiltration polyethylene porous membrane for water treatment, comprising the following steps:

[0088] S1: polyethylene cross-linking treatment, loaded with spherical nano-copper, to obtain material A;

[0089] S2: Grafting 5,5-dimethylhydantoin on the surface of material A to obtain material B, and reacting material B in dichloropropanol and sodium hydroxide solution to obtain cross-linked polyethylene;

[0090] S3: modify the surface of nano-titanium dioxide with sodium laurate, and coat nano-titanium dioxide with quaternary ammonium chitosan to prepare chitosan antibacterial salt;

[0091] S4: Stir cross-linked polyethylene and chitosan antibacterial salt, and ultrasonically disperse to obtain material C;

[0092] S5: Melting and blending the material C and paraffin, casting, stretching, removing paraffin, and heat treatment to obtain a polyethylene ultrafiltration membrane.

[0093] Among them, S1:

[0094] (1) Soak polyethylene in ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com