Heat exchange structure for water heater

A heat exchange structure, water heater technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as affecting user experience, poor heat exchange efficiency, water temperature fluctuates cold and hot, etc. Exchange efficiency, stable and balanced water temperature, and the effect of avoiding uneven water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than Full examples.

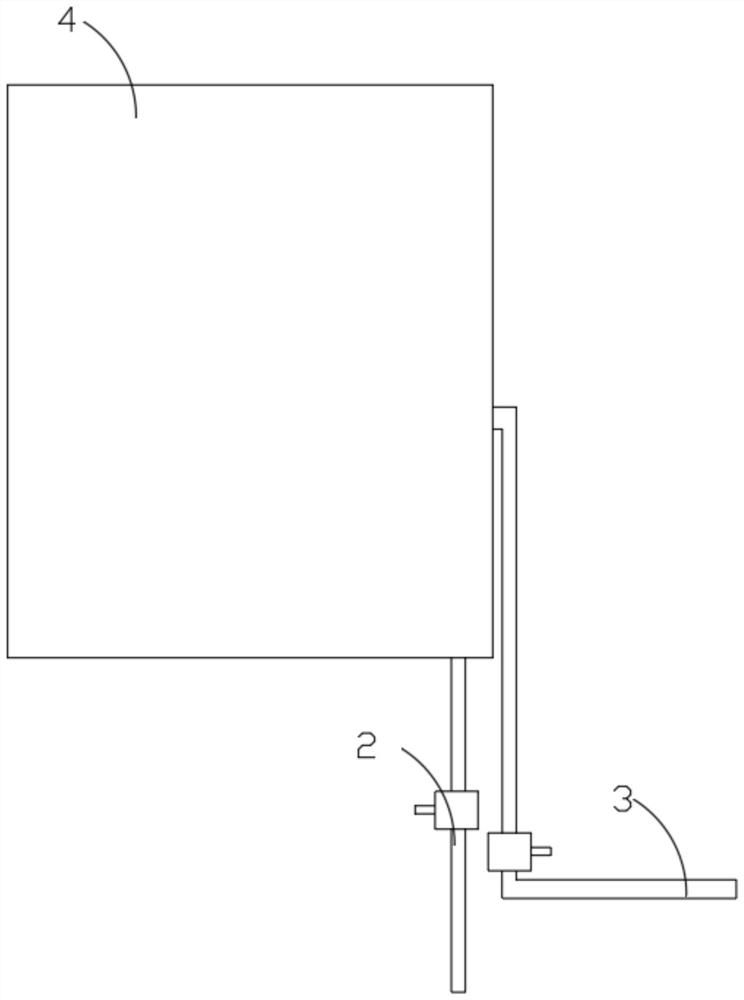

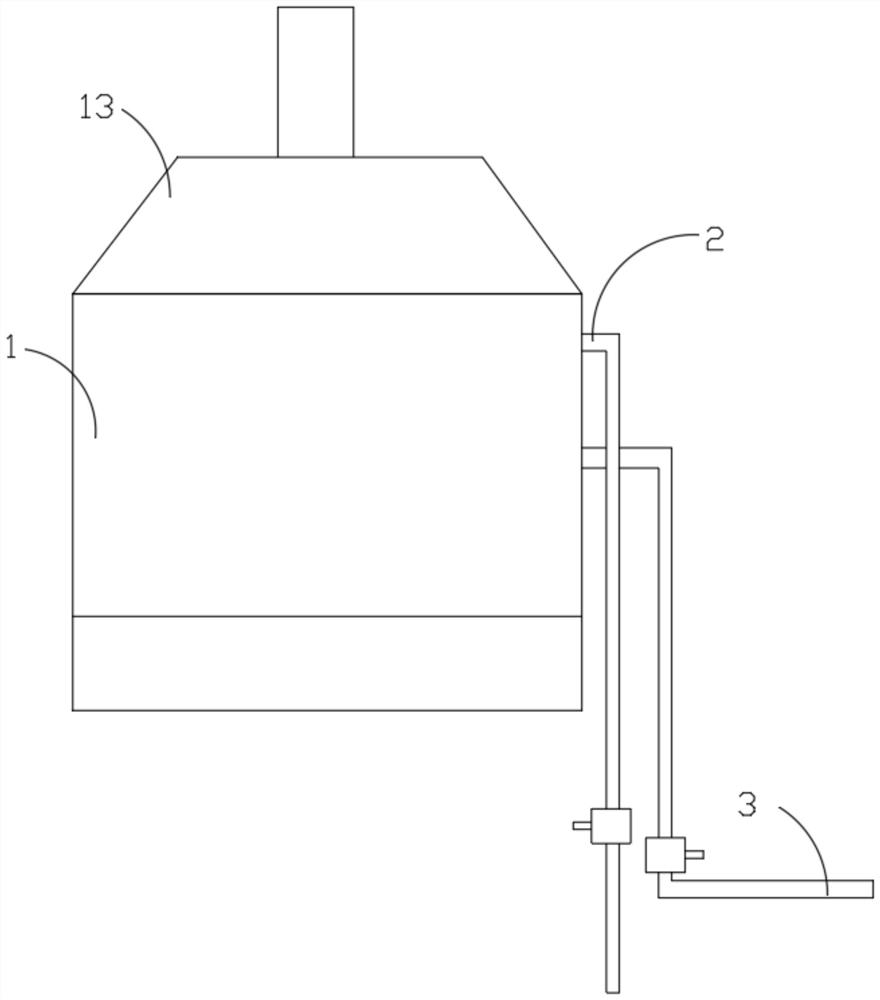

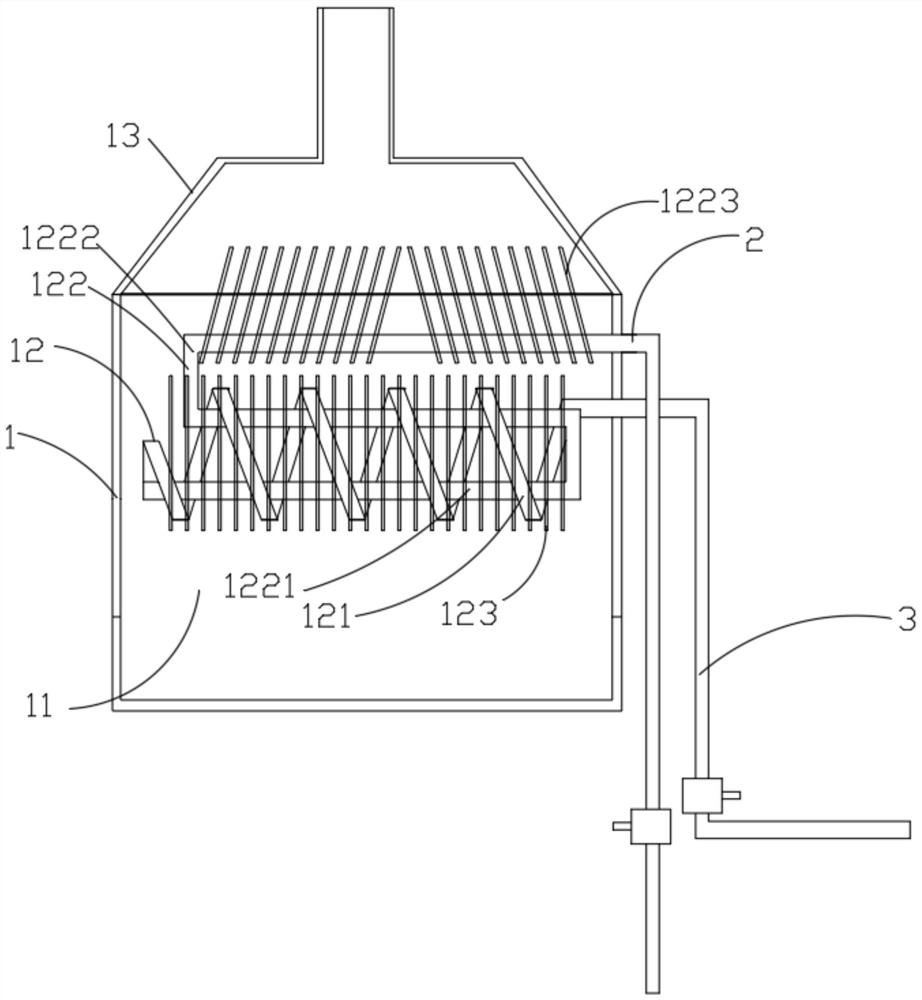

[0023] The embodiment of the invention discloses a heat exchange structure for a water heater, such as Figure 1-3 As shown, it includes a combustion chamber 1, a water inlet pipe 2, an outlet pipe 3, and an insulated housing 4. The combustion chamber 1 is installed in the insulated housing 4, and the combustion chamber 1 is provided with a combustion chamber 11. The combustion chamber 11 is provided with a heat exchange mechanism 12 on the top, and the heat exchange mechanism 12 includes a first heat exchange pipe 121, a second heat exchange pipe 122, and several heat conduction fins 123, and the first heat exchange pipe 121 extends along the horizontal direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com