T16 cage structure epoxy phenyl silsesquioxane and preparation method thereof

A technology of epoxy phenyl and silsesquioxane, which is applied in the field of organic-inorganic hybrid material science, can solve problems such as unsuitable for expanding production and application, and achieve easy control, good thermal stability, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

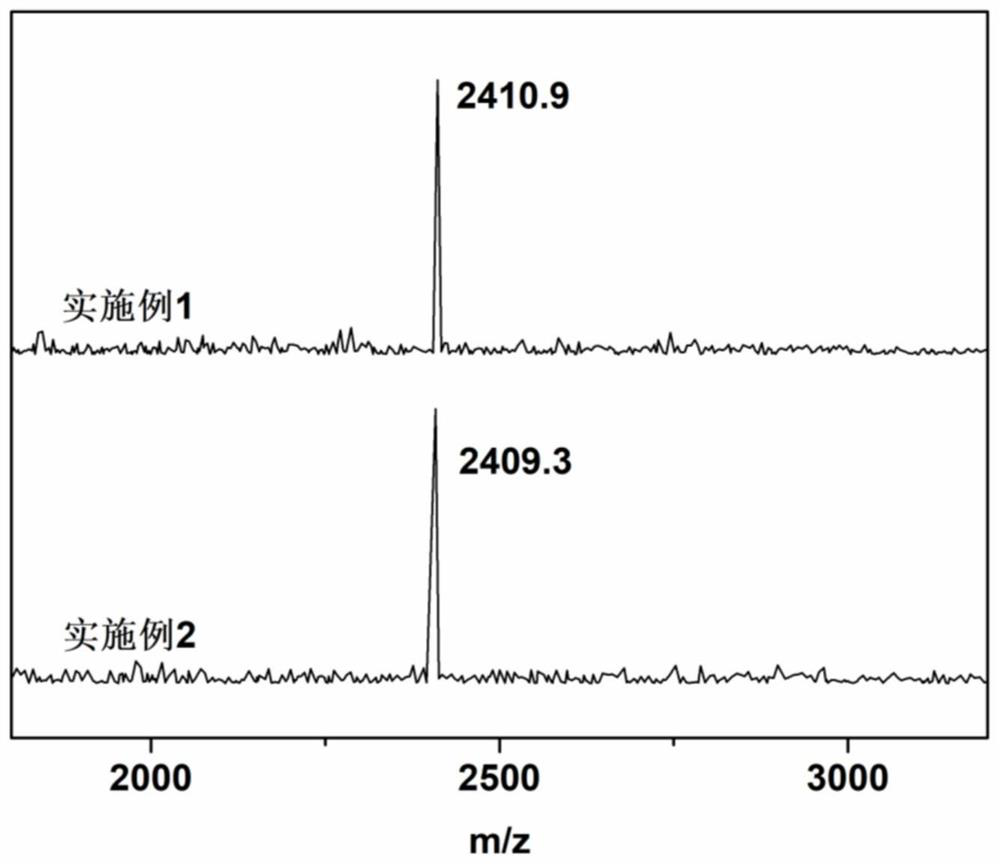

Embodiment 1

[0022] 1) In a 2L three-neck flask equipped with a magnetic stirrer, a condensing reflux device, a constant pressure dropping funnel and a constant temperature device, add 600ml of dichloromethane, 54.1g of phenyltriethoxysilane and 108.1g of 2-(3,4 -Epoxycyclohexane) ethyltriethoxysilane, stirred and heated up to 25°C, added 48ml of 0.015g / ml NaOH lye, maintained the reaction temperature at 40°C, stirred and refluxed for 12 hours to obtain a condensation reaction solution .

[0023] 2) Add an appropriate amount of 0.1mol / L hydrochloric acid solution dropwise to make the reaction solution neutral, wash with deionized water, add anhydrous sodium sulfate to remove residual moisture in the organic phase, filter, take the filtrate and spin evaporate at 40°C to remove the solvent dichloromethane, and dry the product at 80° C. for 12 hours to obtain a colorless and transparent viscous liquid T16 cage structure epoxy phenyl silsesquioxane.

[0024] figure 1 It is the FT-IR spectrum...

Embodiment 2

[0030] 1) In a 2L three-necked flask equipped with a magnetic stirrer, a condensing reflux device, a constant pressure dropping funnel and a constant temperature device, add 1200ml of methylene chloride, 108.2g of phenyltriethoxysilane and 216.3g of 2-(3,4 -Epoxycyclohexane) ethyltriethoxysilane, stirred and heated up to 25°C, added 96ml of 0.015g / ml NaOH lye, maintained the reaction temperature at 40°C, stirred and refluxed for 18 hours to obtain a condensation reaction solution .

[0031] 2) Add an appropriate amount of 0.1mol / L hydrochloric acid solution dropwise to make the reaction solution neutral, wash with deionized water, add anhydrous sodium sulfate to remove residual moisture in the organic phase, filter, take the filtrate and spin evaporate at 40°C to remove the solvent dichloromethane, and dry the product at 90° C. for 12 hours to obtain a colorless and transparent viscous liquid T16 cage structure epoxy phenyl silsesquioxane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com