Electric circular saw

A technology of electric circular saws and saw blades, applied in circular saws, portable motorized circular saws, sawing equipment, etc., can solve the problems of poor heat dissipation effect of power boards, complex cooling air path design, etc., to increase the effective heat dissipation surface area, Improve heat dissipation efficiency and ensure heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

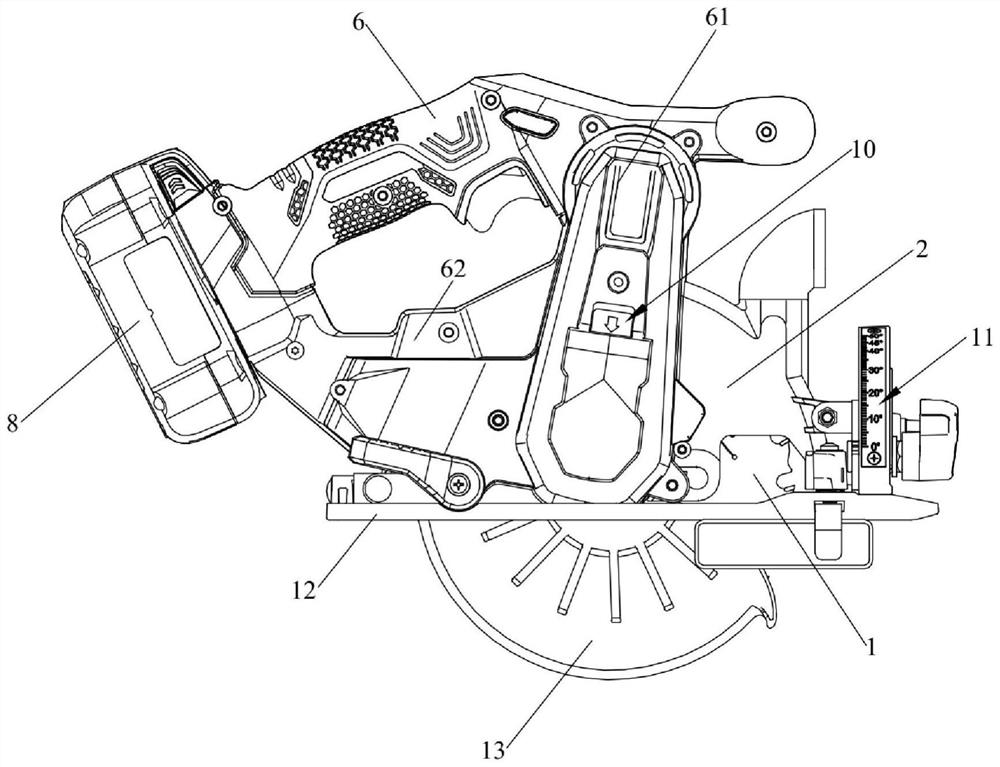

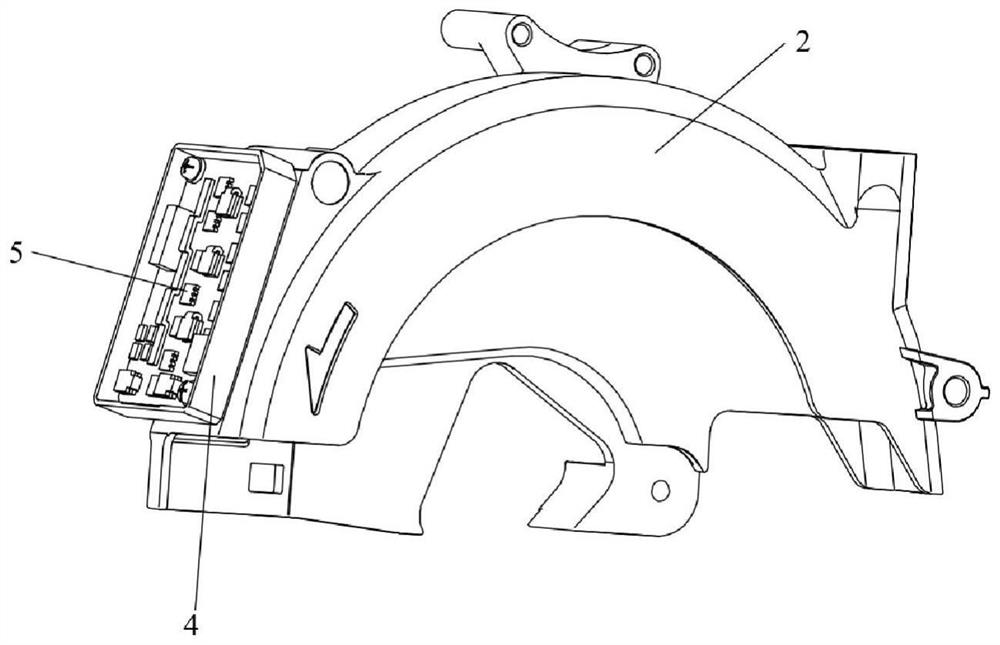

[0058] like Figure 1-Figure 3 As shown, this embodiment provides an electric circular saw, including a saw blade 1 , a fixed guard 2 , a motor 3 , a heat sink 4 , a power board 5 and a casing 6 . Specifically, the casing 6 includes a grip portion for the user to grip. The motor 3 includes an output shaft rotating around the first axis, the output shaft is connected to and drives the saw blade 1 ; The cooling element 4 is arranged on the fixed shield 2, and the casing 6 includes a first housing part 61 and a second containing part 62 arranged at both ends of the casing 6, the motor 3 is arranged in the first containing part 61, and the cooling element 4 is arranged on the Inside the second housing portion 62 . The power board 5 is disposed on the heat sink 4 for controlling the output power of the motor 3 .

