Cloth guide device and air-liquid cloth dyeing machine comprising same

A cloth guiding device and cloth dyeing machine technology, which is applied in the field of dyeing and finishing technology, and can solve problems such as difficult dredging of cloth jams, fabric scratches, and air-liquid dyeing machine airtightness effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The cloth guiding device that present embodiment provides, specific scheme is as follows:

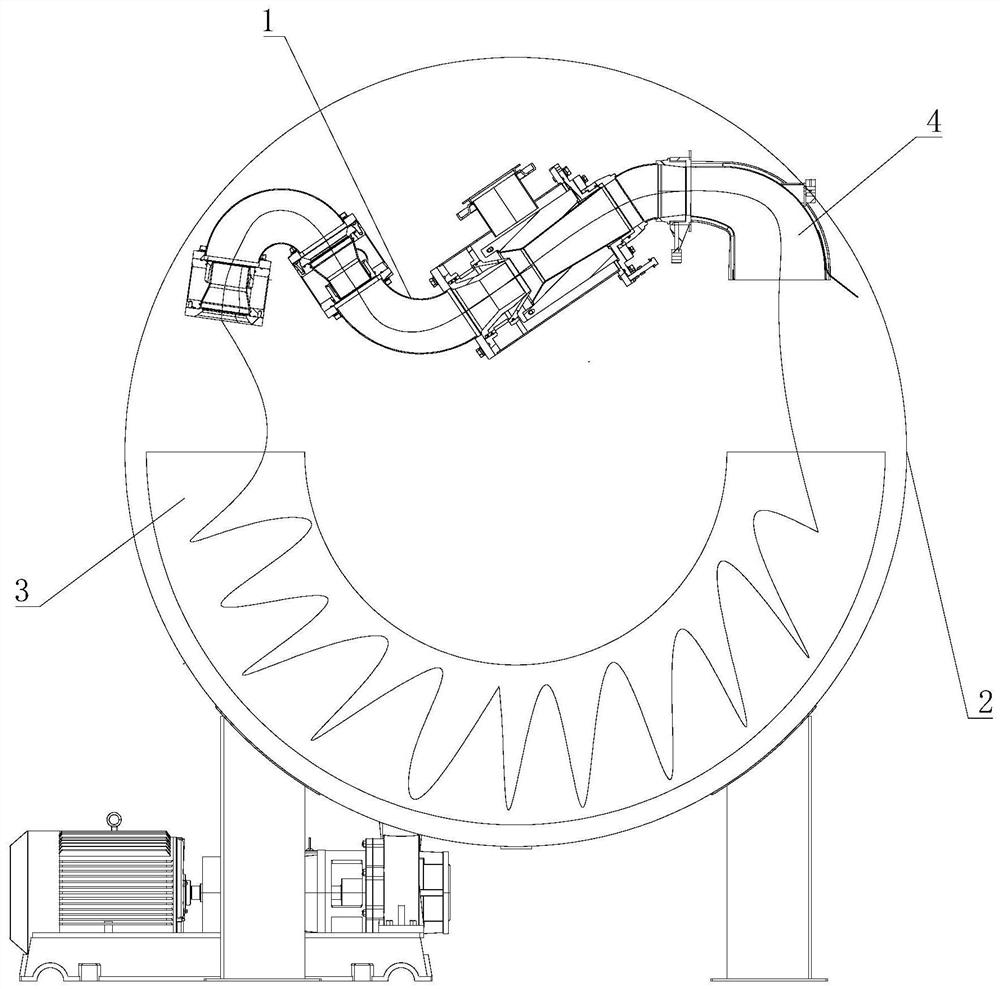

[0016] Such as figure 1 As shown, the cloth guiding device 1 includes a first liquid flow nozzle 11, a first elbow 12, a second liquid flow nozzle 13, a second elbow 14, a third liquid flow nozzle 15 and an air nozzle 16, and the first liquid flow nozzle 11. The first elbow 12 , the second liquid flow nozzle 13 , the second elbow 14 , the third liquid flow nozzle 15 and the air nozzle 16 are connected in sequence and distributed in an S shape. The fabric passes through the first liquid flow nozzle 11, the first curved pipe 12, the second liquid flow nozzle 13, the second curved pipe 14, the third liquid flow nozzle 15 and the air nozzle 16 and then enters the next mechanism, and the fabric does not need a cloth lifting roller. Multiple potentials are provided through multiple nozzles to realize low-tension fabric guiding and avoid damage to fabrics when the fabric lifting roller...

Embodiment 2

[0019] Such as figure 2 As shown, this embodiment provides a gas-liquid dyeing machine, including a cylinder body 2, a cloth storage tank 3 built in the cylinder body 2, and the cloth guide device 1 in Embodiment 1, and the cloth guide device 1 is built in the cylinder body 2 , and fixedly located above the cloth storage tank 3 . In this embodiment, the cloth outlet of the cloth storage tank 3 is aligned with the first liquid flow nozzle 11, and the wind nozzle 16 is movably connected with the cloth bucket 4, and the cloth outlet of the cloth storage tank 4 is aligned with the cloth drop opening of the cloth storage tank 3 .

[0020] In this embodiment, during a single cycle of the fabric, the first liquid flow nozzle 11 , the second liquid flow nozzle 13 , the third liquid flow nozzle 15 and the wind nozzle 16 provide multiple powers to guide the fabric. The dye liquor sprayed by the first liquid flow nozzle 11 and the second liquid flow nozzle 13 penetrates and exhausts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com