Rail TIG welding method for black-and-white pipes

A welding method and track technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of restricting wide application, prone to concave, concave, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

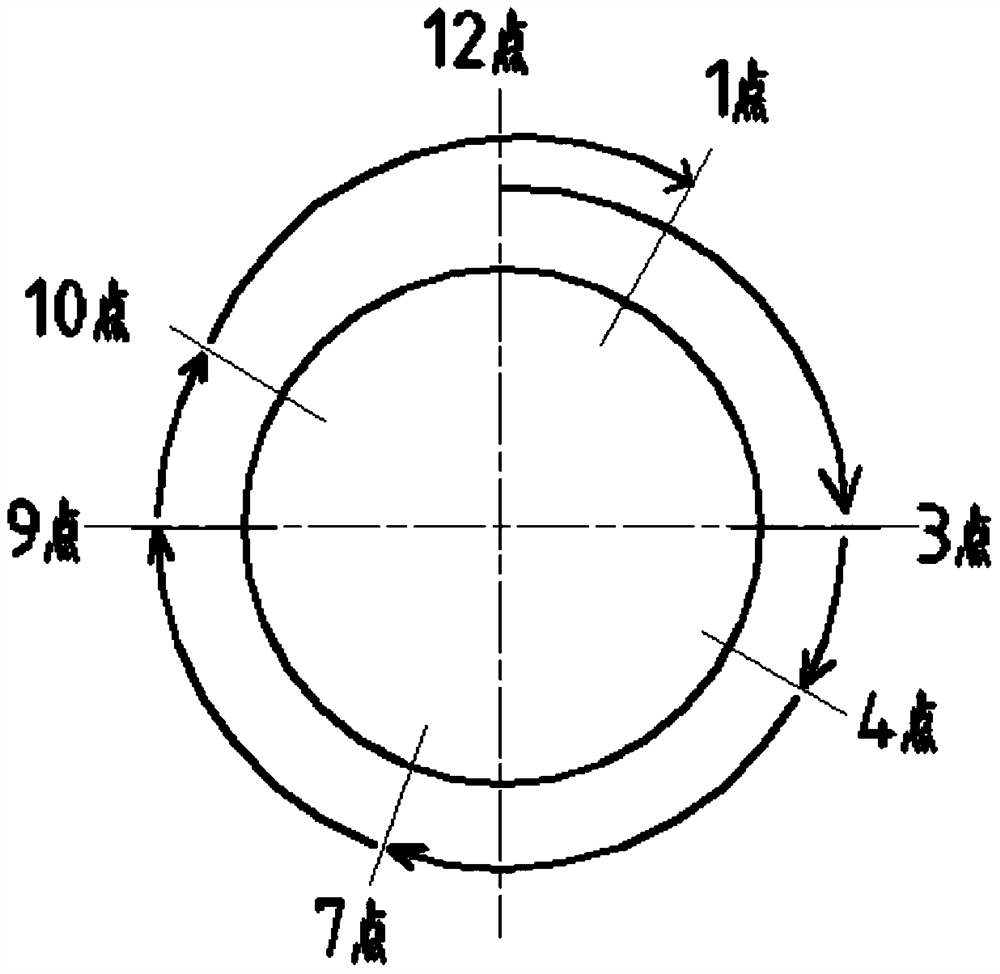

[0028] The invention provides a welding method for orbital TIG welding of black and white pipes. Such as Figure 1 to Figure 5 shown. The welding method includes the following steps:

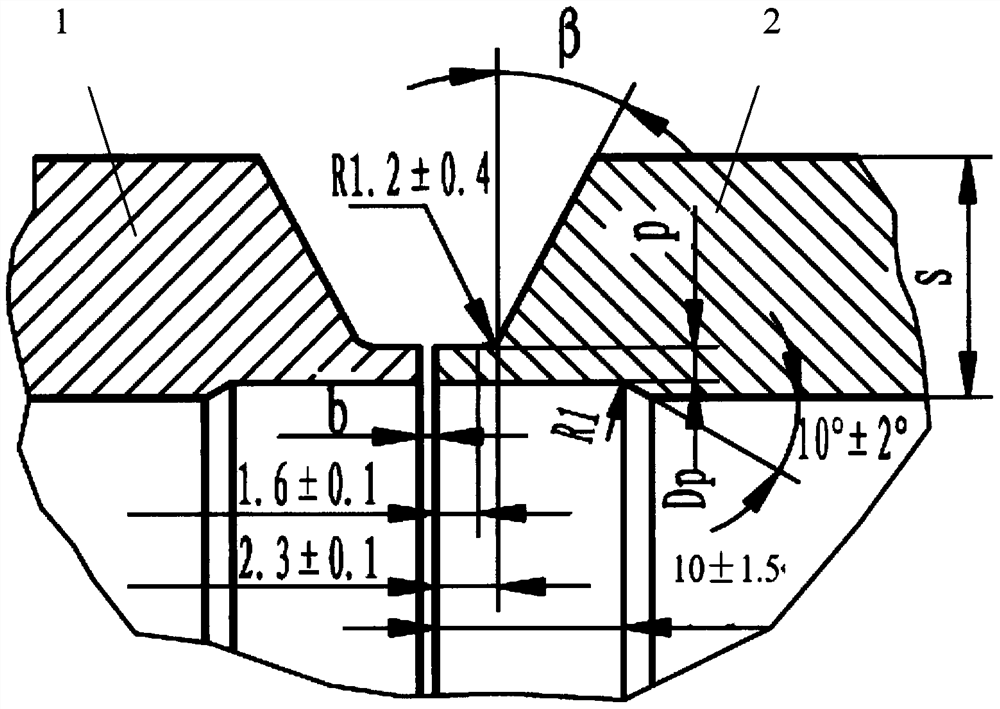

[0029] Step 1: Machining the welding grooves of the T91 / T92 pipe 1 and the austenitic stainless steel pipe 2 by means of mechanical processing. Groove size such as figure 1 shown. J-shaped groove is adopted. In order to ensure the quality of the track TIG welding groove, the inner wall of the pipe needs to be processed with a welding inner diameter Dp, Dp=Dw-1.8S, where Dw is the nominal outer diameter of the pipe, and S is the nominal thickness of the pipe. When the pipe wall thickness S≤16mm, the blunt edge p of the groove is 1.6mm, and the length of the blunt edge is 1.6mm. 28°.

[0030] Step 2: Grind the area to be welded to see the metallic luster, do no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com