Combined processing method of petroleum hydrocarbon and polycyclic aromatic hydrocarbon-rich material

A technology for combined processing of polycyclic aromatic hydrocarbons, which is applied in the field of combined processing of petroleum hydrocarbons and materials rich in polycyclic aromatic hydrocarbons, and can solve the problems of increased dry gas and coke yields in catalytic cracking units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Reagents, Instruments and Tests

[0057] Unless otherwise specified, the reagents used in the present invention are all analytically pure, and all reagents used are commercially available, for example, purchased from Bailingwei and Sinopharm Group.

[0058] In the following examples, preparation examples and comparative examples, the assay method of B acid acidity is as follows:

[0059] The FTS3000 Fourier transform infrared spectrometer produced by the American BIO-RAD company was used.

[0060] Test conditions: After the sample is pressed into a tablet, it is placed in the in-situ cell of the infrared spectrometer and sealed, and it is vacuumed at 350 ° C to 10 -3 Pa, keep it for 1h to desorb the gas molecules on the surface of the sample, and cool to room temperature. Introduce pyridine vapor with a pressure of 2.67Pa into the in-situ cell, and after equilibrating for 30 minutes, raise the temperature to 200°C, and then evacuate to 10°C again. -3 Pa, keep for 30m...

preparation example 1

[0062] Preparation Example 1 Preparation of Modified Aluminum Oxide

[0063] Take 100.0 grams of pseudo-boehmite (Changling Catalyst Branch), impregnate with an aqueous solution containing 5.5 g of ammonium fluoride for 3 hours, dry at 150°C for 3 hours, and roast at 550°C for 3 hours in an air atmosphere to obtain a modified compound containing F. alumina.

preparation example 2

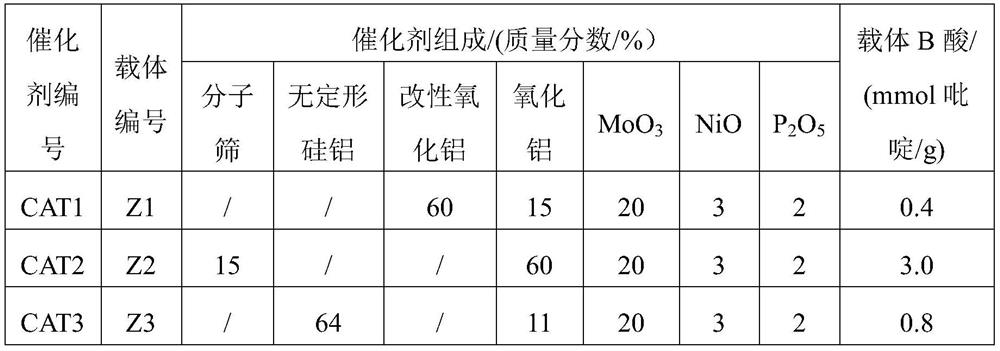

[0064] The preparation of preparation example 2 catalyst CAT1

[0065] Get 50.0 grams of pseudo-boehmite (Changling Catalyst Branch Company, dry base 0.71) and mix with 191.9 grams of modified alumina (preparation example 1), and extrude into a clover-shaped strip whose circumscribed circle diameter is 1.6 mm, wet The strips were dried at 150°C for 3 hours and calcined at 550°C for 3 hours to obtain carrier Z1. The B acid content of carrier Z1 is shown in Table 1.

[0066] Take 100.0 g of carrier Z1 and use 95 ml of MoO 3 280.7 g / L, NiO 42.1 g / L, P 2 o 5 28.1 g / L, citric acid 45.5 g / L nickel, molybdenum complex solution impregnated for 4 hours, dried at 150 ° C for 3 hours to obtain the catalyst CAT1. The content of metal oxides on the catalyst CAT1 is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com