Lithium cobalt oxide positive electrode material and preparation method thereof

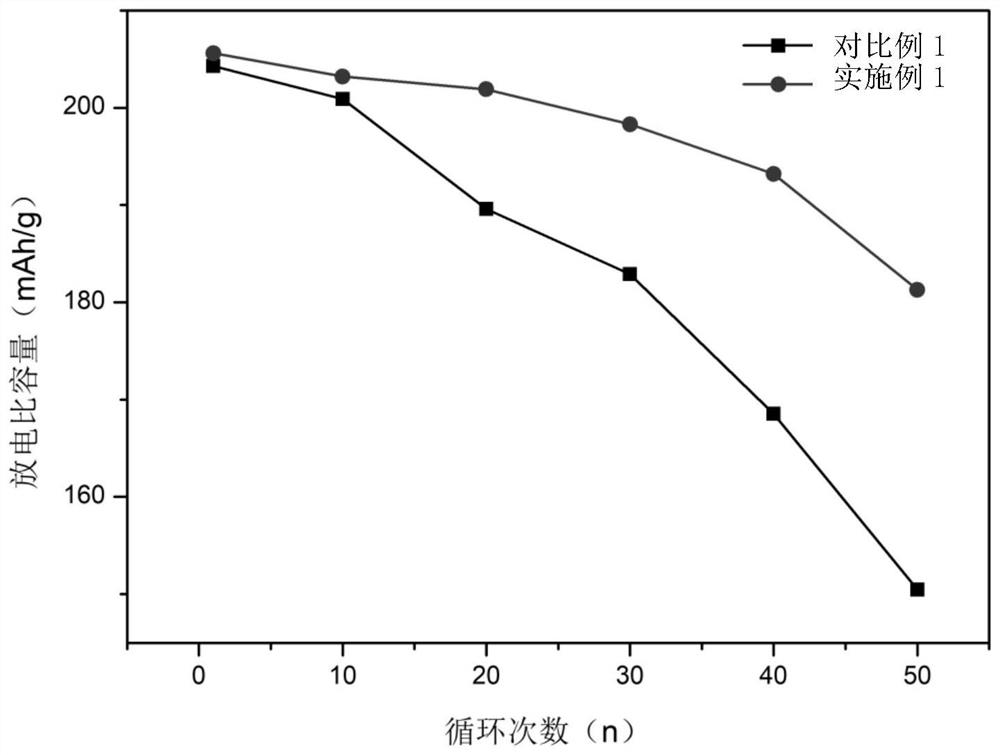

A positive electrode material, lithium cobalt oxide technology, applied in chemical instruments and methods, battery electrodes, cobalt compounds, etc., can solve problems such as poor cycle performance, and achieve the effects of increasing service life, improving cycle performance, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] One aspect of the present invention provides a method for preparing a lithium cobalt oxide positive electrode material, the preparation method comprising the following steps:

[0030] Step 1. Mix the cobalt source and the lithium source to perform a synthesis to obtain product A.

[0031] According to the present invention, in step 1, the cobalt source is a cobalt-containing compound, preferably selected from one or more of tricobalt tetroxide, cobalt hydroxide, cobalt carbonate, cobalt nitrate, and cobalt chloride, more preferably tricobalt tetroxide or cobalt carbonate, for example tricobalt tetroxide.

[0032] According to the present invention, in step 1, the lithium source is a lithium-containing compound, preferably one or more of lithium carbonate, lithium nitrate, lithium hydroxide, lithium oxalate, lithium acetate, lithium oxide, lithium chloride, more preferably Lithium carbonate or lithium hydroxide, such as lithium carbonate.

[0033] According to the pres...

