Device and method for optical micro-rheology for characterizing viscoelasticity of soft substance

A viscoelastic, soft matter technology, applied in the field of optical micro-rheological measurement devices based on optical vortex motion statistics, can solve the problems of complex design, complex calculation, high price, etc., and achieve the effect of simple structure and simple data processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

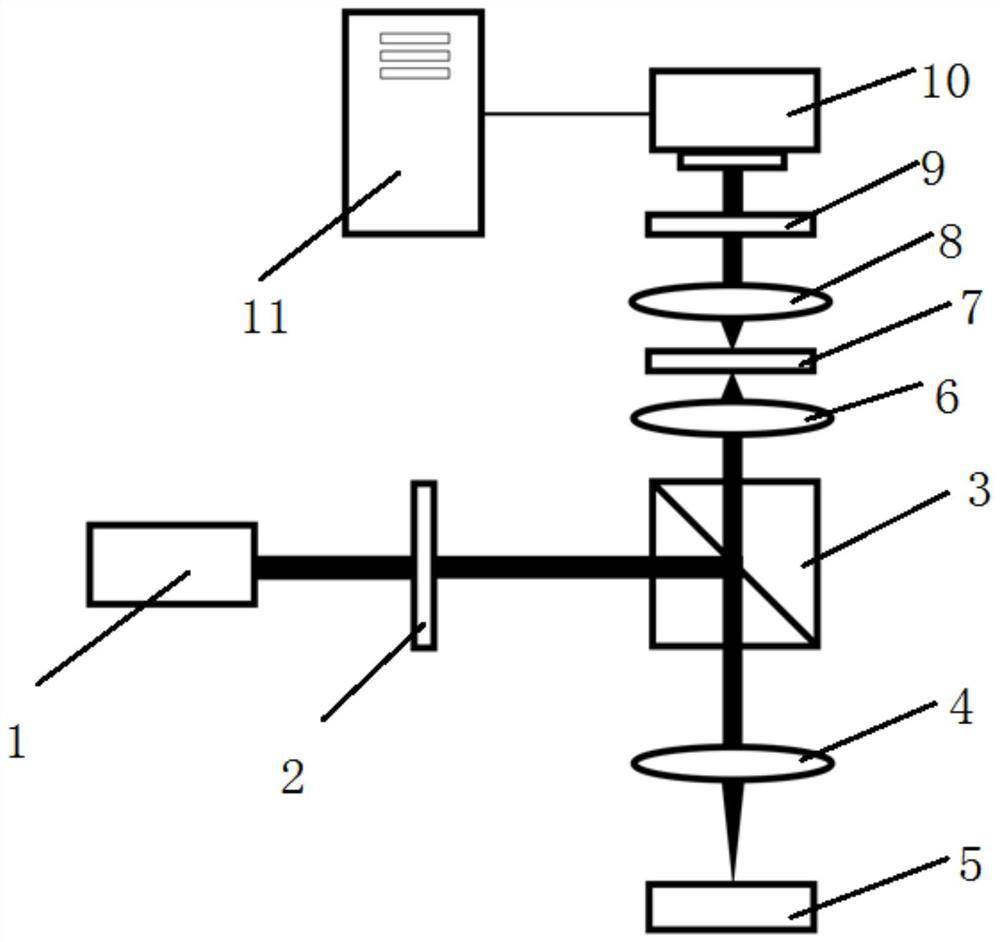

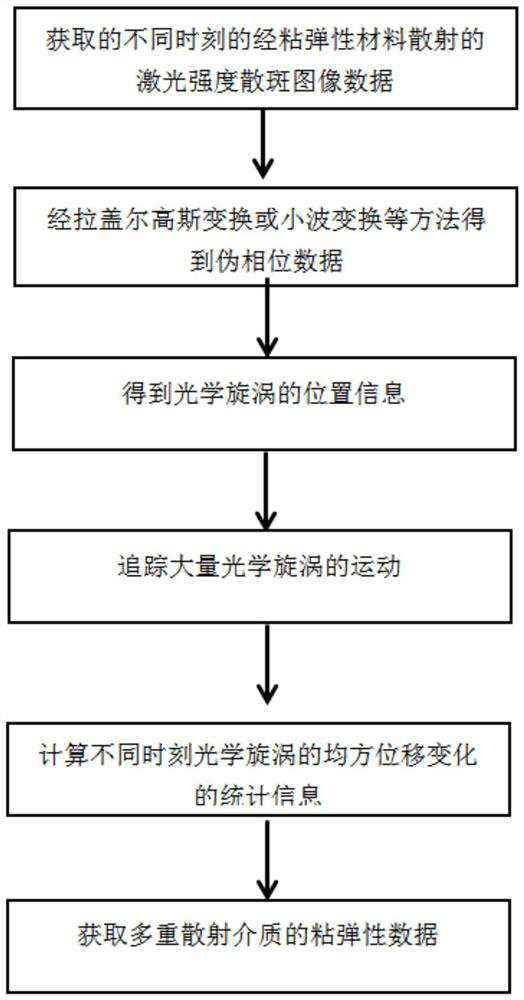

Method used

Image

Examples

specific Embodiment

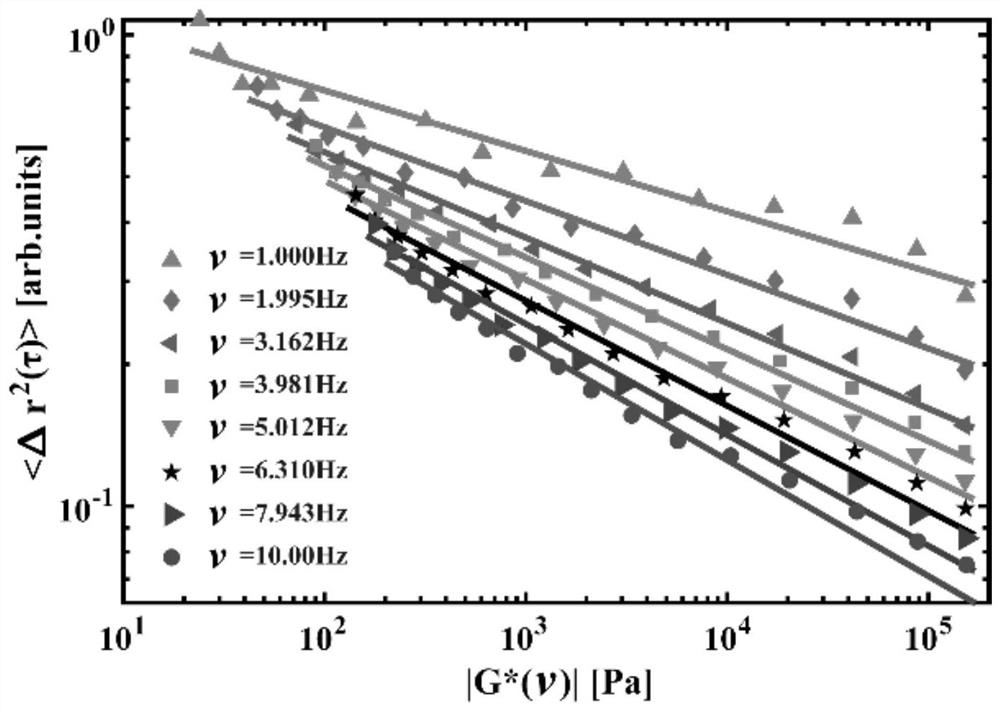

[0059] The following are specific examples: adopting polydimethylsiloxane (PDMS) adding an appropriate amount of titanium dioxide nanoparticles as a sample, adding titanium dioxide powder to obtain sufficient scattering intensity, PDMS will gradually solidify into a solid after adding a curing agent, and its viscosity The elastic modulus ranges from tens of Pascals before the curing agent is reinforced to hundreds of thousands of Pascals after it is completely solidified. At different time points during the solidification process, the samples have different viscoelastic moduli. We test the sample at different time points in the solidification process to obtain the mean square displacement of the optical vortex point at different times, which can be used to characterize the viscoelastic properties of the sample to be tested.

[0060] image 3 It is the corresponding relationship between the MSD (mean square displacement) of the optical vortex of the material obtained by the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com