Method for reducing methane gas emission in cow dung composting process

A technology of methane gas and cow dung, which is applied in the direction of fertilization equipment, fertilizer mixture, fertilizer treatment control, etc., to reduce the bulk density, reduce methane emissions, and improve the quality of compost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

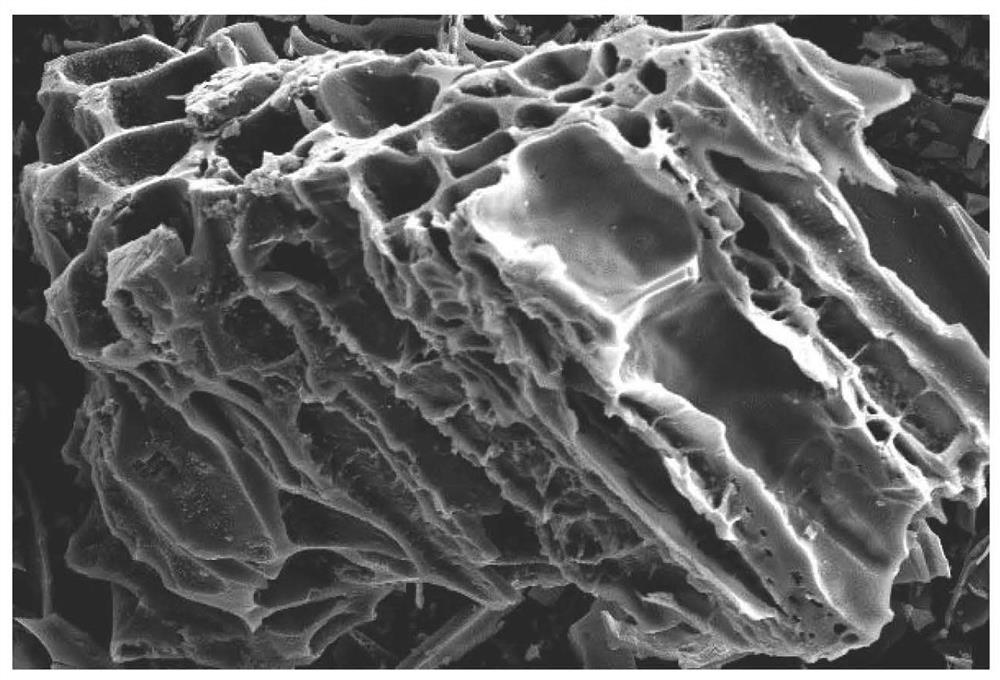

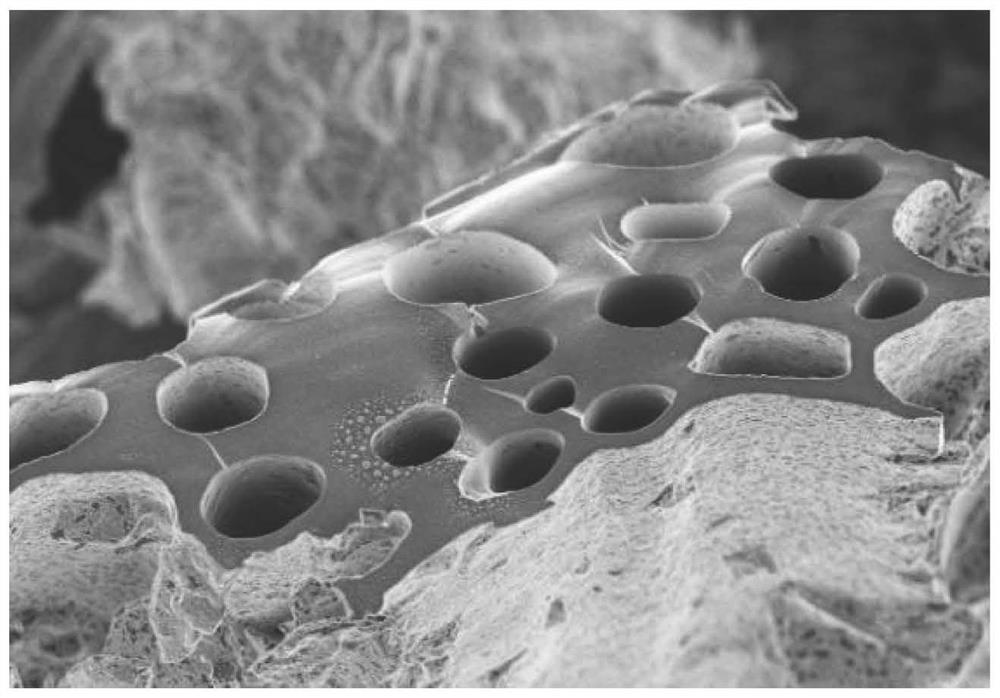

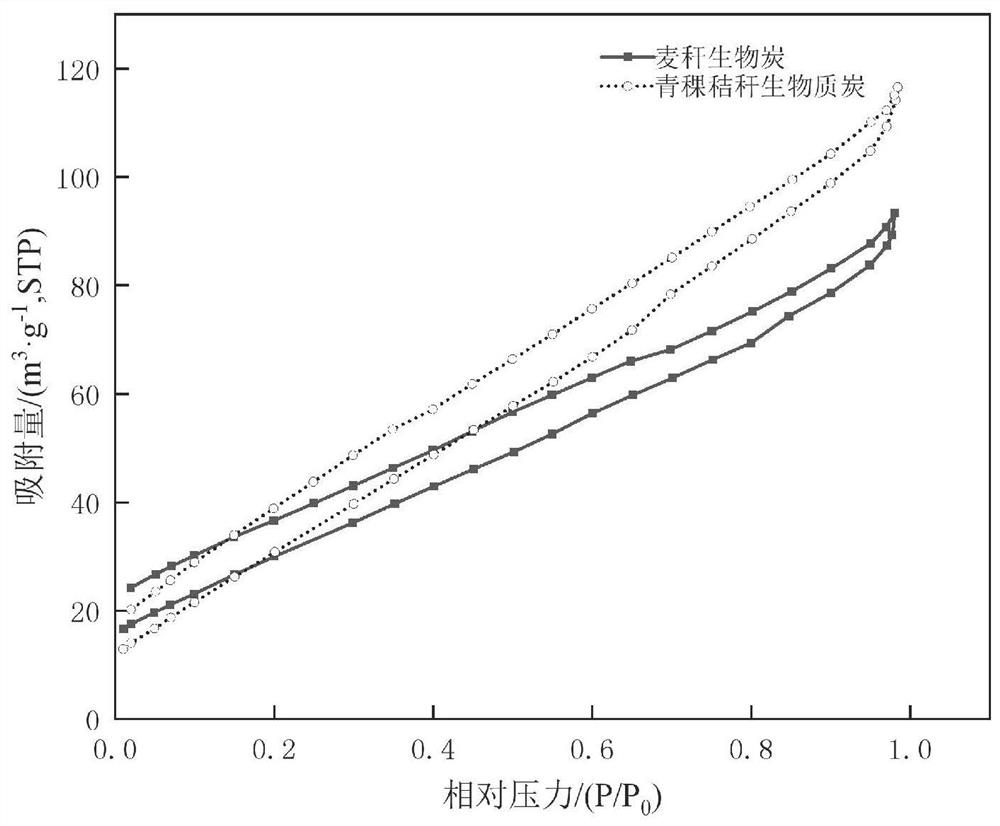

[0039] (1) Preparation of highland barley straw biochar: dry the highland barley straw until the water content is ≤3%, crush it and pass it through an 80-mesh sieve; heat it to 400°C at a heating rate of 5°C / min in an anoxic environment, and carbonize it for 2 hours. After completion, the anoxic environment was maintained for 1 h, and the biochar was collected by cooling; the biochar was ground to 20 mesh, and 1 mol L -1Wash with HCl solution to remove ash, filter, rinse with deionized water to pH 7.0, and dry.

[0040] (2) Compost aerobic fermentation: use cow dung and straw as the basic material, mix according to the carbon-nitrogen ratio of 25, and control the water content to 60%; use the mass ratio of basic material and biochar as 9:1, add highland barley straw biochar ; The fermentation temperature is controlled at 35°C, and the fermentation lasts for 33 days until the compost becomes decomposed.

Embodiment 2

[0042] (1) Preparation of wheat straw biochar: Dry the wheat straw until the water content is ≤3%, crush it and pass it through a 60-mesh sieve; heat it to 300°C at a heating rate of 5°C / min in an anoxic environment, and carbonize it for 3 hours. After completion, the anoxic environment was maintained for 1 h, and the biochar was collected by cooling; the biochar was ground to 10 mesh, and 1 mol L -1 Wash with HCl solution to remove ash, rinse with deionized water to pH 7.3 after filtration, and dry.

