Vacuum arc-extinguishing chamber with composite contact structure

A vacuum interrupter and composite contact technology, applied in high-voltage air circuit breakers, electrical components, electrical switches, etc., to achieve the effect of reducing over-travel, reducing distance, and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

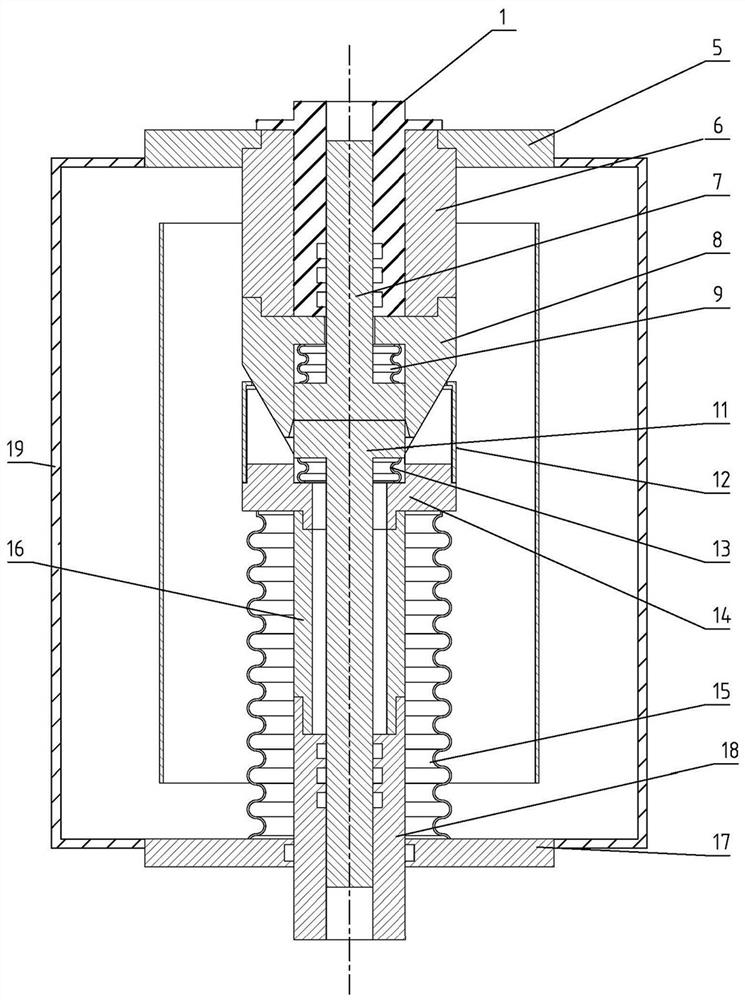

[0046] In the vacuum interrupter with compound contact structure provided by this embodiment, both the static arc contact 7 and the dynamic arc contact 11 can move relative to the corresponding main contacts, which can reduce the number of single static arc contacts 7 The moving distance can relatively reduce the space occupied by the static end of the entire vacuum interrupter, and optimize the overall performance of the vacuum interrupter.

[0047] The specific structure of the vacuum interrupter is as follows: Figure 1 to Figure 3 As shown, the vacuum interrupter in this embodiment includes an interrupter housing 19, and a static contact structure and a moving contact structure are arranged inside the arc extinguishing chamber housing 19, and the static contact structure is located above the moving contact structure. The arc extinguishing chamber housing 19 here includes a middle circumferential housing, an upper cover 5 at the upper end and a lower cover 17 at the lower e...

specific Embodiment 2

[0071] The main difference between it and Embodiment 1 is: in Embodiment 1, in the embodiment, the static main contact has a tapered outer peripheral surface, and the moving main contact has a tapered concave portion. In this embodiment, the moving main contact has a tapered outer peripheral surface, and the static main contact has a tapered concave portion, which can also realize the tapered mating of the two main contacts and effectively increase the contact area.

[0072] Generally speaking, the moving contact structure is arranged at the bottom, and the static contact structure is arranged at the top. In fact, in other embodiments, the moving contact structure can also be arranged at the top, and the static contact structure is arranged at the top. Arranged below.

specific Embodiment 3

[0074] It differs from Embodiment 1 mainly in that: in Embodiment 1, the tapered outer peripheral surface of the static main contact and the tapered inner peripheral surface of the moving main contact are both conical surfaces. In this embodiment, the tapered outer peripheral surface of the static main contact and the tapered inner peripheral surface of the moving main contact can also be pyramidal surfaces, but for the purpose of improving the electric field performance, the edges of the static main contact can be designed rounded structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com