Cavitation unit for enhanced cellulose pulp refining production

A cellulose pulp and cavitation technology, applied in cellulose pulp post-processing, fiber raw material processing, papermaking, etc., can solve the problems of limitations and high energy consumption, and achieve the effect of improving efficiency, high efficiency and good utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

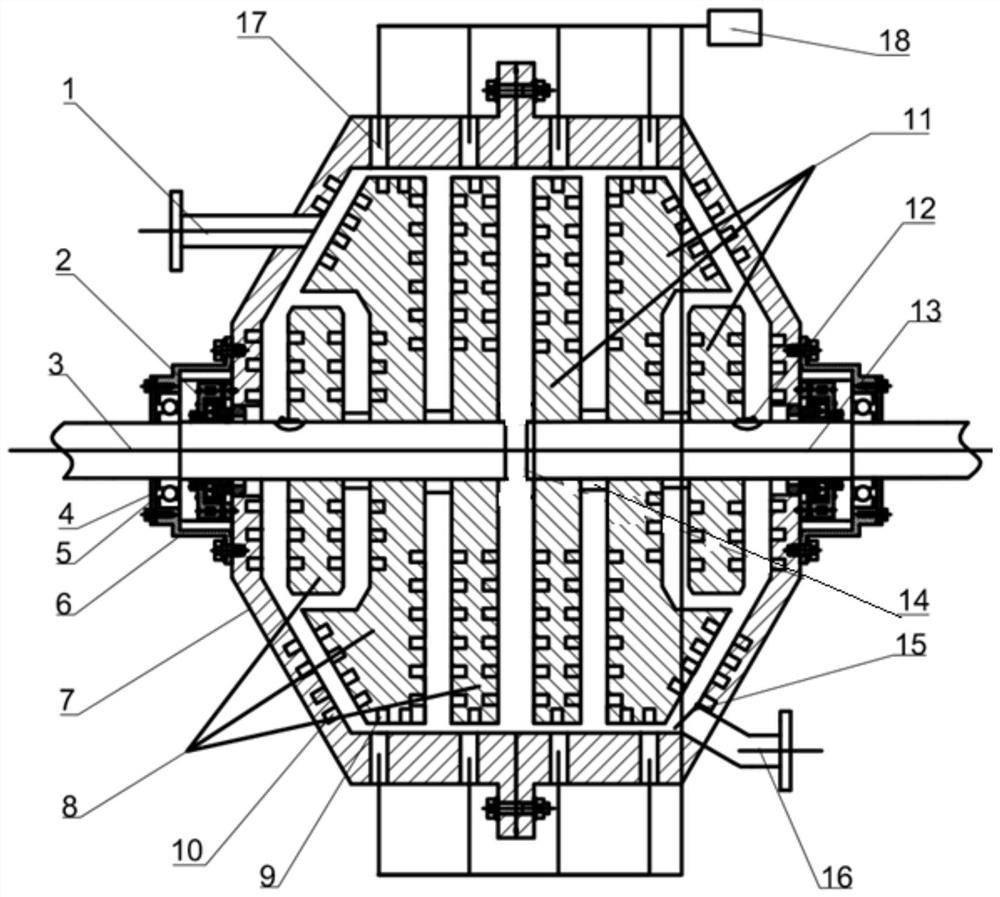

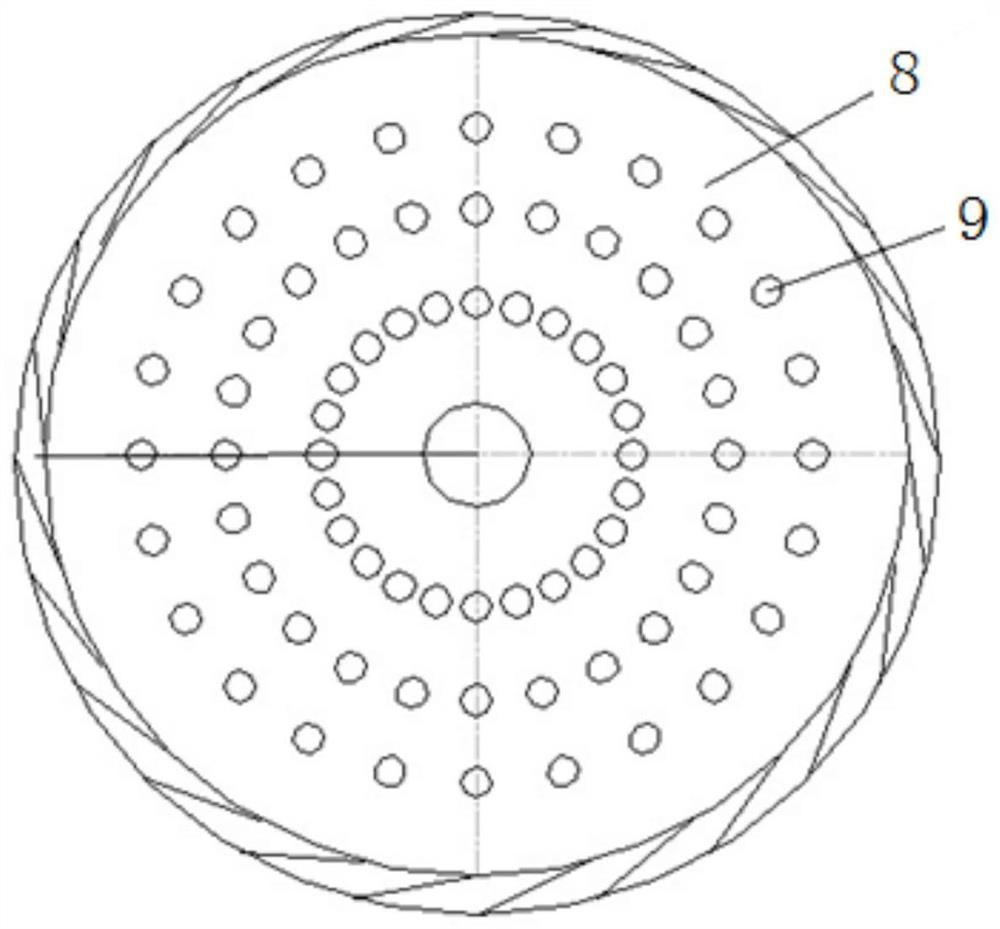

[0034] The cavitation device for refining production of reinforced cellulose pulp of the present invention, such as figure 1 As shown, it includes a stator 7, a rotating shaft, a rotor and an ultrasonic transducer 17. The rotating shaft includes a first rotating shaft 3 and a second rotating shaft 13 . The rotors comprise a first set of rotors 8 and a second set of rotors 11 .

