Split type combined frog

A split and frog technology, applied in the field of rail transit, can solve the problems of restricting the transportation capacity of heavy-duty lines, high manufacturing costs, and short frog life, so as to improve the quality and efficiency of single-piece cooperation and reduce the forging of high manganese steel or alloy steel quality, the effect of improving manufacturing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

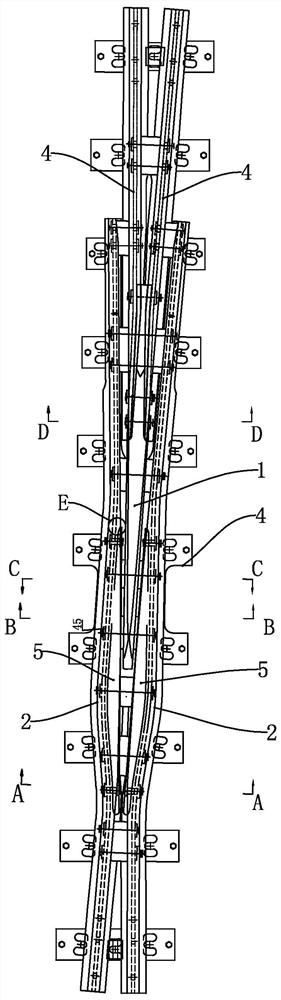

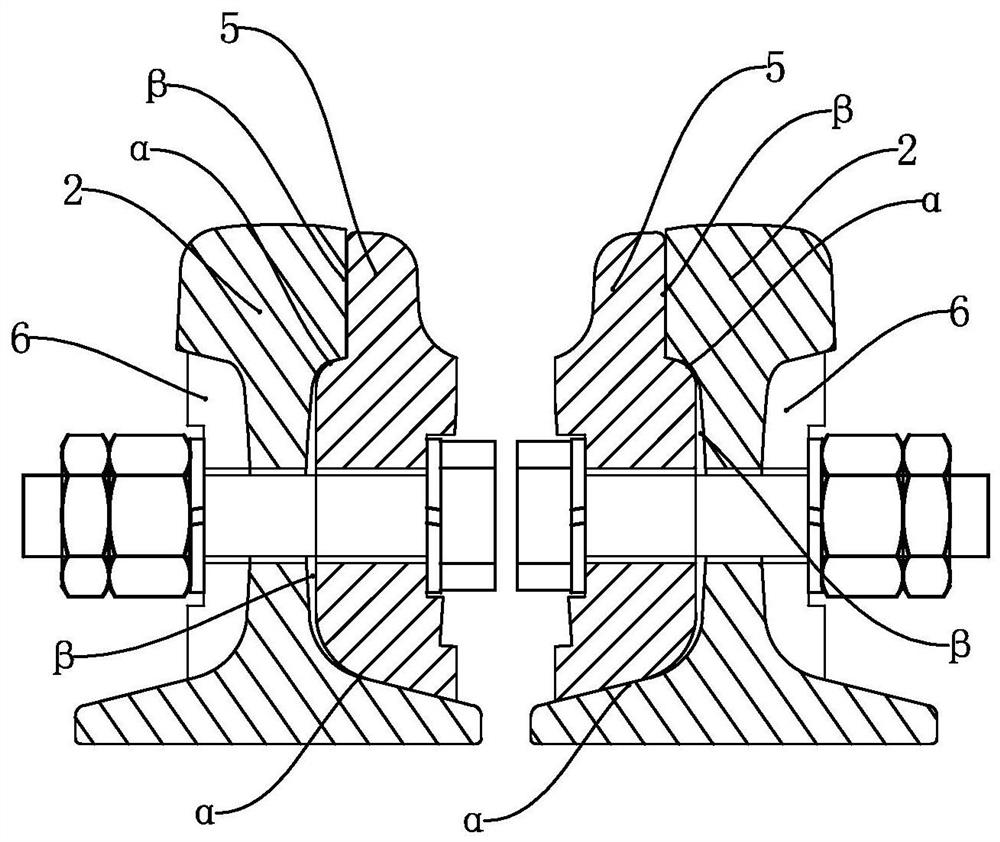

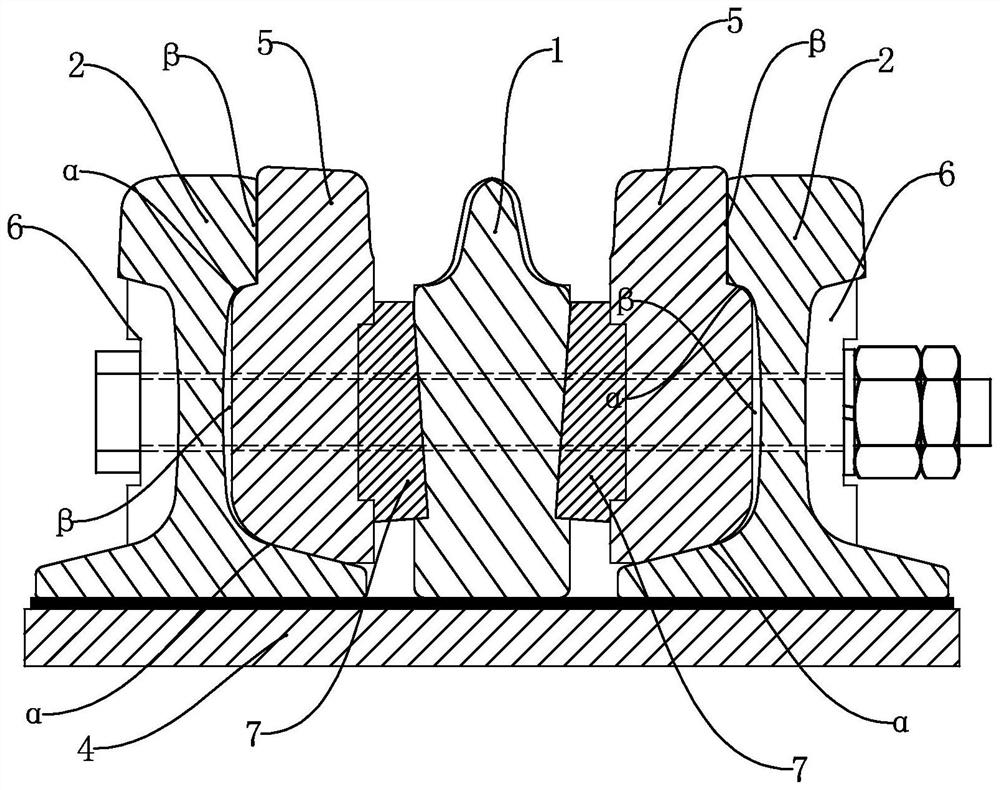

[0026] Such as figure 1 The shown frog includes a center rail 1, a pair of wing rails 2, a pair of fork heel rails 3 and a pair of mosaic blocks 5, and the wing rails 2 are symmetrically arranged on both sides of the core rail 1, as shown in figure 2 The mosaic blocks 5 shown are all installed on the inner side of the wing rail 2 through bolt pairs, as shown in Figure 5 The shown fork and rail 3 are symmetrically arranged on both sides of the core rail 1 and are installed on the core rail 1 through bolt pairs, as shown in image 3 with 4 As shown, a spacer iron 7 is set between the core rail 1 and the mosaic block 5, such as Figure 2 to Figure 5 As shown, an anti-rotation steel washer 6 is provided on the outside of each bolt pair connection; since the core rail 1 and the mosaic block 5 are in the most vulnerable parts, the core rail 1 and the mosaic block 5 are made of forged high manganese steel or alloy steel Compared with the traditional integral high manganese steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com