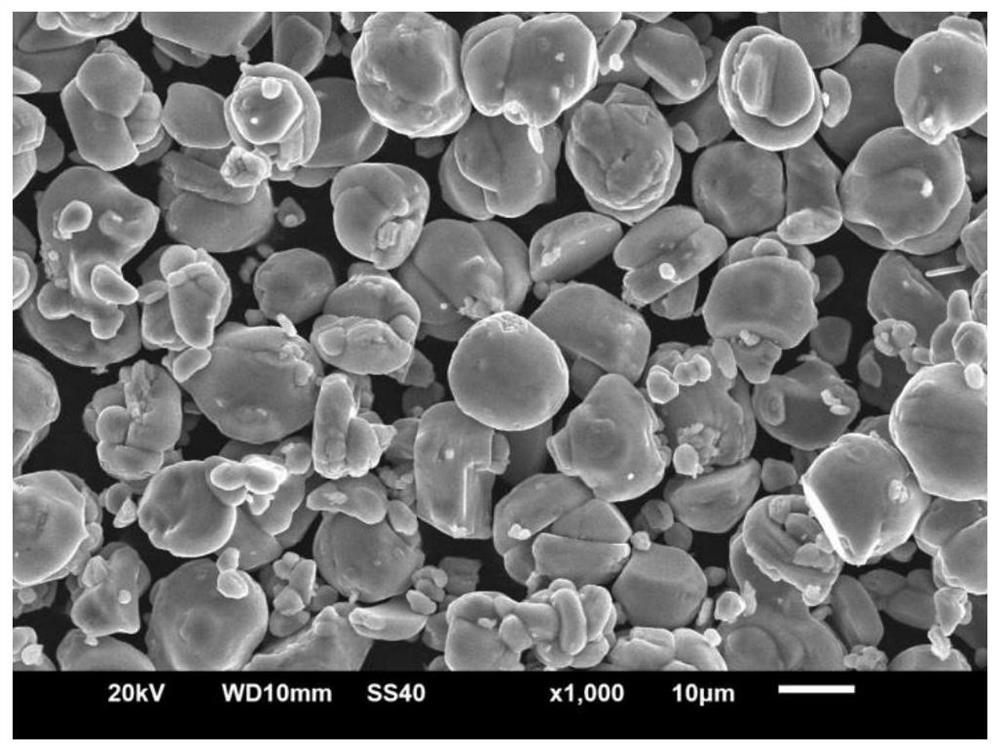

Embodiment 1

[0068] Weigh dry 400g of cobalt tetroxide and 186.8g of lithium carbonate, add them to a high-speed mixer, mix at a high speed of 1500r / min for 80s, then add them to a planetary ball mill for uniform mixing, and ball mill for 3 hours at a speed of 850r / min. After the mixing is completed, the mixture is put into a muffle furnace for a synthesis, and is calcined at a high temperature of 950°C for 8 hours to obtain the product A;

[0069] Take 50g of product A and add it to 400g of absolute ethanol, and ultrasonically treat it to obtain a suspension;

[0070] Move the suspension into the digestion tank of the high-throughput microwave digestion, extraction and synthesis workstation, and add an equal mass of absolute ethanol to the main control tank. The liquid level does not exceed two-thirds of the reaction tank. 300°C, the treatment time is 30min, after the treatment is completed, it is removed from the workstation after cooling to obtain the product B.

[0071] The product B ...

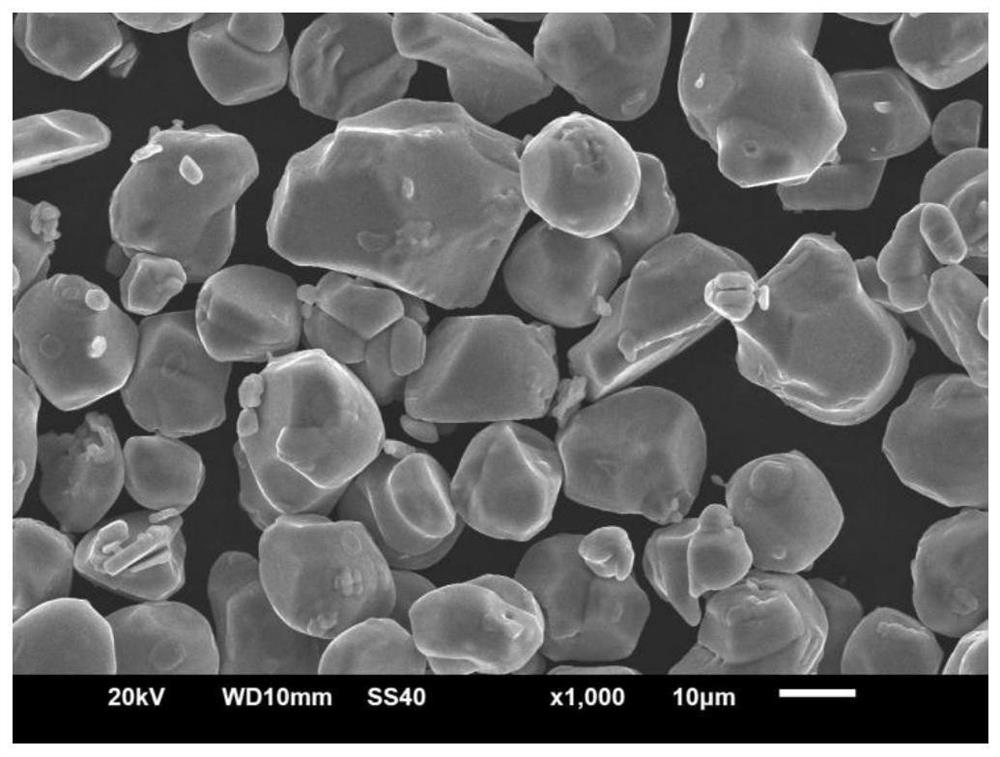

Embodiment 2

[0074] Weigh dry 400g of cobalt tetroxide and 186.8g of lithium carbonate, add them to a high-speed mixer, mix at a high speed of 1600r / min for 70s, then add them to a planetary ball mill for uniform mixing, and ball mill for 3 hours at a speed of 850r / min. After the mixing is completed, the mixture is put into a muffle furnace for a synthesis, and is calcined at a high temperature of 950°C for 8 hours to obtain the product A;

[0075] Take 50g of product A and add it to 400g of absolute ethanol, and ultrasonically treat it to obtain a suspension;

[0076] Move the suspension into the digestion tank of the high-throughput microwave digestion, extraction and synthesis workstation, and add an equal mass of absolute ethanol to the main control tank. The liquid level does not exceed two-thirds of the reaction tank. 300°C, the treatment time is 20min, after the treatment is completed, it is cooled and then removed from the workstation to obtain the product B.

[0077] The product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com