Vertical annealing device for enameled wire

An annealing device and enameled wire technology, applied in the furnace type, furnace, heat treatment furnace and other directions, can solve the problems of easy oxidation of bare wires, affecting annealing effect, affecting enameled wire painting and baking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

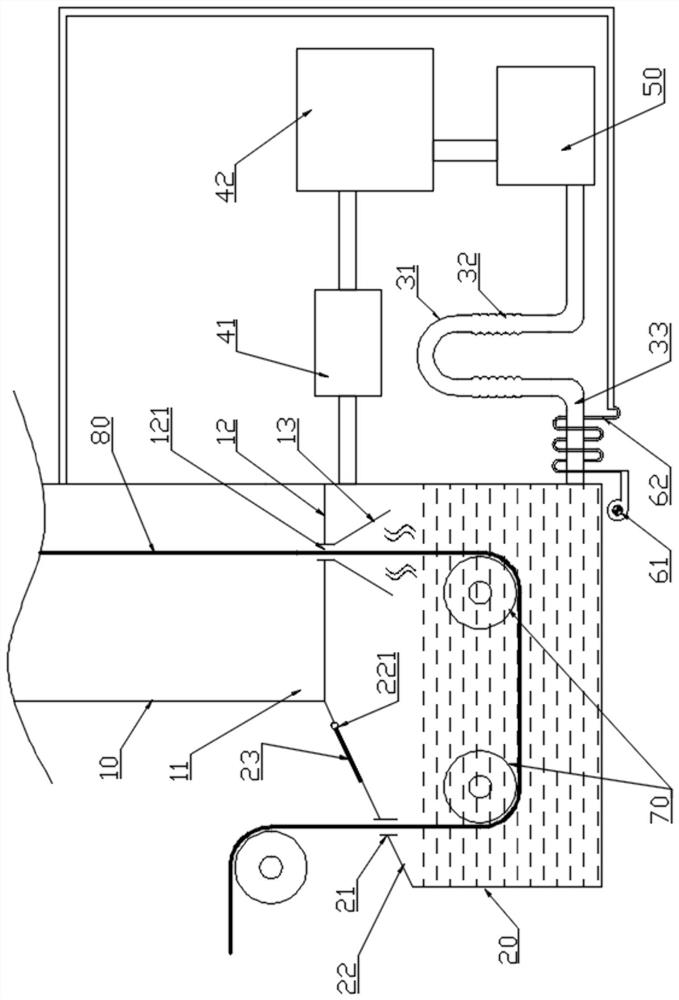

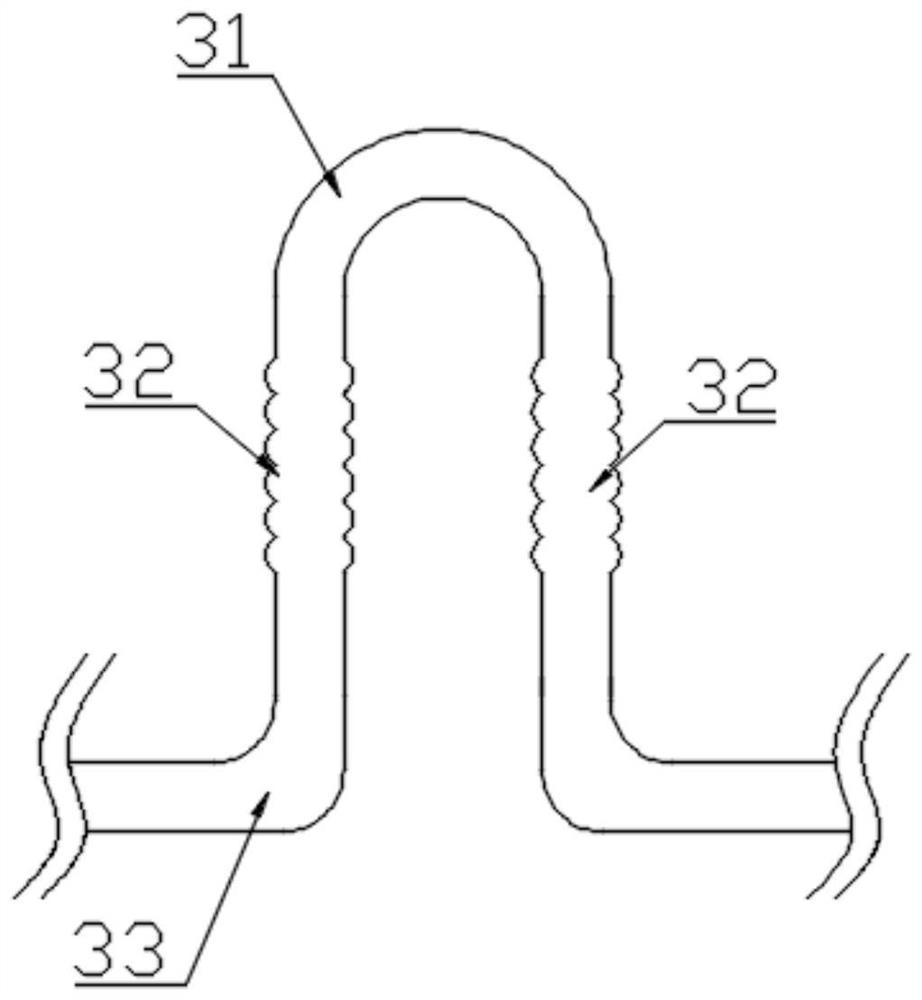

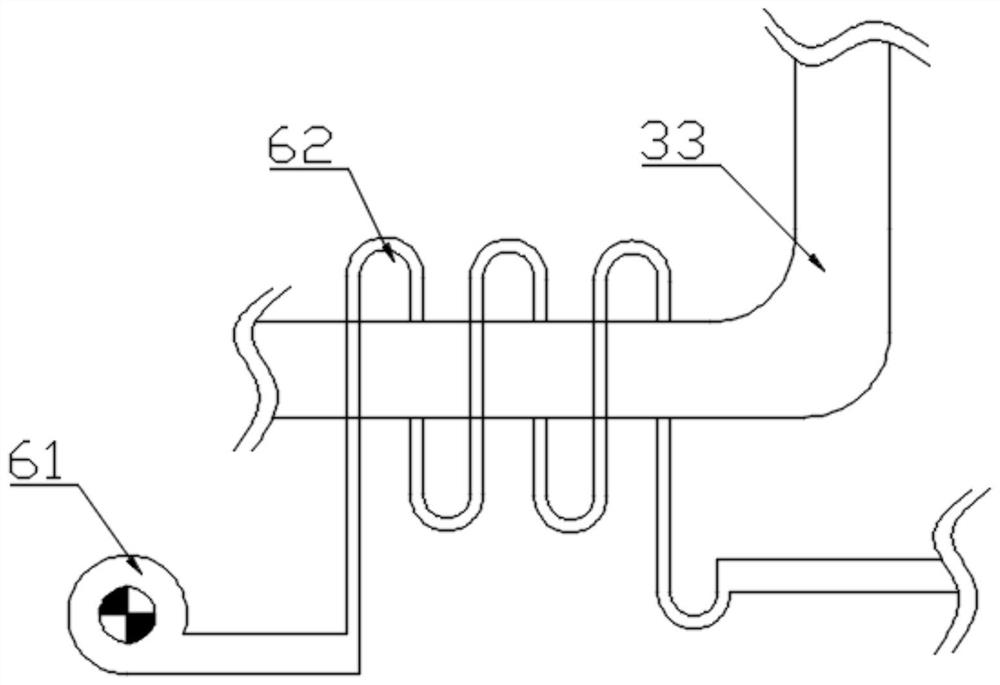

[0034] see Figure 1 to Figure 4 , a vertical enameled wire annealing device of the present embodiment includes an annealing furnace 10, several guide plates 13, a cooling water tank 20, a U-shaped pipe 31, a water pump 41, a filter 50, a blower 61, a heat exchange tube 62 and two coils Line drum 70.

[0035] Specifically, the annealing furnace 10 is arranged vertically; the entrance of the annealing furnace 10 is at the top, and the outlet 11 of the annealing furnace is at the bottom; Enter the cooling water tank 20;

[0036] More specifically, the outlet 11 of the annealing furnace is provided with a baffle 12; the baffle 12 is provided with a through hole 121 for the bare wire 80 to pass through;

[0037] More specifically, each guide plate 13 is obliquely arranged at the bottom of the baffle plate 12 ; the bare wire 80 generates steam after contacting the cooling water in the cooling water tank 20 , and the guide plate 13 is used to guide the steam to the through hole 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com