A centrifugal supplementary oil supply device and method based on micropore oil supply

An oil supply device and centrifugal technology, applied in chemical instruments and methods, solid separation, classification, etc., can solve the problems of poor delay effect, low effective oil supply rate, high oil supply rate, etc., and achieve a basic oil supply rate Consistent, meet the long life requirements, the effect of stable oil supply rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

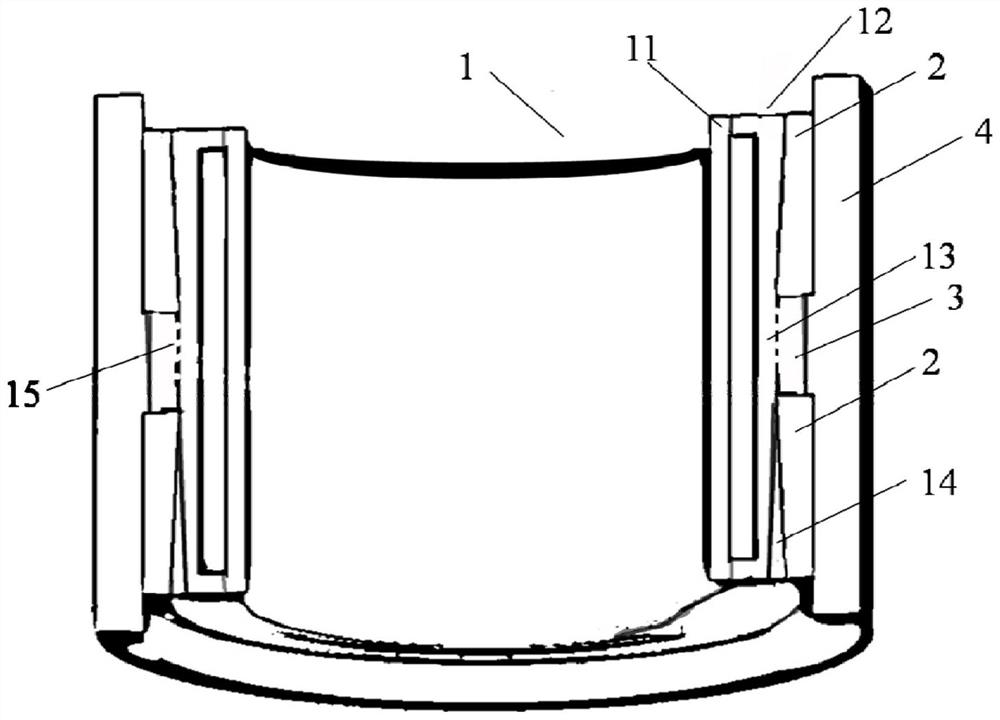

[0036] The present invention will be further described below by describing a preferred specific embodiment in detail with reference to the accompanying drawings.

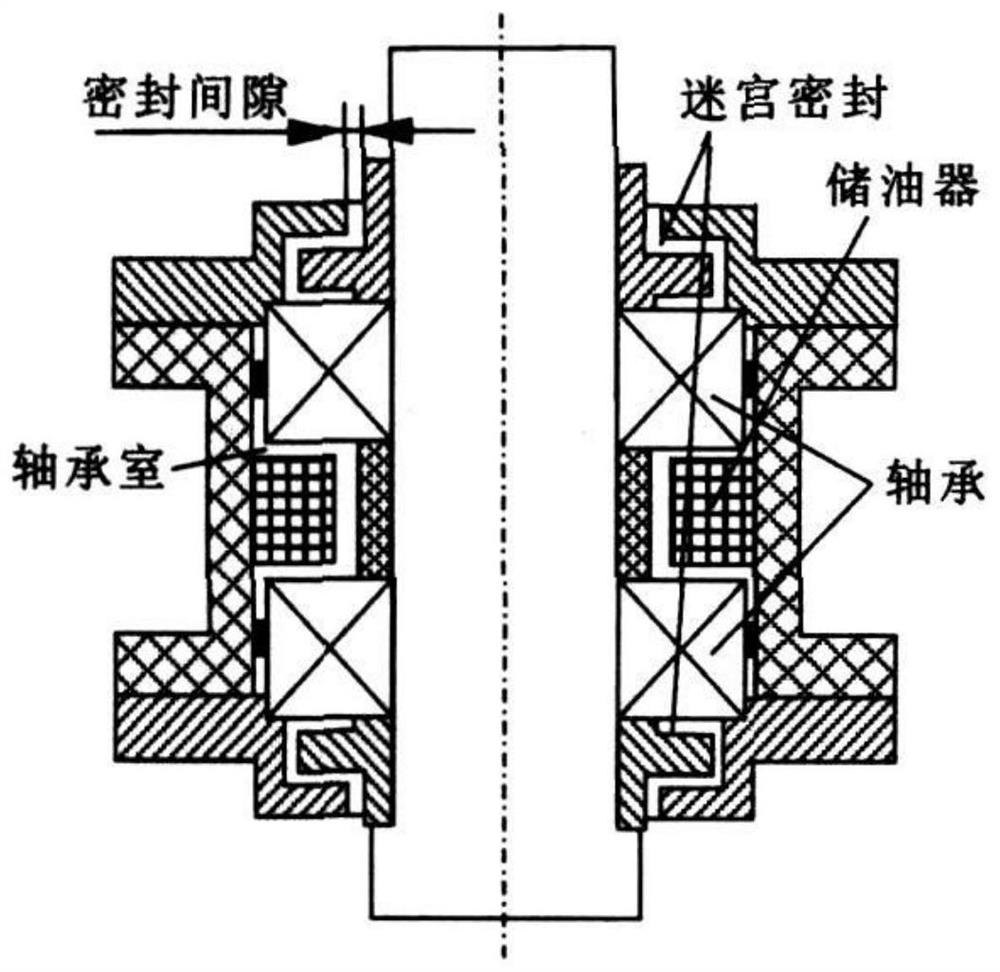

[0037] like image 3 As shown, it is a centrifugal supplementary oil supply device based on micropore oil supply of the present invention, and the positional relationship between the centrifugal supplementary oil supply device and the bearing assembly is the same as that of the bearing assembly. figure 1 The two positions in the bearing system shown are similar.

[0038] The centrifugal supplementary oil supply device based on micropore oil supply of the present invention (may be simply referred to as the bearing centrifugal supplementary oil supply device) comprises an oil reservoir 1 and a pair of wedge-shaped delay rings 2 . In this embodiment, the oil reservoir 1 contains lubricating oil. Wherein, each wedge-shaped delay ring 2 is arranged around the outer surface of the oil reservoir 1, the outer side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com