[0059]In the electric circular saw provided in this embodiment, the radiator 4 is arranged on the fixed shield 2 , and the fixed shield 2 and the radiator 4 are integr...

Embodiment 2

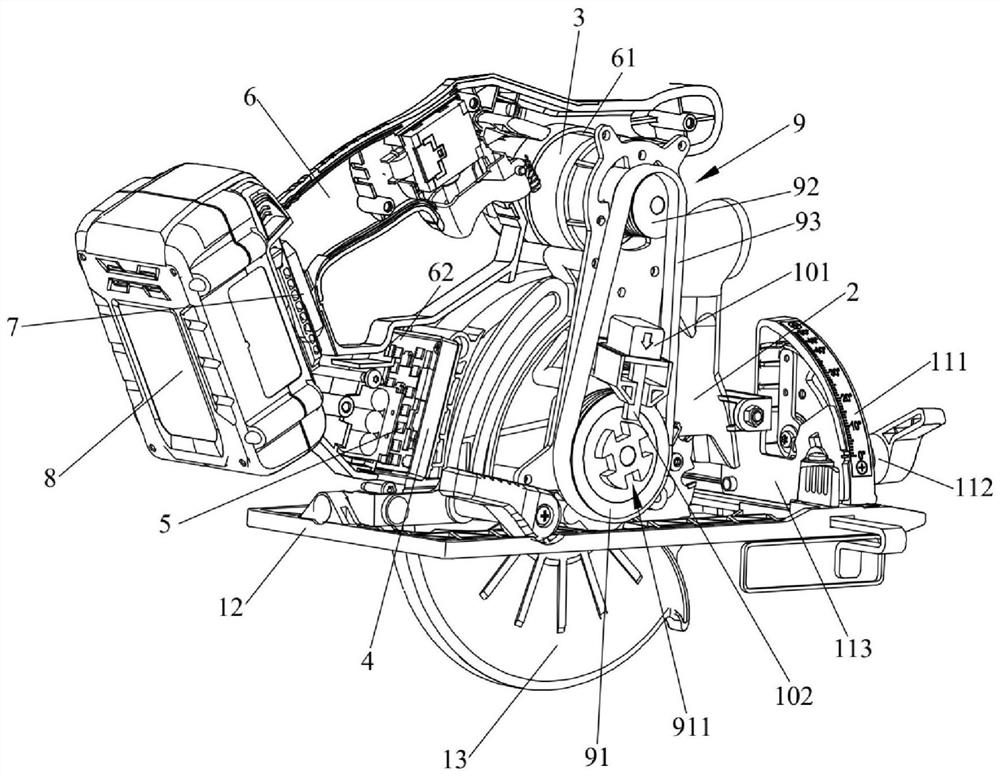

[0072] like Figure 4-Figure 6 As shown, this embodiment provides another electric circular saw. The difference between this embodiment and Embodiment 1 is that the installation positions of the motor 3A and the radiator 4A are different. Correspondingly, the extension of the transmission belt 93A relative to the fixed guard 2A The direction, and the position of the locking assembly 10A relative to the fixed shield 2A have also been adjusted. Specifically, the fixed shield 2A is fixedly connected to the casing 6A, the motor 3A is fixedly arranged in the first accommodation portion 61A of the casing 6A, and is located behind the fixed shield 2A, and the heat sink 4A is arranged on the second side of the casing 6A. Inside the housing portion 62A, it is located on the upper side of the fixed shield 2A. The cooling air of the fan flows directly from one side of the motor 3A to the other side of the motor 3A, and the cooling air path of the fan is outside the projection of the fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com