Cloth processing technology

A processing technology and fabric technology, applied in the field of fabric processing technology, can solve the problems of aggravating the wrinkle degree of the fabric, increasing the milling time and the difficulty of milling, and achieve the effect of reducing the probability of wrinkling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

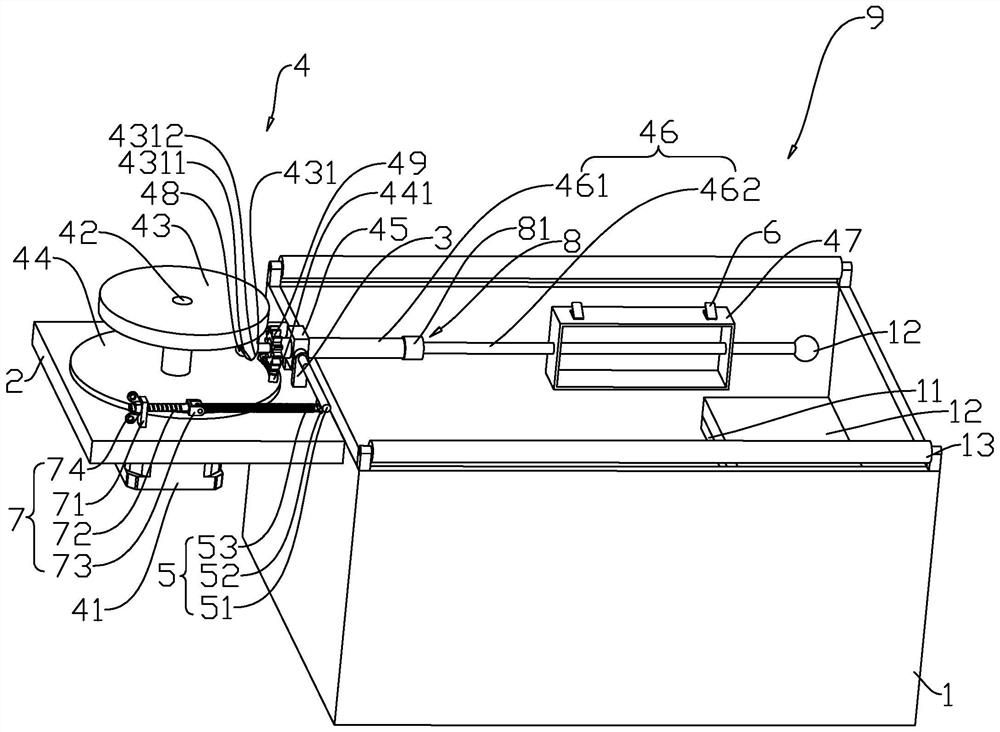

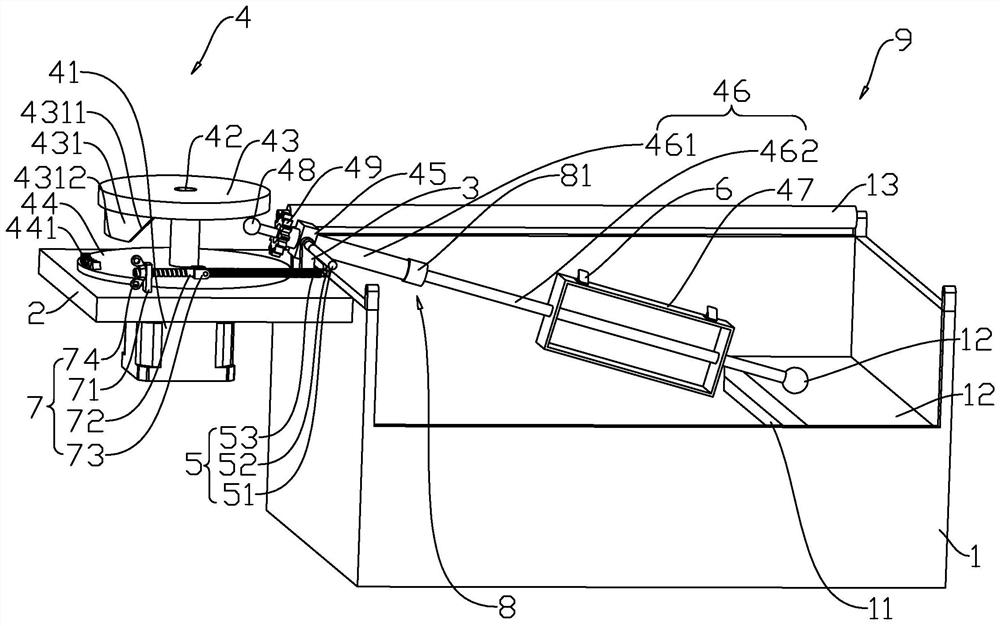

[0041] The following is attached Figure 1-4 The application is described in further detail.

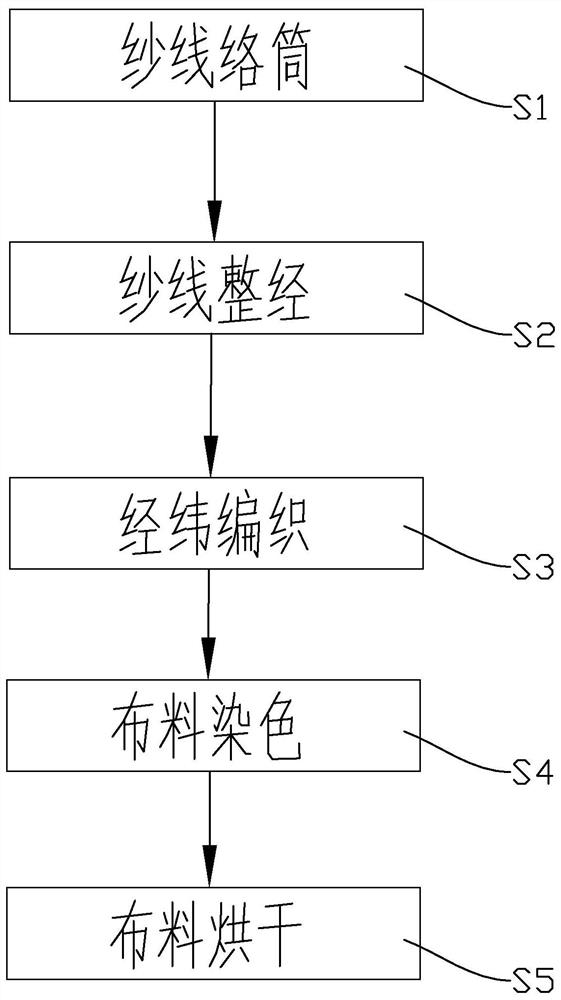

[0042] The embodiment of the present application discloses a fabric processing technology. refer to figure 1 , the fabric processing technology includes the following process steps:

[0043] S1. Yarn winding: rewind the finished white bobbin by winding machine to make bobbins;

[0044] S2. Yarn warping: use a warping machine to wind the cheese in parallel on the warp beam, and pass every two warp threads on the warp beam into a heald eye and reed, so that the processed warp has tension;

[0045] S3. Warp and weft weaving: Use a large rapier machine to weave the weft and warp in a criss-cross pattern, and weave white gray cloth in the way that every two warps and one weft are interlaced up and down;

[0046] S4. Cloth dyeing: put the woven gray cloth into a dyeing vat equipped with dyeing solution, and the dyeing vat is provided with a dyeing mechanism for repeatedly immersing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com