[0043] (2) Compost aerobic fermentation: use cow dung and straw as the basic material, mix according to the carbon-to-nitrogen ratio of 30, and control the water content to 63%; the mass ratio of the basic material to biochar is 8:1, and add wheat straw biochar; The fermentation temperature is controlled at 33°C, and the fermentation lasts for 42 days until the compost is fully decomposed.

Embodiment 3

[0045] (1) Preparation of highland barley and wheat straw biochar: dry the highland barley and wheat straw to a moisture content of ≤3%, crush them and pass through a 100-mesh sieve; heat them to 500°C at a heating rate of 10°C / min in an anoxic environment, and carbonize After the carbonization process was completed, the anoxic environment was maintained for 1 h, and the biochar was collected by cooling; the biochar was ground to 30 mesh, and 1mol L -1 Wash with HCl solution to remove ash, rinse with deionized water to pH 7.5 after filtration, and dry.

[0046] (2) Compost aerobic fermentation: use cow dung and straw as basic materials, mix them at a carbon-to-nitrogen ratio of 35, and control the water content to 65%; take the mass ratio of basic materials and biochar as 10:1, add highland barley straw biochar and Wheat straw biochar mixture; the fermentation temperature is controlled at 40°C, and the fermentation lasts for 37 days until the compost is mature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com