Fracture toughness analysis method for pressure-bearing main equipment and chemical machinery pressure-bearing equipment of nuclear power plant

A technology for chemical machinery and pressure-bearing equipment, applied in design optimization/simulation, testing material strength using stable tension/pressure, special data processing applications, etc. problems, to achieve the effect of improving economy and calculation efficiency, increasing the probability of fracture occurrence, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

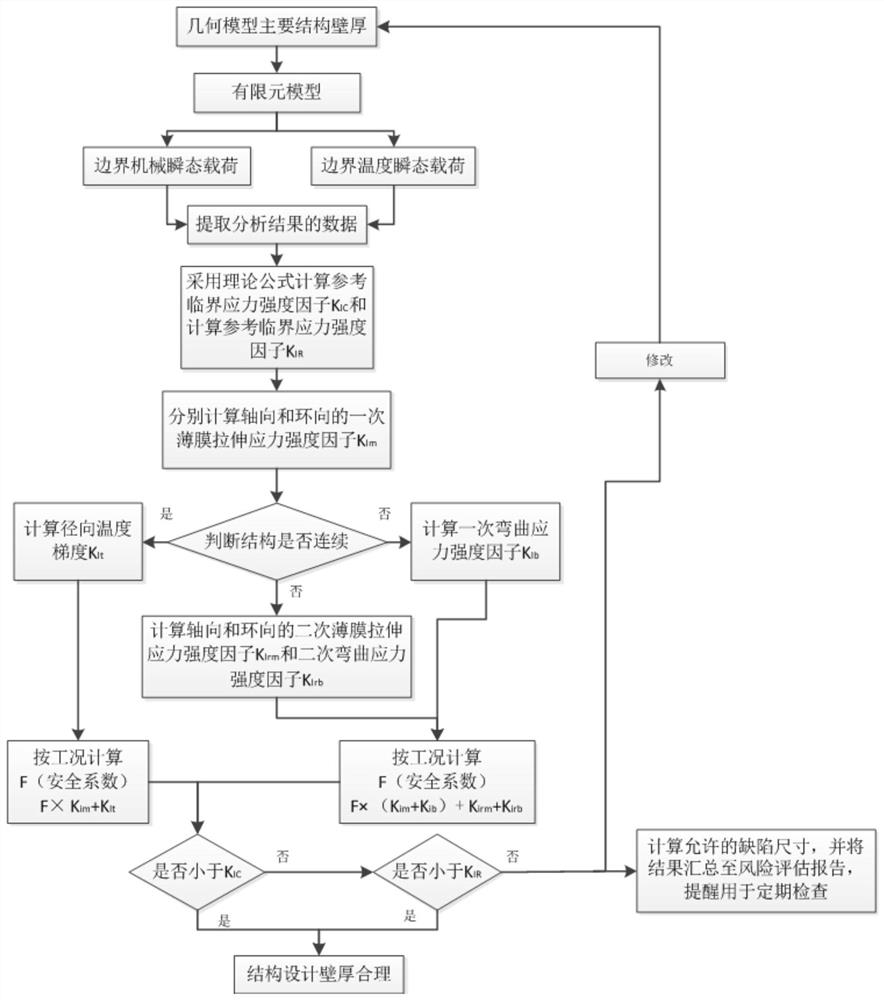

Method used

Image

Examples

specific Embodiment approach

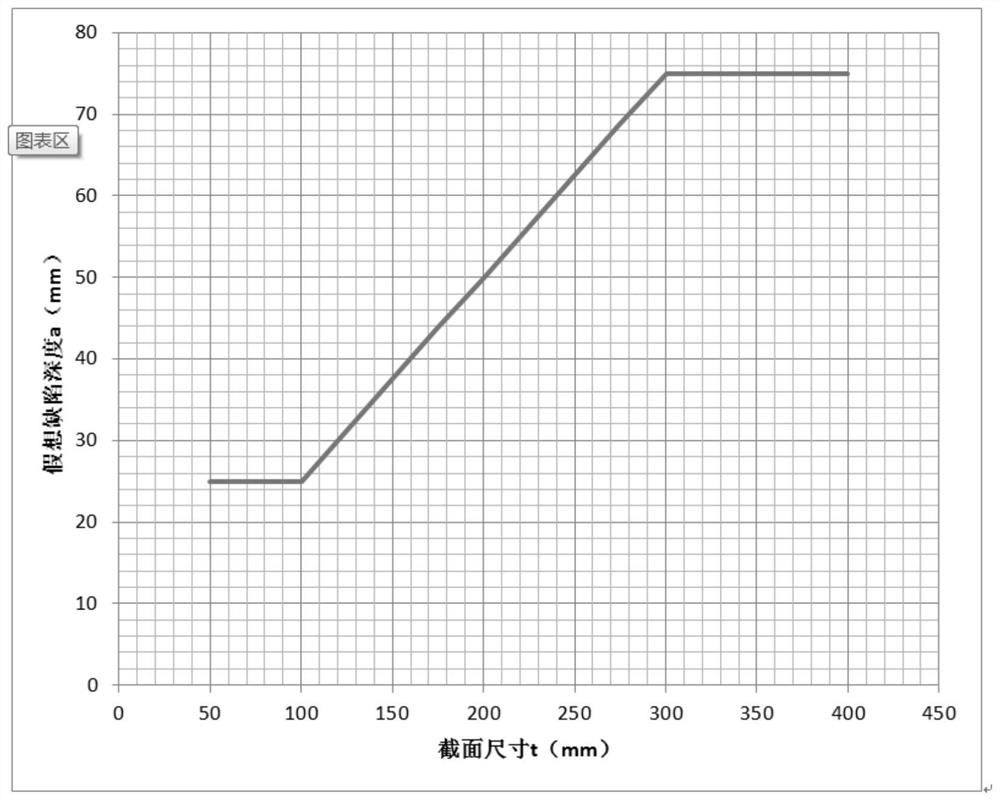

[0081] Specific implementation method: according to the requirements of imaginary defects, for a section with a thickness from 100mm to 300mm, the imaginary defect depth (a) is 1 / 4 of the section thickness, and the length (2c) is taken as 1.5 times the section thickness, that is, the aspect ratio is ( 2c / a=)6:1, the defect is assumed to be on the inner and outer surfaces; for a section greater than 300mm thick, the imaginary defect of the 300mm thick section is used; for a section less than 100mm thick, the hypothetical defect depth is conservatively assumed to be 25mm. The cross-sectional size of the combined path P01 is 80.4 mm, which is less than 100 mm, so the imaginary maximum defect depth is taken at 25 mm from the inner and outer surfaces, that is, the surface crack refers to the cross-sectional thickness where the crack depth (a) is less than 0.7 times; the deep buried crack refers to the crack depth (2a ) is less than 0.7 times the section thickness, otherwise it is a ...

