Wagon balance weighing support device and installation method thereof

A technology of weighing and weighing scales, which is applied in the direction of measuring devices, protection devices, weighing vibration damping, etc., can solve problems such as limited pressure bearing capacity of the foundation, inconsistent loads, and reduced service life of the weighing scales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

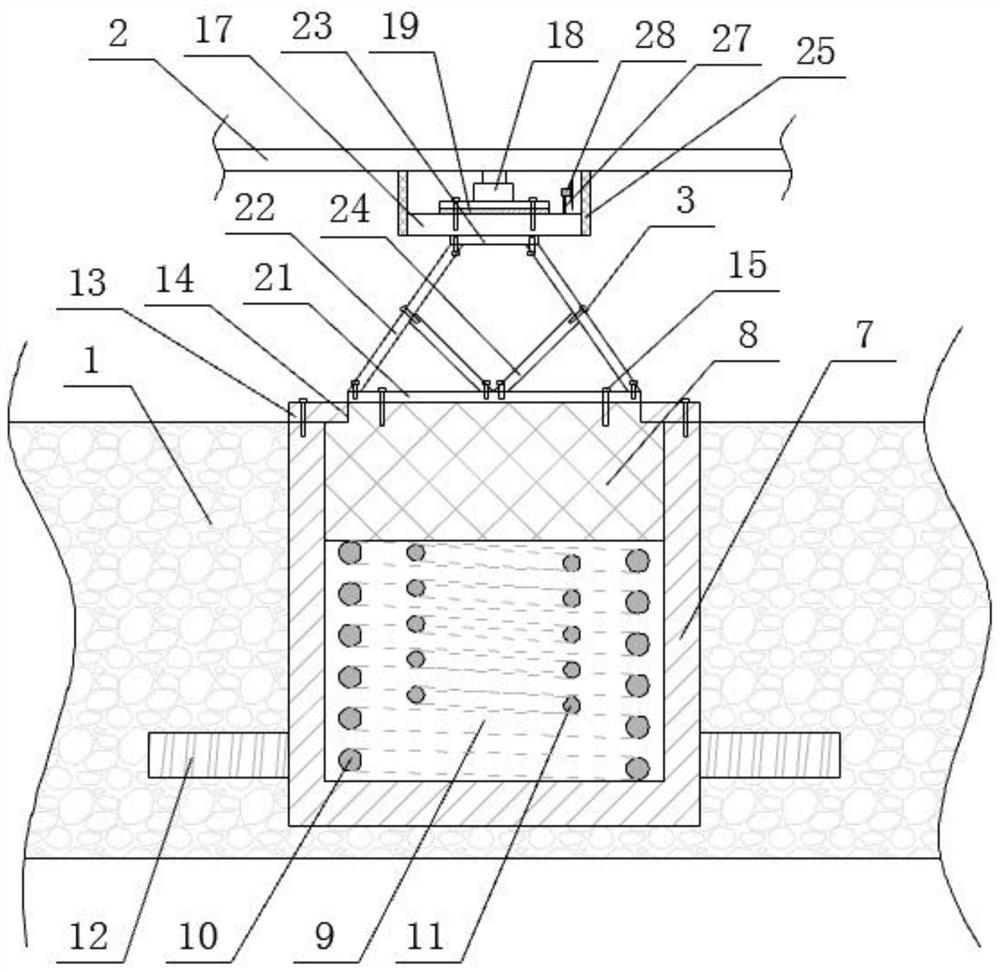

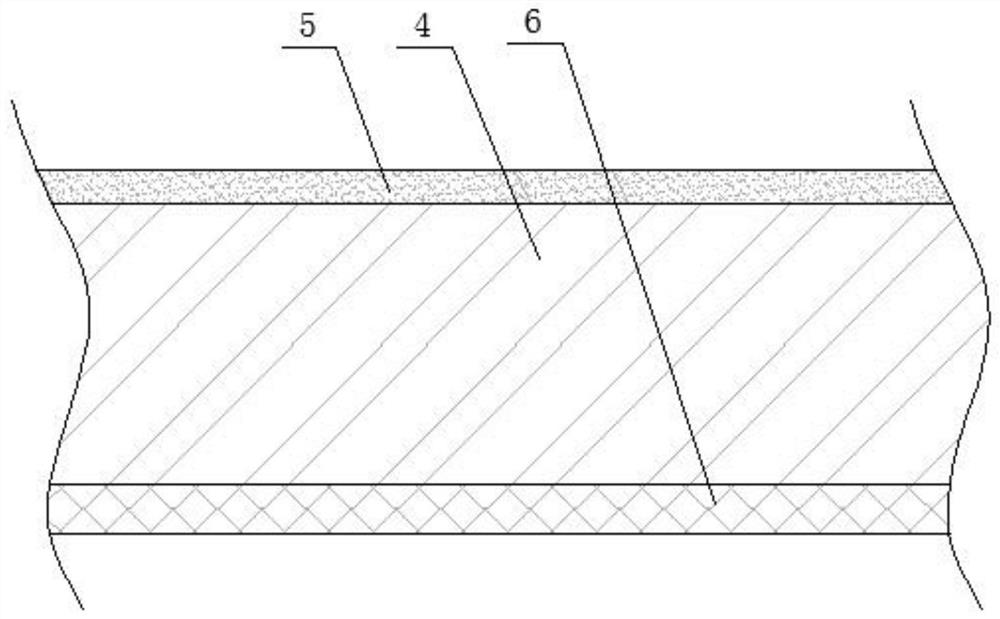

[0031] see Figure 1~6 , in an embodiment of the present invention, a weighbridge weighing support device includes a base 1 and a weighing platform 2, the main body of the base 1 is cast from a reinforced concrete layer 4, which improves the pressure bearing capacity of the foundation, Provide