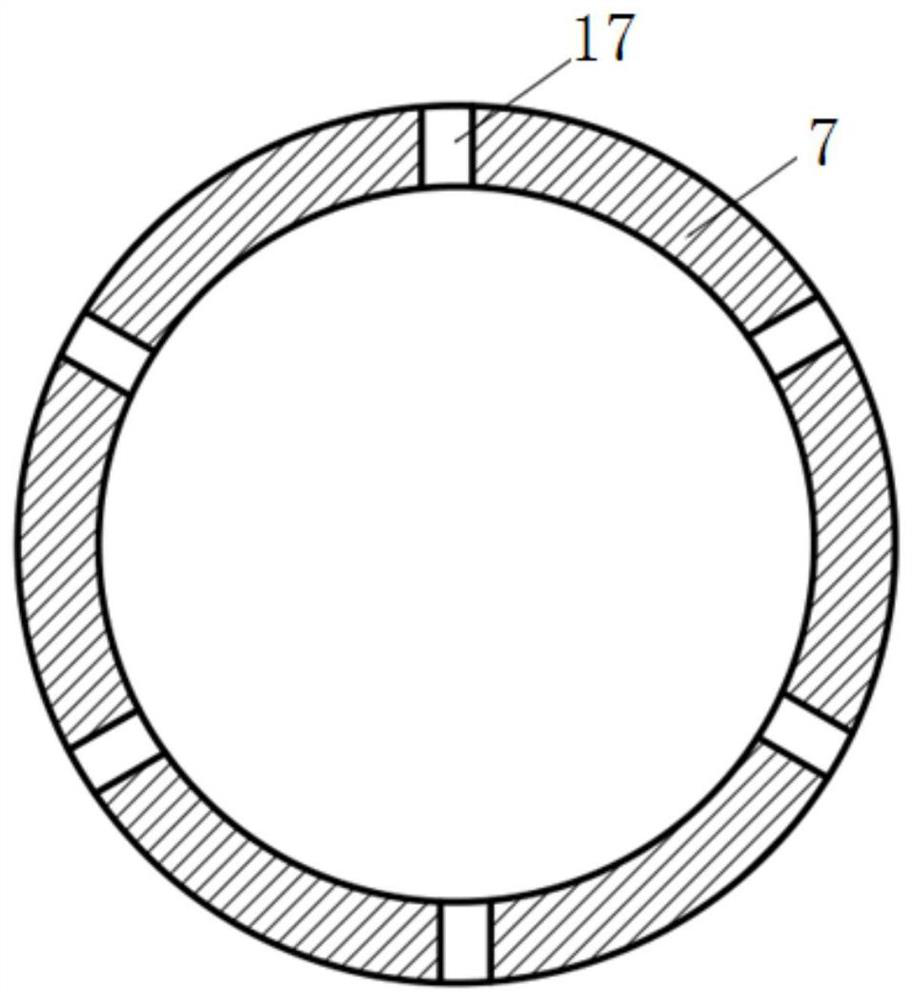

[0035] The stator 7 is a closed cylinder, which is enclosed by two half-shells, and the outer sides of the two half-shells are tapered. Ultrasonic transducers 17 are distributed on the inner wall of the stator 7 . Each ultrasonic transducer 17 is connected with an external ultrasonic generator 18 to induce ultrasonic cavitation. see figure 2 , the ultrasonic transducers 17 are embedded in the inner wall of the stator 7 along the axial and circumferential directions in the form of 2 to 8 ultrasonic transducers at equal intervals. The number of ultrasonic generators 18 is 1-4, the frequency is 40-8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com