specific Embodiment approach 2

[0211] Specific embodiment two: according to the description of specific embodiment one 4.2 calculation steps, this calculation step can also select the following alternate calculation methods:

[0212] British system;

[0213] metric system;

[0214] T: temperature at defect, ℉ / ℃;

[0215] RT NDT Reference no-ductility transition temperature, ℉ / ℃;

[0216] K IR : crack growth resistance, take K Ia and K IC the smaller value of

specific Embodiment approach 3

[0217] Specific implementation mode three: according to the description of specific implementation mode 1 5.2 calculation steps, this calculation step can also select the following alternate calculation methods::

[0218] This method is based on the strength factor resulting from mechanical loading, for the tensile stress intensity factor resulting from mechanical loading:

[0219]

[0220] For the bending stress intensity factor resulting from mechanical loading:

[0221]

[0222] m k : film stress correction factor; M B : Bending stress correction coefficient; a: Defect depth; m; Q: Defect shape correction coefficient in plastic zone;

[0223]

[0224]

[0225] σ m : primary film stress; Mpa

[0226] σ b : primary bending stress; Mpa

[0227] After considering the effect of thermal stress, the revised total stress intensity factor:

[0228]

[0229] σ M : secondary film stress; MPa

[0230] σ B : secondary bending stress; MPa

[0231] F: safety factor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com