a stable foundation for the weighing process and improve the service life of the weighbridge. The top of the reinforced concrete layer 4 is sprayed with a hydrophobic layer 5, and the bottom of the reinforced concrete 4 is provided with a rigid waterproof layer 6, so that the use environment of the base 1 remains good. It will be corroded by water, which improves the service life of the base 1 .

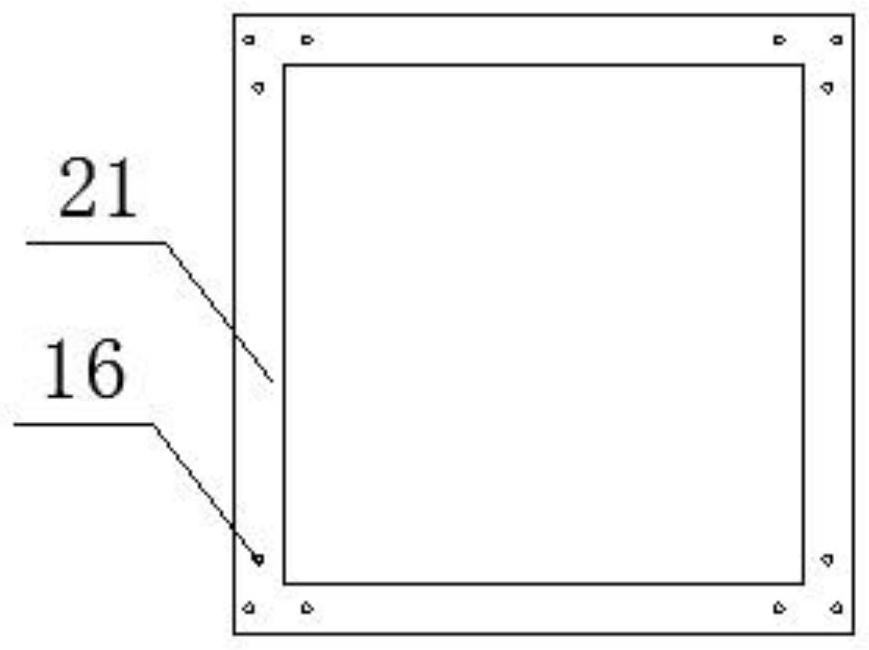

[0032] Preferably, the top of the base 1 is provided with an embedded part 7, and the embedded part 7 is in the shape of a hollow column, so that the pressure bearing area of the base 1 is larger, effectively reducing the pressure on the base 1 during the weighing process, and improving To e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com